Kniterate, the knitting machine inspired by 3D printing

Ever wanted to create your own clothing without limits? Well now you can thanks to Kniterate, a knitting machine that uses techniques similar to those found in 3D printing. The founders of this Spanish startup, Gerard Rubio and Triambak Saxena, were inspired by classic 3D printers, which ultimately led to the development of their machine. Based on a digital production method, their machine gives you the opportunity to create and obtain any desired shape just by adding fabric and using a file from your computer.

Although this Startup has only launched its Kickstarter a few days ago, they have already managed to raise more than $490,000. To learn more about the Kniterate and what these two founders have in store for it, we decided to talk with one of the founders, Gerard Rubio, to find out.

3DN: How did you come up with the idea for Kniterate?

The idea came four years ago. At the time, I was working for a company called blablaLAB, which was dedicated to different projects and workshops around 3Dprinting- so this technology was an integral part of my daily life. Before this, I studied design in a fashion school where we had access to a lot of textile machines and different workshops that you could take part in, so I already had an interest in this field before working in 3D printing. On top of this, I have always liked to assemble and disassemble all kinds of things in order to understand how they work, and these textile machines always fascinated me. I knew I had to do something with them.

The two creators of Kniterate, Gerard Rubio and Triambak Saxena

For some time I studied this subject as well. After awhile, I began to think that if there were 3D printers that could be used at home to create objects from digital files, then why couldn’t we have a similar machine to create clothes? This reflection was the starting point. I think our answer to this is the Kniterate.

3DN: Can you explain to us the process that your machine uses?

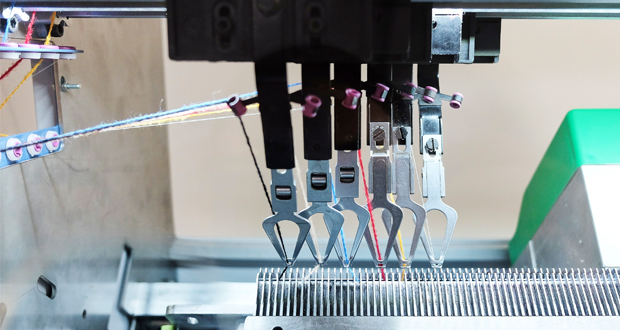

The process our machine uses is very similar to that of a conventional FDM printer. The Kniterate machine works with spools of fabric (such as cotton or wool) in the same way that an FDM printer uses a filament coil. You simply choose the color you want, the fabric, and you insert the thread into the tensioners and wire guides. After, your machine is ready to go!

Choose your colors and materials

To create your designs, you can use any typical 2D designing tools (Photoshop, Illustrator, etc.) or you can use the application that we are developing. Our application gives you the freedom to design your clothes using the provided templates. This gives you a base that allows you to easily create the patterns you want. You will also have the opportunity to share your creations with others in the community through a digital wardrobe.

Once your file is ready, all you need to do is save it to an SD card and then insert it into the machine. After, you select your file and press “Knit”. Once your garment is finished, it will come out on the lower shelf and your final steps will only be to cut the threads and make any final touches that you need.

3DN: What do you think the relationship is between the additive manufacturing and textile industries?

Between these two industries, they both have many different things in common depending on the method of textile production that is chosen. Most of the clothes that we wear are made by attaching different parts of fabric together. Because the different fabrics are cut from a large canvas, this method generates much more material waste since most of the original fabric is not used. It inefficiently mixes an additive (weaving the large canvas) and subtractive (parts are cut out with waste created) manufacturing process together.

When we look back to the Kniterate machines, we are able to work directly with additive manufacturing. This is because our machine gives us the ability to create parts that have the desired final shape that were looking for, without the waste of material and time when it comes to the post processing steps. This is exactly like what you find with a 3D printer.

3DN: What are the future projects you have for the Kniterate?

Currently, we are focusing on producing and delivering our machines on Kickstarter, in addition to developing the software that goes with it. We have a lot of ideas for the future, but for now we are focusing on delivering a quality product.

3DN: Any last words for our readers?

If you’re interested in our machine, you can have a large reduction in price by supporting our project on Kickstarter until May 8th. Don’t forget to check out all our photos and videos as well!

A quick video presentation of Kniterate:

Do you think that Kniterate will revolutionize the manufacturing of clothing? Let us know in a comment below or on our Facebook and Twitter page!