Detecting Keyhole Pores in Laser Powder Bed Fusion

Scientists from the University of Virginia, Carnegie Mellon University and the University of Wisconsin-Madison have developed a method to detect and prevent the formation of structural defects known as ‘keyhole pores’ which can result in additively manufactured parts with poor mechanical properties. With funding from the Department of Energy, the team used x-ray imaging and thermal imaging combined with multiphysics simulations to detect ‘keyhole oscillation’ in the laser powder bed fusion of a titanium alloy, Ti-6Al-4V.

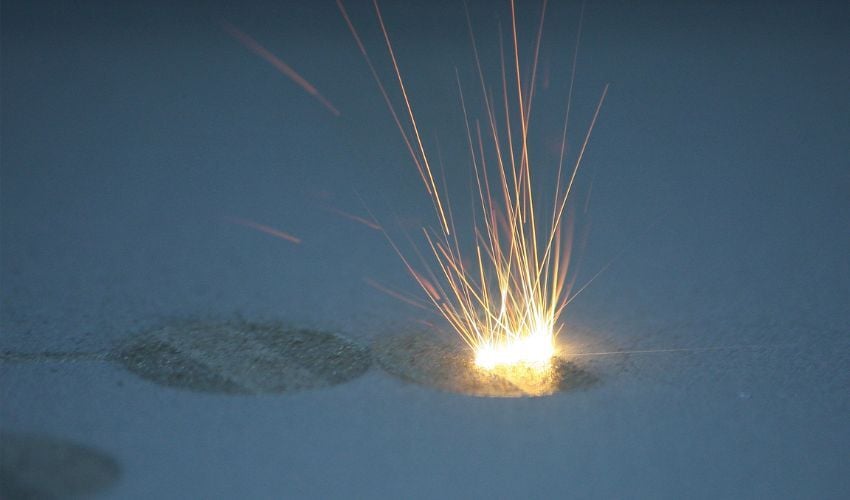

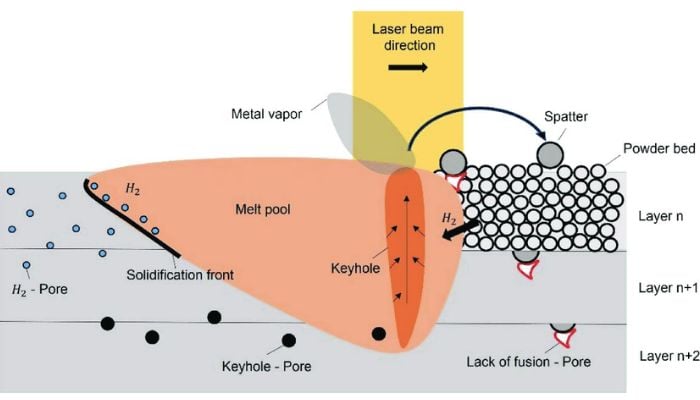

But what exactly are keyhole pores? Well, as you may know, laser powder bed fusion involves the melting and fusion of metal powder particles with a laser. One issue which this can cause is a keyhole pore (as shown in the cover image). These keyhole pores form due to excess laser energy input concentrated on a particular zone of the part. This causes metal vaporization to exert a recoil pressure, pushing down the melt pool surface – this being the area where the laser has melted the powder for sintering. The lowered pool forms a keyhole in which laser reflection and absorption occurs; these unstable conditions can lead to keyhole collapse, where gas bubbles form and can become pore defects when they are stuck in the material by the solid layers. These defects can increase part fatigue and be sites for crack formations in the future.

Pore formation in laser powder bed fusion (Photo credits: Natan Nudelis and Peter Mayr, licensed under Creative Commons 4.0)

How Applicable Are The Results to Industry?

The researchers, led by Zhongshu Ren and Tao Sun at the University of Virginia, developed a method to prevent these keyholes by using x-ray imaging, which indicated to them the tendency of keyhole oscillation. They used this information to build a machine-learning model which uses thermal imaging to detect these keyholes. They believe these results to be very applicable to industry 3D printing. Sun confirmed, “Our approach provides a viable solution for high-fidelity, high-resolution detection of keyhole pore generation that can be readily applied in many Additive Manufacturing scenarios.”

Interestingly in this project, the team did not only use physical experimental methods. They utilized machine learning. According to Zhongshu Ren, “This project truly changed my perception of machine learning… [it] is a great tool for scientific research and engineering applications, as long as its result can be interpreted.”

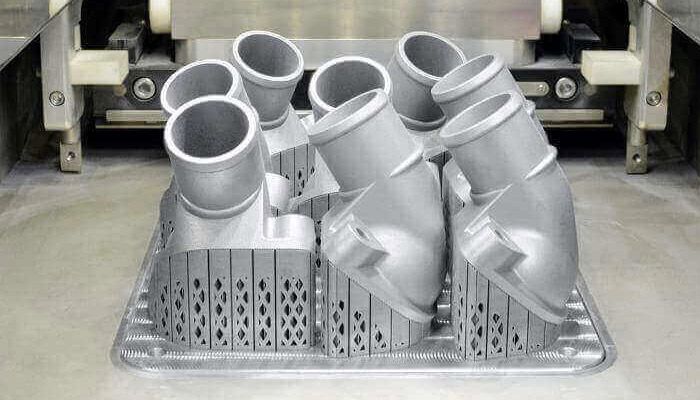

LPBF can make high-quality metal parts

Furthermore, the technique they used is easy to apply to other projects. According to them, the analysis of oscillation behaviors is ‘generic and practical’, meaning it is not exclusive to certain projects only. Engineers could use analysis to prevent keyhole pores, thus making parts with better structural and mechanical properties with a lower risk of failure. For more information on the scientific research, you can find the paper HERE.

What do you think of this laser powder bed fusion experiment on pore formation? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: GE Additive