Kexcelled Talks Its Range of 3D Printing Materials and International Expansion

As research into new additive manufacturing materials continues to advance, so do the suppliers of these materials. Kexcelled has established itself as a key player in the high-quality materials sector with a wide range of products including both filaments and resins. The company has recently undergone significant international expansion, opening subsidiaries in Europe and North America, positioning itself in key markets around the world. Its focus on quality and sustainability has been fundamental to its growth. To learn more about the company’s mission, its competitive strategy and its participation in the upcoming Formnext 2024, we spoke to Wilson Mao, founder and CEO of Kexcelled, who gave us insights into the company’s achievements and its outlook for the future of an ever-evolving market.

3DN: Could you introduce yourself and tell us about your connection with 3D printing?

Hi, I’m Wilson Mao, the founder and CEO of Kexcelled, a company dedicated to empowering individuals and businesses through innovative 3D printing material solutions. I’ve always been passionate about digital technology products, and I started my career as an IT engineer. My journey began over 12 years ago when I first encountered a desktop 3D printer. It was a transformative moment, akin to the early days of personal computing. I was captivated by the possibilities of bringing designs to life with the touch of a button. This experience ignited my passion for 3D printing, and I knew I wanted to be part of shaping its future.

On the left Wilson Mao, founder and CEO of Kexcelled.

3DN: What is Kexcelled? What is the company’s mission?

Kexcelled combines ‘key’ and ‘excellent’ reflecting our focus on fundamental material science and our commitment to delivering superior products. Kexcelled’s mission is to drive the advancement of 3D printing through innovative materials. We aim to become a leading force in the 3D printing materials industry, similar to renowned material science companies like Dow, BASF, or Gore-Tex.

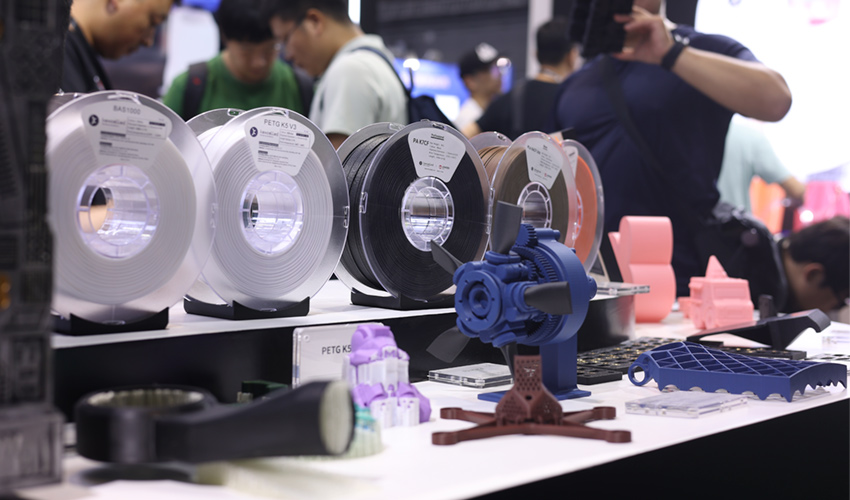

3DN: What variety of 3D printing materials do you develop and what applications are they mainly intended for?

Kexcelled offers a comprehensive range of polymer-based 3D printing materials for both FDM and MSLA technologies. Our product line includes high-performance engineering plastics, flexible materials, biocompatible resins, and more. These materials are used in various industries, such as fashion, footwear, dentistry, automotive, aerospace and more. For example, our flexible materials are great for making custom orthotics and prosthetics, while our high-temperature engineering plastics are suitable for producing prototypes and parts used in manufacturing. We are constantly innovating and exploring new materials and applications to meet the evolving needs of the 3D printing industry.

3DN: What specific factors influenced Kexcelled’s decision to open new subsidiaries in Europe and North America? Are there particular market demands or opportunities you are targeting?

Europe and North America have long been at the forefront of technological innovation, including 3D printing. By establishing subsidiaries in these regions, Kexcelled aims to deepen our collaboration with leading research institutions, manufacturers, and technology providers. We are particularly interested in partnering with organizations that are pushing the boundaries of 3D printing materials and applications.

Kexcelled offices.

With companies like BambuLab driving a new wave of 3D printing adoption, there has been a rapid increase in the technology’s reach and impact. So, having a local presence allows us to better understand and address the unique needs of our customers. We can provide faster response times, localized technical support, and tailored solutions to help them maximize the benefits of 3D printing.

3DN: Are you considering partnerships with local companies or institutions in these regions to facilitate your expansion?

Absolutely, we are actively seeking partnerships with companies and institutions in Europe and North America. We are particularly interested in collaborating on research and development projects, exploring new material formulations and applications. Additionally, we are open to strategic partnerships with distributors and resellers to expand our market reach. For example, we are open to exploring a partnership with a European 3D printer maker to develop co-branded material solutions optimized for their specific hardware.

3DN: Looking ahead, how do you see Kexcelled evolving in the next five years?

In today’s world marked by considerable uncertainty, Kexcelled, as an enterprise, is focused on two key objectives for the next five years: ensuring our sustainability and fostering growth. We aim to create products rooted in core innovations. Our international subsidiaries will be instrumental in successfully navigating these challenges and spearheading technological advancements.

3DN: Any last words for our readers?

Layer by layer, to achieve excellence. You can find more information about Kexcelled on the website, HERE. Don’t forget to visit these 3D printing material solutions during Formnext 2024 at stand G19 in hall 12.1.

What do you think of Kexcelled’s solutions and its expansion strategy in Europe and North America? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All photo credits: Kexcelled