Jonathan Jaglom Talks Breaking the Mold in AM and 3D Printing Lenses With flō

Though often thought of as a relatively new technology, especially as compared to traditional methods, additive manufacturing has been around for quite some time now. The technologies have evolved far beyond the first iterations in the 80s to the constantly improving and innovative processes that we see today. And of course, the key to that are people, including those who have been in the industry for a long time. Among these we can count Jonathan Jaglom, a true veteran in the sector who recently also launched a new company dedicated to additive manufacturing for ophthalmic applications with a fascinating new process. We sat down with him to learn more about his experience, flō, and moving out of a box-mindset to truly advance in new AM applications.

3DN: Could you introduce yourself and your background in 3D printing?

My name is Jonathan Jaglom. I have been a veteran in 3D printing for the last +/- 20 years. I started at Objet Geometries (later to become Stratasys) in 2005 as a Sales Manager and helped build our presence in Europe. Next, I was briefly the Marketing Director of Europe before becoming Business Manager Customer Support. Come 2009, I was Application Director of Objet (later to become VP Sales Operations). In 2012, I was Team Lead in the integration of Stratasys and Objet on matters of Sales Readiness. Towards the end of 2012, I moved to Hong Kong and led the Asia Pacific Operation (General Manager APJ). I was P&L owner of this distribution unit (DU), carrying some 200+ staff and close to $150M at the time. In 2015, I became the CEO of MakerBot (initially +600 staff) and helped in its PMI (post merge integration) process into Stratasys. I left Stratasys in 2017.

Jonathan Jaglom, the CEO of flō is well-established in the AM industry

My career at Stratasys gave me tremendous exposure in how operations run, as I was able to lead most activities existing in S&M (Sales & Marketing). Of course, many positions required a lot of work with Finance, R&D, Operations and HR, so again a lot of know-how was gained. When I left Stratasys after my 12-year tenure, it was clear to me that I wanted to take what I had learned from the operational arena and seek the next opportunity in Additive, but not in the form of a box-mindset AM solution. What I mean by that is in finding a use case and building a platform around it, rather than building a platform to then seek the use case (the latter regretfully happens all too often in AM).

I embarked on a long journey of search, seeking to find my next opportunity, both as an investment I can pursue and one where my operational expertise can be applied. After almost 3 years of search (COVID-19 included), finally the stars aligned themselves and I came across the perfect opportunity: flō.

Today I am the CEO and Chairman of flō and I have been involved with the company since 2021 under stealth mode. We only recently revealed ourselves to the world. Exciting indeed!

Jonathan Jaglom, the CEO of flō is well-established in the AM industry

3DN: You speak about the search for an application that isn’t “box-mindset,” how do you see the use of AM in other solutions/verticals?

Organizational culture in any company is very difficult (arguably almost impossible) to alter over time. Once established, a culture is deeply rooted in the company ethos. Stratasys, from very early on, placed significant focus on technology and delivering the best products in the form of a “box-mindset”. We would showcase our platforms and seek customers that could use our platforms as ‘general purpose solutions’. Being that 3D-printing was so innovative at the time, the focus was really to bring the technology to market, the customer then needing to select which system best suited his/her needs. This was the culture. In a nutshell, it was RP-driven & general-purpose platform motivated. Times have since changed.

Today’s environment is abundant with platforms, all trying to find that niche use case that justifies a certain company’s existence. A certain material, a feature in printing…all play a key role in differentiating one from the other and enhancing UPS (Unique Selling Points). Yet still, focus is on technology and how it can overcome a certain problem. Less focus is put in pinpointing a problem and building a solution. What attracted me about flō is that the problem was clearly stated, but the solution wasn’t. Although all agreed any solution would most likely be AM technology-led. Intuitively, this is what we all felt. And we were right.

3DN: Could you tell us more about flō?

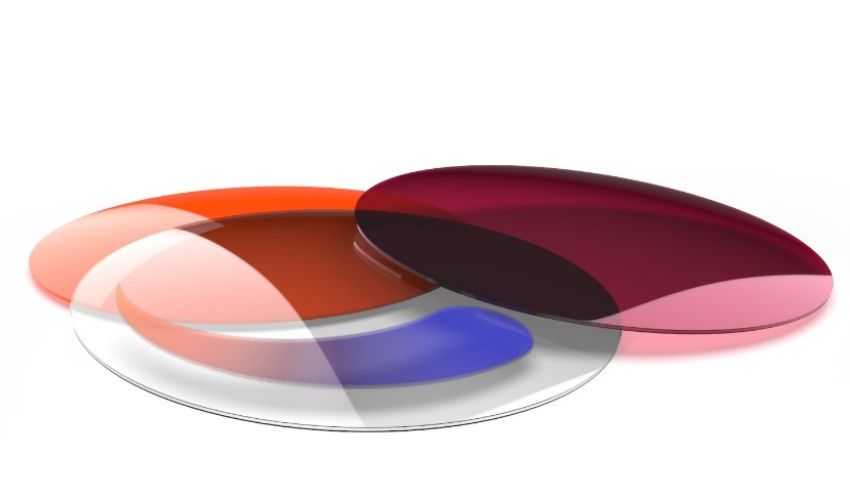

flō is using AM to resolve the complex problem in today’s ophthalmic industry (eyewear) around coatings. Coatings play a pivotal role in any lens creation (there is no such thing as a lens that isn’t coated. It could be hard-coated, tinted, anti-reflective, photochromic, or other). The process of coatings today is labor-intensive, limited in possibilities and costly, where various coatings require various systems. On the other hand, every individual’s lens (power, coating, cut) is different.

Enter Additive.

We all know that additive’s main raison d’être is around short series production processes. Clearly this is where AM is, and will continue, to play a huge role in the manufacturing world. So, we embarked on a journey to see how we can apply multi-layering and multi-material technology to better serve the ophthalmic coating market.

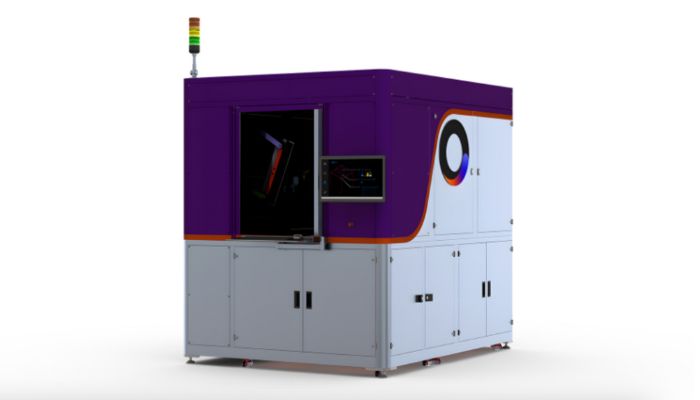

The solution offered by flō

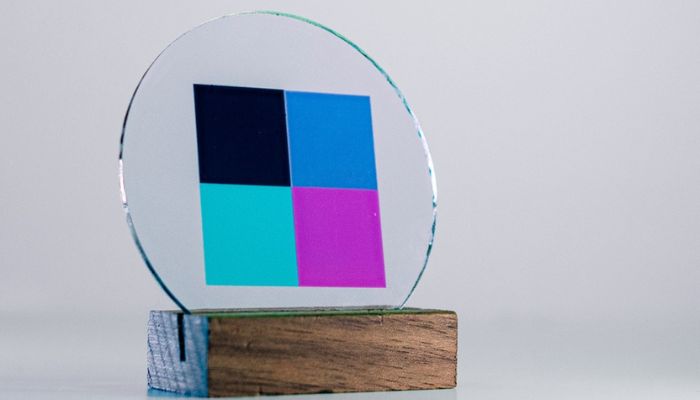

More specifically, in our technology, which we refer to as digital printing, we use ink-jet technology to jet materials that have both optical clarity and a certain functionality (for example protective layers, anti-reflection, tints, photochromic properties, antifog and blue light, among others). But to create these coatings, the material must be jetted very accurately as it is on surfaces significantly smaller than anything jetted in digital printing. These surfaces are not flat so we are also jetting on a curve. flō is the first company to ever jet such fine droplets on a non-flat surface. Moreover, no one before us has tried to jet coatings on lenses. Suffice to say, this is no easy printing technology to master.

3DN: Why is 3D printing suited to the field of optics?

We prefer using the term additive manufacturing at flō, not 3D-printing. We are definitely stacking layers of different materials, but there are no overhangs where support is needed so in that sense it’s not 3D. In any case, AM is very suited in the field of optical coatings because every lens is different, every coating is different and using AM gives you more precision at a pixel level. Such a level of precision gives you the ability to improve the functionality of certain coatings as mentioned above. This kind of multi-layering, multi-material process is something that is not done today as we are talking very fine layer coatings.

Just think of color for instance. Today tinting of coatings on ophthalmic lens is done in a wet process where the lens is dipped into a dye and then taken out to dry. If the lens is placed too long in the vat, if the room is overly humid, if the labor is not experienced… things can go wrong. But in the digital world of printing, we can print infinite colors accurately and consistently. As simple as that may sound as an advantage, for ophthalmic applications that is a radical change.

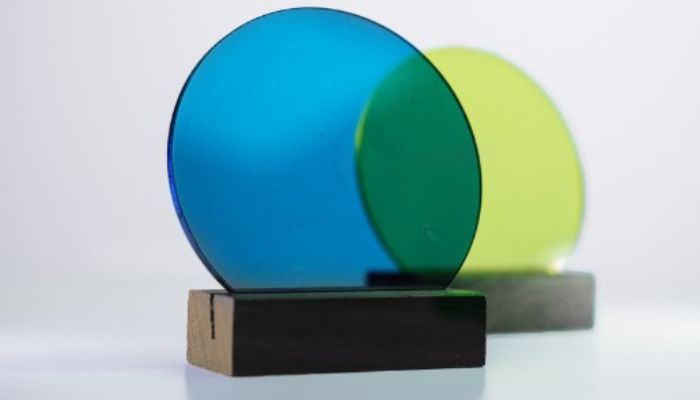

flō is able to create lens with coating with its multi-layering, multi-material process

3DN: What is the recipe for success in your opinion?

I think any company’s success rests around its purpose. Identifying a solution to a given problem and tailoring it such that the target audience will opt to acquire it is at the forefront of any successful company. With that in place, it’s all about strategy and ensuring that your play is long term, not opportunistic. You must read what the industry needs today, in 5 years and in 10 years, what the customer journey will look like in those various moments in time, and what will your competition do to try to fetter your efforts. You must draw all those vertices into a concise and well-thought-out play as part of your strategic roadmap.

And surrounding all that, whether it’s the Product, Technology or Strategy…is of course your Team. I have always been a great believer that companies are only as good as the people that hold all together. Here at flō we have the best talent possible, and one of our Values is:

‘Recruit & Retain Top Talent. We Never Compromise on Talent. Ever.’

Given that I am no newcomer to the AM world, I’ve built strong relationships over time that has allowed flō to really pull into the company the best possible talent out there. We have an amazing team! And we need just that to overcome a very challenging technology, as I explained earlier.

Examples of lenses made by flō

3DN: Any last words for our readers?

It is important to state that the same group of investors of Stratasys are those of flō. I represent a family that has invested in printing for some 30yrs. Our investment strategy is very focused; we commit to an opportunity both financially and operationally with a very long-term vision at hand. Our goal is to disrupt industries with innovative technology, and we are committed to whatever is needed for that to happen. Stratasys was 20 years in the making and today is the #1 leader in AM. Our goal is to do the same with flō. You can learn more about us HERE.

What do you think of this idea of making the solution to solve a problem rather than vice versa? Would you be interested in learning more about flō? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

It is possible to say that this 3D printing lenses are awesome. I appreciate them