Is Stabilizer Residue in Inks Inhibiting Conductivity in 3D Printed Electronics?

Researchers from the University of Nottingham have revealed that stabilizer residue in additive manufacturing inks function to inhibit conductivity in 3D printed electronic devices. While it was previously thought that the principal cause of reduced vertical conductivity through a printed device was shape and physical continuity problems at the interfaces of the constituent nanoparticles (at the very small micro and nanoscale), this study demonstrates otherwise. Instead, using silver nanoparticles, Nottingham researchers were able to show that reduced vertical conductivity is in fact caused by organic chemical residues in the inks.

One of the most commonly used types of conductive materials for printed electronics are inks which contain metal nanoparticles. By inkjetting layers of metal nanoparticle materials, users are able to achieve unprecedented design flexibility, rapid processing and 3D printing of functional electronic devices such as sensors, solar panels, LED displays, transistors and smart textiles. Normally, inkjet 3D printing of metals will form solid printed objects by first evaporating the solvent upon printing, also known in this case as pinning, and subsequently sintering, which is to say the low temperature consolidation of nanoparticles. This second stage is of particular importance as in many applications nanoparticles are co-printed with other functional/structural organic materials that are sensitive to higher temperatures, and as such low temperature is cardinal.

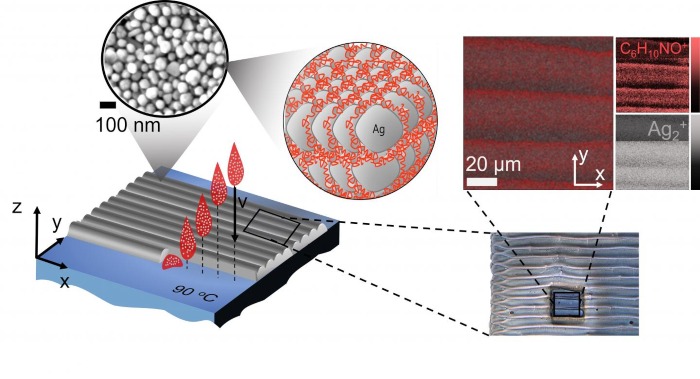

(left) Digital inkjet printing of inks containing metal nanoparticles with in-situ solvent evaporation (pinning). (right) Optical and chemical images of a printed layer of silver nanoparticles showing organic residues at the surface. (Photo Credit: Gustavo Trindade)

However, in an effect known as functional anisotropy, layers produced by inkjet printing of metal nanoparticles have different electrical conductivity between horizontal and vertical directions. This is a longstanding problem when it comes to 3D printing functional electronic devices and has prevented the technology from being used for advanced applications. As the study’s lead author, CfAM Research Fellow Dr Gustavo Trindade, explains, “The conductivity of inkjet-printed metal nanoparticles is known to be dependent on processing temperature and have been previously attributed to changes in the shape and porosity of clustered nanoparticles, with the role of organic residues being only speculated.” These residues are added to the inks for the purpose of stabilising the nanomaterials, but also end up forming low-conducting, very thin nanoscale layers which interfere with the electrical conductivity of the printed sample in the vertical direction.

The team believe that with a clearer understanding of how the residual organic additives are distributed within printed layers, they will be able to continue to define novel techniques and develop new ink formulations to overcome functional anisotropy of inkjet-based 3D printed electronics. Dr. Trindade concludes, “This new insight enables the development of routes to overcome functional anisotropy in inkjet-based nanoparticles, and will therefore improve uptake of this potentially transformational technology, making it competitive with conventional manufacturing. Our approach is transferable to other nanomaterial-based inks including those containing graphene and functionalized nanocrystals, and will enable the development and exploitation of both 2D and 3D printed electronics like flexible and wearable sensors, solar panels, LED displays, transistors and smart textiles.”

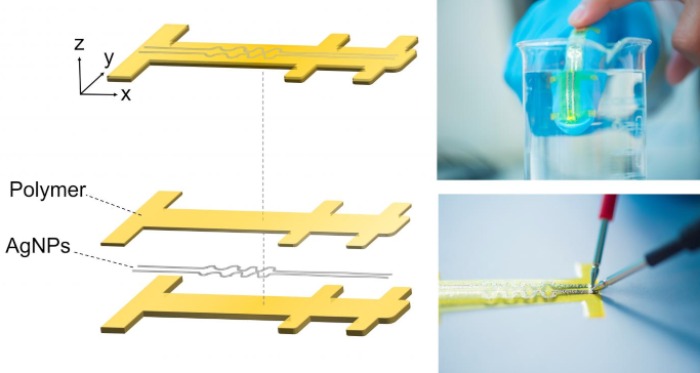

A multi-material inkjet 3D printed prototype of an encapsulated strain sensor used in the study. (Photo Credit: Gustavo Trindade)

If you want to find out more information you can read the full press release HERE. What do you think about this new research from the University of Nottingham? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

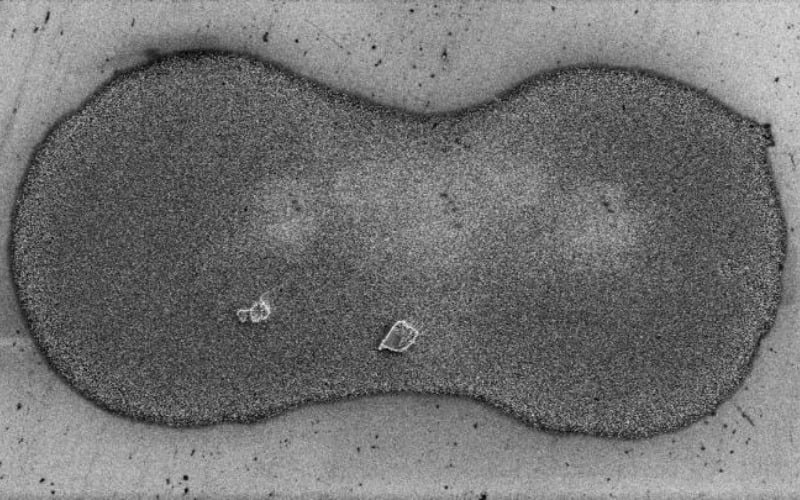

*Cover photo shows a pair of inkjet printed droplets with silver nanoparticles, courtesy of Gustavo Trindade.