Involve Space is Using AM to Make Space More Accessible

Additive manufacturing is used in many industrial sectors, especially those that continually seek innovations in terms of technologies, processes and materials. Chief among them is undoubtedly the aerospace sector, for which R&D is crucial. In this context, the use of additive manufacturing is becoming increasingly widespread, with the aim of achieving higher performance, optimizing final parts and processes. To learn more about the many ways to use 3D printing in this industry, we interviewed Involve Space, an Italian startup whose goal is to make space activities more accessible and environmentally friendly with the use of additive manufacturing.

3DN: Can you introduce yourself and tell us what Involve Space is?

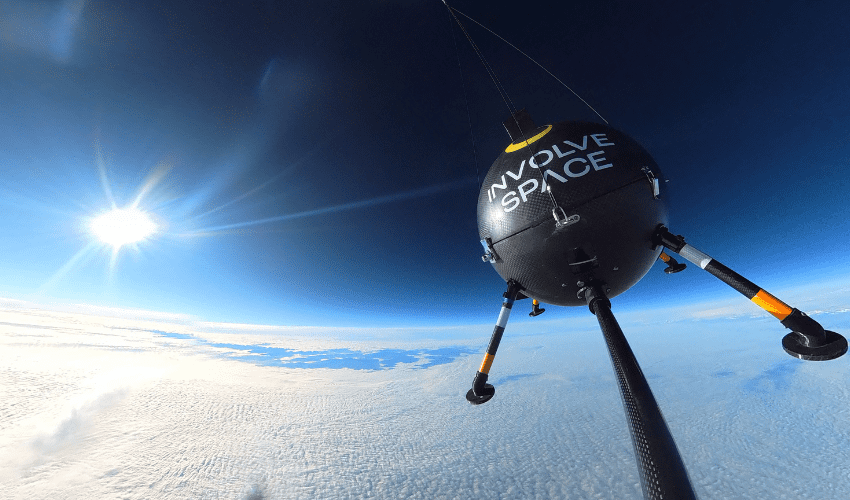

I’m Claudio Piazzai, Director of Operations and Projects at Involve Space. Involve Space is an innovative Italian startup operating in the aerospace sector. We provide launch services in the stratosphere through our pseudo-satellite platform composed of a stratospheric balloon, a probe and a strong integration with an artificial intelligence software component. The missions we perform are varied, but our main market segments include testing (of satellites, materials and electronic devices), earth observation and scientific research (including atmospheric composition analysis).

3DN: When and how was Involve Space born? What is its main mission?

Involve Space’s origins date back to 2015. Jonathan Polotto, CEO of Involve Space, launched a GoPro attached to a “homemade” aerospace probe into the stratosphere with the goal of making a viral YouTube video. Subsequently, there have been several company-level evolutions through stratospheric launches for commercial and marketing purposes. In 2021, Involve Group actually registered as a company. Back then, the infrastructure was very different and more spartan, but over the years we discovered the true potential of these missions and started to focus on what is now the real core business of Involve Space: launches for scientific and technical purposes. Thus was formed the highly specialized team of engineers and developers that, together with a strong commercial and management presence, forms the backbone of the entire company.

3DN: How do you use 3D printing and what advantages have you observed?

3D printing is very important in our business. We are able to design and build our probe in-house thanks to the use of additive manufacturing, which is crucial both in the prototyping phase and in actual production. In fact, most of the components of our current probe have been prototyped and 3D printed.

In addition, it often happens that we need to replace a broken or defective part. This can also be done internally by 3D printing a part identical to the previous one. In addition, for each mission it is necessary to have customized and tailor-made parts to accommodate the equipment. This is possible thanks to 3D printing, which allows us to maintain some flexibility and the ability to adapt our solution to the customer’s needs (keeping everything customizable). Our team can design the parts and print them, doing it all ‘in house’, a great advantage that saves us time and money.

3DN: What 3D printing materials do you use?

We use PLA and PETG for parts that need mechanical strength but at the same time lightness. For example, we created housings for electronics, release system parts, balloon valve parts and other key components for our launch service startup. We also printed in TPU for specific applications that required a more flexible material.

3DN: What does your vision of accessibility and sustainability consist of?

Getting physically close to space has always been considered a privilege for a few, only large corporations and billionaires have had this possibility until now. Involve Space allows even small and medium-sized companies, thanks to its extremely reduced costs, to exploit aerospace technology and perform missions in the stratosphere. In addition, our aerospace launches are fully environmentally sustainable, as both our balloon and our probe are designed to be reused for each launch. And our only propulsion source is Helium gas, which is abundant in nature and non-polluting.

3DN: What are your future plans?

We are working on the development of a launch kit-box, to enter the B2C market, allowing people to perform “amateur” stratospheric launches autonomously. We also want to develop a constellation of stratospheric balloons, capable of performing multi-day missions, which will allow us to enter the telecommunications sector and expand the range and scope of Earth surveillance services. Finally, we plan to further integrate the stratospheric platform with our artificial intelligence software and sell the software and its customizations.

3DN: Any last words for our readers?

Involve Space is constantly working to bring everyone closer to space, making that distant, mysterious, sci-fi world a concrete reality within everyone’s reach. We firmly believe in: “If the why is strong enough, the how will come on its own!” which so far has taken us higher and higher into the stratosphere. And tomorrow who knows, maybe even higher! For more information about Involve Space, visit our official website and, for commercial projects, the Involve Productions website.

What do you think of Involve Space and its stellar objectives? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Involve Space