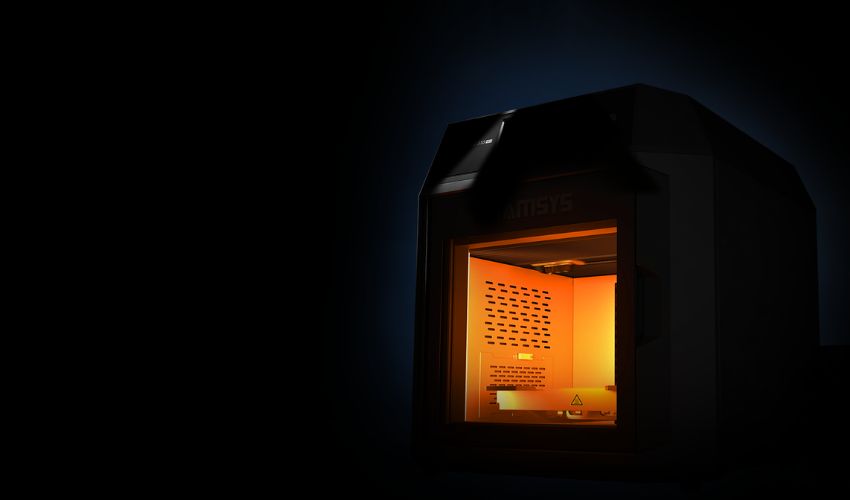

INTAMSYS Unveils FUNMAT PRO 310 NEO, Bringing Superior Industrial 3D Printing in a Desktop Size

Leading 3D printer manufacturer INTAMSYS has made quite a name for itself in recent years. The solutions provider is known for its industrial FFF 3D printing machines which are compatible with high-performance materials like PEEK, PEI, PPSU and engineering materials, among others. Now, INTAMSYS has another to add to that list, the new INTAMSYS FUNMAT PRO 310 NEO 3D printer.

You may already be aware of the original INTAMSYS FUNMAT PRO 310 3D printer. The solution is notable for its many features in a more compact package. And the NEO is an evolution. Building off the idea that the printer will “bring industrial performance to your desktop,” the FUNMAT PRO 310 NEO 3D printer promises to bring user experience to a new level with features that will meet the needs of everything from engineers to designers. Let’s take a closer look at what you can expect.

The INTAMSYS FUNMAT PRO 310 NEO 3D Printer Combines Speed With Quality

According to INTAMSYS, the FUNMAT PRO 310 NEO 3D Printer is classified as a high-speed, industrial FFF 3D printer that has been designed for direct industrial applications and small batch production. This means that it needs to meet stringent requirements for industrial customers who are looking for print precision, material performance, repeatability and consistency, printing efficiency and of course safety. But how has it achieved this?

Well, one of the most notable aspects of the FUNMAT PRO 310 NEO is its high speed, possible due to the printer’s newly developed high-speed architecture. This enables a 50% reduction of printing time, all while still ensuring quality at these high printing speeds. A necessity considering that the maximum acceleration is 10,000 mm/s2 for significantly enhanced production.

Beyond that, the printer also integrates control algorithms as well as optimized material process packages for high-speed printing. Thus, ensuring both superior surface finish and high dimensional precision even with the high printing speed. Currently, there are eight types of material printing process packages for PPA-CF, PPA-GF, PC, PC-FR, PC/PBT, ABS-HS, PA12-CF and PLA. Given that PC especially is notorious for being difficult to print, especially at high speeds, the FUNMAT PRO 310 NEO hopes to fill that industrial need on the market.

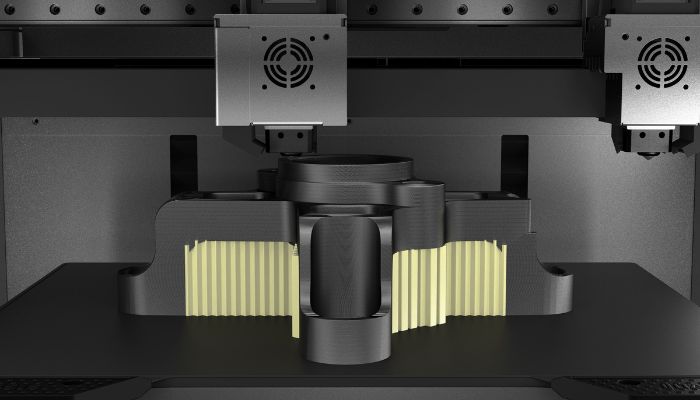

The IDEX printer has been primed for high-speed extrusion without a loss of quality

Additionally, this speed has a clear benefit when it comes to improved production, a necessity with industrial 3D printing. Namely, the production capacity of the machine can reach 500 g to 1000g per day with an average speed of 250mm/s. Of course, the actual production depends on the material used and whether mirror or duplicate mode for the dual extruders is activated. The latter will obviously increase the capabilities of the machine and thus production, reaching 1000g/day, but will bring the build volume down from 305 x 260 x 260mm to 260 x 260 x 260mm. Although this is still a respectable size for a desktop solution.

Features for Engineering-Grade Printing

But while speed is an obvious draw, that is not all that users can expect from the FUNMAT PRO 310 NEO. Like its predecessor, the 3D printer boasts an up-to-100°C thermostatic chamber, which helps to achieve what the manufacturer calls “true engineering plastic full-scale printing capability.”

If you have tried to print with engineering materials before, you know how important it is to have a heated chamber. INTAMSYS has gone even further with this by ensuring the heating will be uniform throughout with a fluctuation range of less than 5%. These will ensure lower internal stress and better interlayer bonding during printing, as well as reducing model shrinkage to avoid warping.

There is also a heated build platform capable of reaching up to 160°C. These combined together not only make it possible to print with a wider range of engineering-grade materials, but also can improve the consistency of the mechanical properties of the resulting prints. INTAMSYS has found that maintaining a consistently high chamber temperature can enhance the interlayer adhesion for benefits like greater tensile strength for ABS and improved mechanical properties for PC and PC-ABS. This makes the printer more consistent as well, ideal for mass production and the manufacturing of end-use parts.

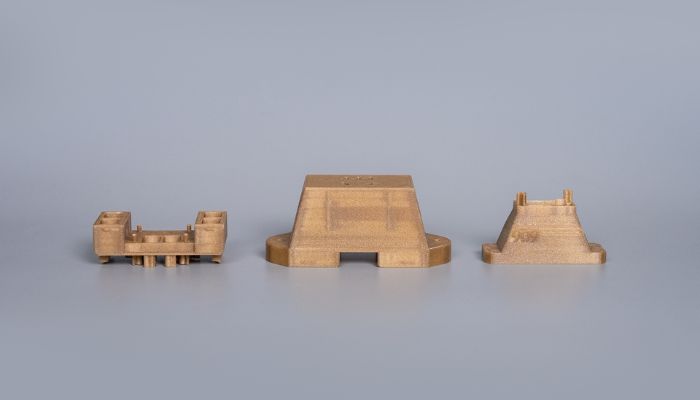

FUNMAT PRO 310 NEO 3D printed parts made using PPS-GF

But the heated chamber is not the only benefit. While many of INTAMSYS’ solutions are compatible with multi-material printing, the FUNMAT PRO 310 NEO also integrates a new 350°C nozzle. It not only ensures a high success rate, according to the manufacturer, but also allows for the printing of high temperature materials like PPS and PPA, which were not previously possible.

More specifically, this versatility means that users can print a wide range of materials (including PC, PC-FR, PC/PBT, PC/ABS, ABS-HS, PA12-CF, ABS+, ASA+, PA6/66, PA6-CF and TPU95A) without changing out the nozzle. INTAMSYS also mentions the printer’s compatibility with PC-FR, which has flame retardant properties for use in sectors like rail transportation, PC-ABS which is ideal for long-term outdoor automotive applications and PC/PBT for electronic manufacturing.

Furthermore, the IDEX system itself is worthy of note thanks to its four working modes (mirror, duplicate, dual, support material printing) and its easy-to-remove, modular design. Support mode printing especially can be useful when used in conjunction with water-soluble/easy-peeling support material solutions for engineering materials. Additionally, as mentioned earlier, modes like mirror and duplicate can increase the productivity of the machine.

The IDEX solution has different modes, including support (pictured above)

Improved User Experience

Clearly, the FUNMAT PRO 310 NEO is suited for industrial applications thanks to its features and material portfolio. But INTAMSYS has also worked to generally improve user experience.

For example, the FUNMAT PRO 310 NEO includes features like IDEX auto z-axis leveling with dual nozzle difference mitigation (ensuring that they will be equal during printing), mesh leveling up to 10 x 10 mode (for real-time compensation and greater accuracy during printing), remote networking capabilities and the INTAM™Box.

This last point is interesting because INTAMSYS claims that by using it, it will be possible to have up to 20 days of continuous high-quality printing. How? Well thanks to the sealed design, materials will not get moist due to low humidity, cutting down drying time for the filaments. This is especially important for ensuring quality while printing with hygroscopic materials like nylon.

All in all, INTAMSYS seems to have done what it could to ensure that the design of the machine will be industrial and robust, allowing for high-intensity continuous production. Although only time will tell how the FUNMAT PRO 310 NEO will perform, it is a promising launch with INTAMSYS once again showing its commitment to industrial-level, extrusion 3D printing with a vast material portfolio and features that will help boost productivity. You can learn more about it HERE.

The INTAMSYS FUNMAT PRO 310 NEO 3D Printer

What do you think of the INTAMSYS FUNMAT PRO 310 NEO 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: INTAMSYS