Ingeo 3D700, The New PLA Grade Biopolymer for Large Format 3D Printing

NatureWorks has developed a brand new PLA-Grade biopolymer which supplies a considerable reduction in warping and minimizes print failures, to add to its Ingeo range. Ingeo 3D700 is particular in that it is designed specifically for large format 3D printing, wherein warpage is a common issue. Monofilaments made with Ingeo biopolymer PLA are known for their precision of detail, impressive adhesion to build plates without heating, reduction of warping, curling and odor as well as other high performance characteristics. The range’s addition of the large format 3D printing option, Ingeo 3D700, thus comes as a natural step.

“As the 3D printing space expands into larger, more complex applications, we are seeing an increased need for printing materials that are tailored for a specific application or process,” says Dan Sawyer, Business Development Leader for NatureWorks. “With significant growth in large-format additive manufacturing for industrial applications, we saw the opportunity to develop a new Ingeo biopolymer grade specifically designed to minimize the loss of time and material due to failures in large format prints.”

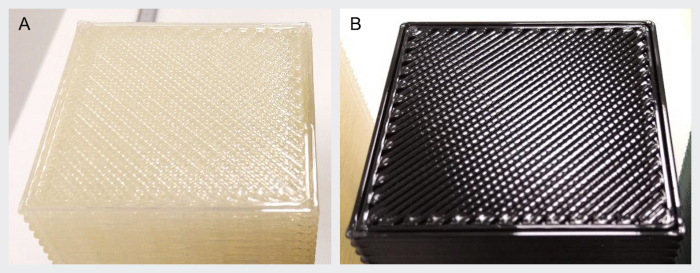

The part (A) printed with clear Ingeo 3D700 shows fewer gaps on the top solid-fill layers and between perimeters in comparison to the general-purpose PLA grade part (B) in black.(Photo Credit: MCPP).

Ingeo 3D700 is designed for large format 3D printing

Large format printing is more susceptible to excessive warpage with materials including ABS due to the higher rate and volume of polymer deposition. This can also cause significant shrinkage with some polyolefins or even general purpose PLA grades. These issues can in turn result in failed prints as parts can get pulled away from the print bed or have its layers separated. In large format printing this can be costly, due to longer print times and higher-volumes. However, thanks to its controlled polymer-microstructure, Ingeo 3D700 has a low material shrink rate, meaning that it is less likely to warp, and instead has improved gap fill and adhesion. This new material, therefore offers a higher probability of successful prints.

Philippe Carrier, CTO at Dyze tested the product: “Our tests showed that a large-format part printed using Ingeo 3D850 demonstrated a shrink rate of 1.25%. In comparison, the same part printed with Ingeo 3D700 had a shrink rate of less than 0.25%.” He continues, “Because Ingeo 3D700 also has a higher throughput rate, we were able to successfully print at the lower temperature of 190ºC without seeing shrinkage or warping in the part.” Another benefit of NatureWorks Ingeo range is its environmentally friendliness, as polylactic acid (PLA) performance materials made from greenhouse gases:

You can find out more about Ingeo 3D700 on NatureWorks website HERE. What do you think about Ingeo 3D700? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!