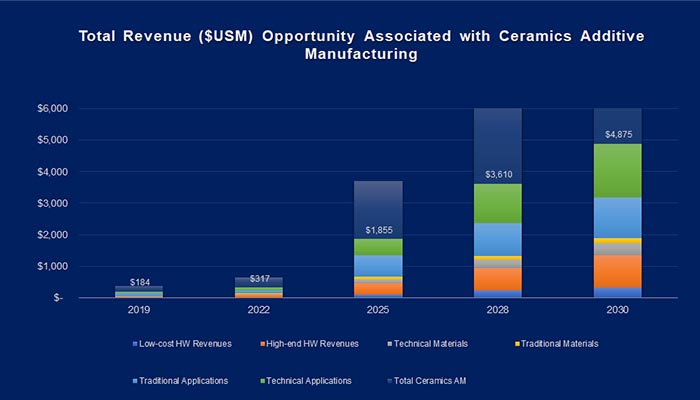

Industrial ceramic AM will grow into $4.8 billion revenue opportunity by 2030

The market research firm SmarTech Analysis has issued a new report on the ceramic 3D printing market – Ceramics Additive Manufacturing Part Production: 2019-2030 – which identifies the most commercially important additive manufacturing technologies, material types and material form factors, as well as application segments for ceramics additive manufacturing, differentiating between technical and traditional ceramic materials. The research firm had already released a report on this segment of additive manufacturing in 2017. Some of its forecasts have been adjusted, however the firm does not believe that COVID-19 will hinder growth by a large margin given its figures.

In the report, SmarTech Analysis expects that despite current disruptions due to COVID-19, the overall ceramics AM industrial sectors, including hardware, materials and application revenues, will grow into a $4.8 billion revenue opportunity by 2030. It had previously predicted that it would generate $3.8 billion by 2028. Final parts value for both technical and traditional ceramic parts will continue to represent the most significant opportunities, driving the market for the medium to long-term future.

Image via SmarTech Analysis

Industrial Ceramic AM is Growing

SmarTech explains that the adoption of ceramic additive manufacturing will jump in 2025 because 3D printing technologies capable of supporting ceramic final part production will finally be mature. By this the firm means that manufacturers will finally be able to use systems for series production instead of prototyping, which will in turn drive market demand and revenue. Moreover, technical ceramics applications are forecasted to grow the most. These ceramics showcase great properties including mechanical, thermal, chemical and electrical resistance – especially useful in sectors such as automotive or aerospace.

“The ceramics AM applications market is expected to triple in size after the inflection point that is expected to occur in 2025, after the market fully recuperates from COVID-19 related slowdown and as ceramics manufacturing companies reap benefits from investments made in hardware and materials development over the previous ten-year period,” you can read in the report. Additionally, it’s expected that the response to the COVID-19 crisis will have an impact on overall geographic distribution of revenues, with the APAC region emerging as the winner for implementing more efficient methods of managing business and manufacturing during the ongoing epidemic. “APAC area nations, China and Japan in particular, are already adopting ceramic AM technologies for production at a faster rate than most European and American nations.”

The report goes into great depth on each factor that contributes to ceramic additive manufacturing such as an analysis of the different types of firms offering ceramic AM services and parts, including specific forecasts on ceramics AM service providers, ceramic 3D printed parts providers and ceramic 3D printed parts adopters. The key ceramics AM industry leaders analyzed in this report include 3DCeram-Sinto, Lithoz, Prodways, Admatec/Formatec, ExOne, voxeljet, SGL Carbon, Schunck Carbon Technologies, XJet, Nanoe, Johnson Mattheys, and a large number of other entities operating in ceramics AM services, cement extrusion as well as ceramics AM end-users.

You can find more information HERE.

What do you think of these predictions by SmarTech Analysis? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!