Industrial AM in the Spotlight at Formnext 2023 With INTAMSYS

Formnext is coming up quickly! And as one of the biggest additive manufacturing events of the year, it will certainly allow many different companies to show their innovations to a wider field. However, with over 800 exhibitors, it can be hard to know who you should see. But one exhibitor who certainly should not be missed at Formnext 2023 is INTAMSYS. The company will be putting a focus on their solutions for industrial 3D printing at their booth this year (Hall 11.1, B31).

INTAMSYS has grown quickly since its origins in 2016, becoming one of the worldwide leaders in industrial 3D printers. Indeed, in May of this year they announced that they had completed series B financing led by CMB International, followed by Forebright Capital and Porsche Ventures, showing the continued viability of and interest garnered in its technology and solutions. Moreover, we have already spoken to you about the company, highlighting their solutions as well as some of their exciting applications. But what exactly can you expect from them at Formnext this year?

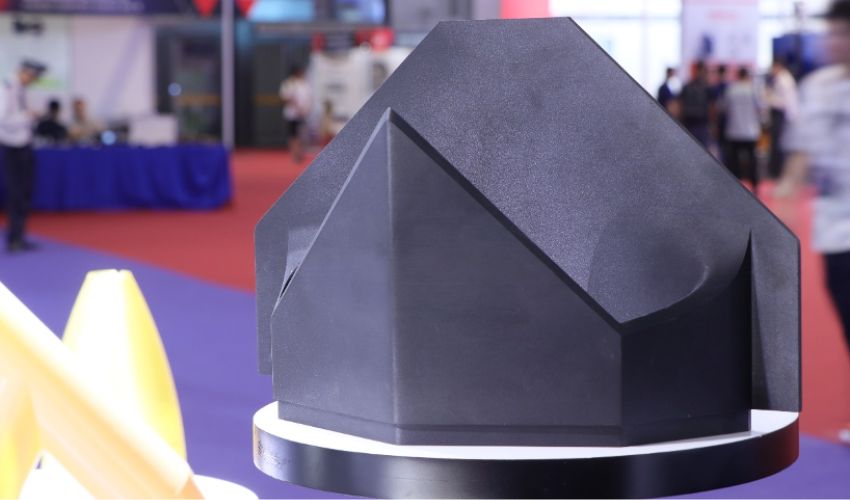

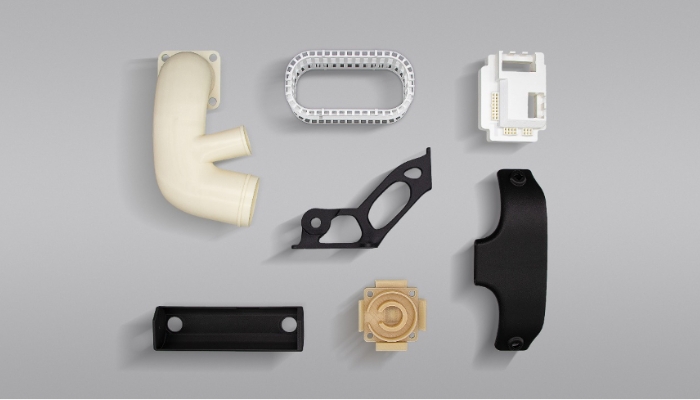

Printed parts made on the FUNMAT PRO 310 (photo credits: INTAMSYS)

INTAMSYS to Focus on Industrial 3D Printers at Formnext 2023

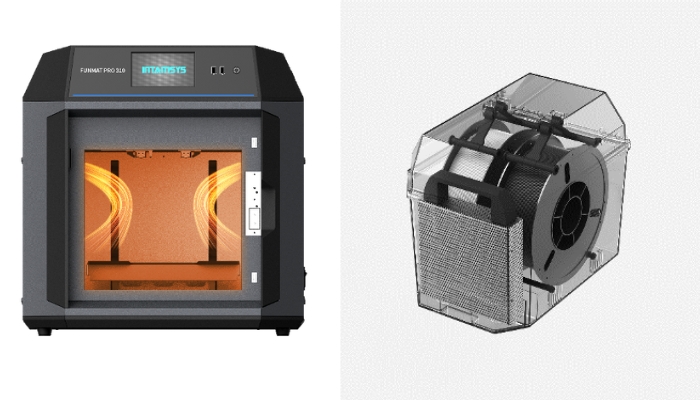

One of the main draws of INTAMSYS at Formnext 2023 will be their FFF industrial 3D printers. Most of the company’s portfolio will be present at the event, but we want to focus on two. These are the FUNMAT PRO 610HT and FUNMAT PRO 310 which, while not necessarily new-to-market, continue to reign supreme as two of the company’s flagship printers along with the FUNMAT PRO 410. In particular, the FUNMAT PRO 310, launched in 2022, has some interesting features that could be a draw for many at the event. Notably, the printer has been designed to “bring industrial 3D printing to the desktop” with its compact but still impressive size of 700x655x700mm. The FFF 3D printer has quick change printheads as well as IDEX technology with a max printing volume of 305x260x260mm.

To enable printing with engineering materials, the printer also includes a 100°C fully-enclosed build chamber. This heated chamber is particularly crucial as it can reduce thermal deformation shrinkage of the model during the printing process, allowing users to avoid warping. As well as allowing users to take advantage of the full dimensions of the large-format 3D printing. This plays an especially important role depending on material, for example PC which is significantly affected by temperature during the printing process.

The 100°C fully-enclosed build chamber of the FUNMAT PRO 310 (left) and the independent filament box of the INTAMSYS FUNMAT PRO 310 (right)(photo credits: INTAMSYS)

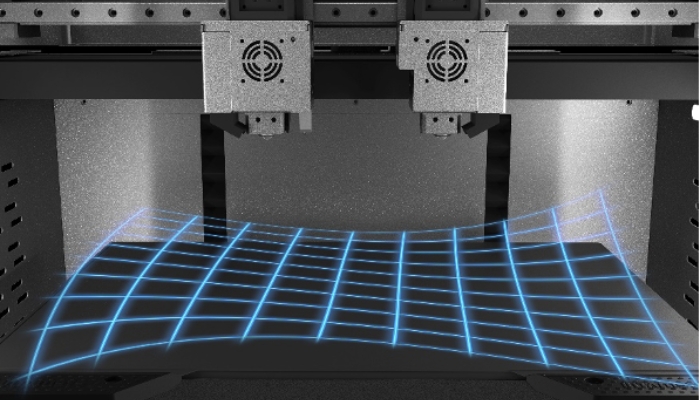

Other features that also support more professional 3D printing include mesh-leveling with multipoint calibration on the build plate, an intuitive interface for users with INTAMTOUCH and a HEPA filter + active carbon. Additionally, users can take advantage of remote surveillance, remote control and remote printing. The high-power nozzles also decrease heating time ensuring full melting while also actively cooling the cold end of the printhead to reduce the risk of clogging.

Not only that, but the FUNMAT PRO 310 also comes with its own independent filament box, the INTAM™ Box. This has a sealed design with molecular sieve dehumidification as well as a built-in temperature and humidity monitoring sensor, ensuring that filaments will stay dry. A factor that is especially important when you consider that engineering filaments have much higher requirements when it comes to dryness. This box will ensure dry filament for weeks and thus improve printing quality in the long term. Other accessories like INTAM™ Oven, which can be used for drying and annealing, are also available from the company and should be shown at the booth.

Mesh-leveling with multipoint calibration (photo credits: INTAMSYS)

Furthermore, INTAMSYS will be showing one of its most popular offerings, the long-standing FUNMAT 610HT at Formnext 2023. This FFF 3D printer is a mainstay for the company thanks to its reliability and efficiency. The printer is known for its large-format, high-temperature and industrial production with a 300°C heated chamber which has even been confirmed by outside sources to show its efficacy and uniformity of chamber temperature. This includes findings from national authorities showing that under a chamber temperature of 300℃, the temperature range of each position in the printing area is ±7.5℃. Perhaps another reason the FUNMAT 610HT has been so popular, particularly among service bureaus as well as those who need continuous production.

The Launch of INTAMSUITE NEO

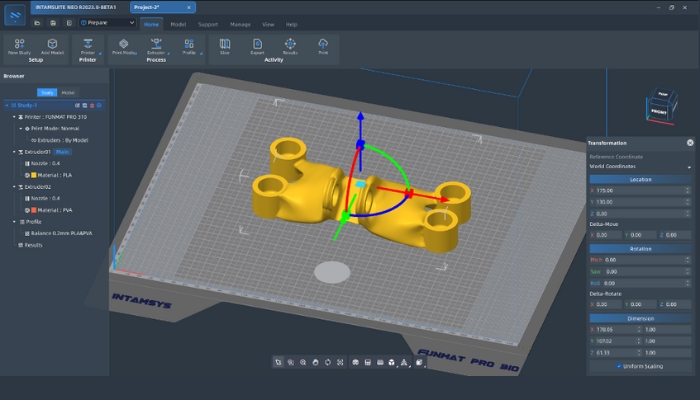

Although INTAMSYS is well-known for its industrial 3D printing solutions, this year the company has also been turning a focus towards software to complement their hardware. This includes INTAMSYS HUB, a new cloud printing platform management software as well as INTAMSUITE NEO, a new slicing software. INTAMSUITE NEO aims to help users to overcome common obstacles when it comes to 3D printing workflow. Launched in mid-October, this completely free software will take the guesswork out of slicing once and for all. This will be done in several different ways. Notably, it will integrate a “ribbon-style” UI that is reminiscent of CAD-style software, according to a press release from the company. This will provide a sense of familiarity and therefore reduce the learning curve as well as allowing for an easy at-a-glance overview of all necessary information.

A ‘ribbon-style’ UI provides offers users an easy overview of print settings (photo credits: INTAMSYS)

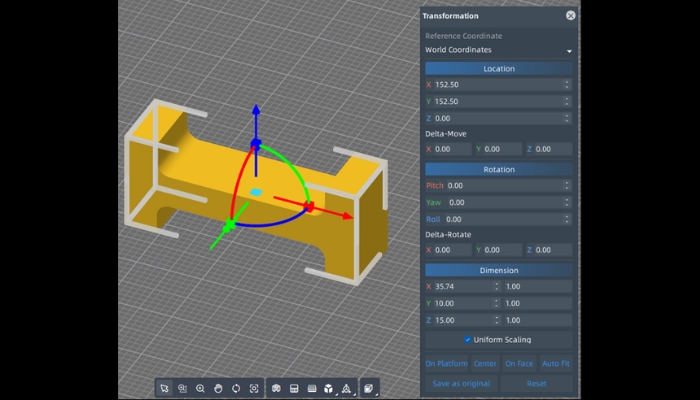

This usability is further enhanced with an “all-in-one” model transformation feature to easily move, rotate and scale models. Printing is easy as well, thanks to built-in print profiles that enable one-click slicing. Support material is also automatically recommended for the part depending on material type and needed adaptations based on thin-wall and finely featured parts. In any case, all the features are focused on ease for the user, a critical component for industrial printing at scale and will be on display as well at Formnext 2023.

If you are interested in learning more about the company, visitors to INTAMSYS’ booth will be able to meet with the developers of the FUNMAT series and new slicing software. It will also be possible to find a wide variety of customer parts as well as a surprising application from the automotive industry. Finally, attendees will also be able to benefit from stage talks at the booth. Visitors can follow INTAMSYS’ social media channels for the daily agenda at Formnext 2023.

An ‘all-in-one’ model transformation feature enables users to easily move, rotate, and scale models (photo credits: INTAMSYS)

Will you be seeing INTAMSYS at Formnext 2023 this year? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Image: UAV inlet lip used in Aerospace and defense, PEEK-CF, 450x164x287 mm, printed on the FUNMAT 610HT (photo credits: INTAMSYS)