The ESA Bets on Additive Manufacturing in Space With New IMPERIAL 3D Printer

The intersection of 3D printing and aerospace is highly pronounced, especially within the realm of space exploration. NASA and ESA have actively embraced 3D printing for various projects in space, marking a significant shift from traditional methods. Notably, the European Space Agency (ESA) has displayed a long-standing interest in additive manufacturing, dating back several years.

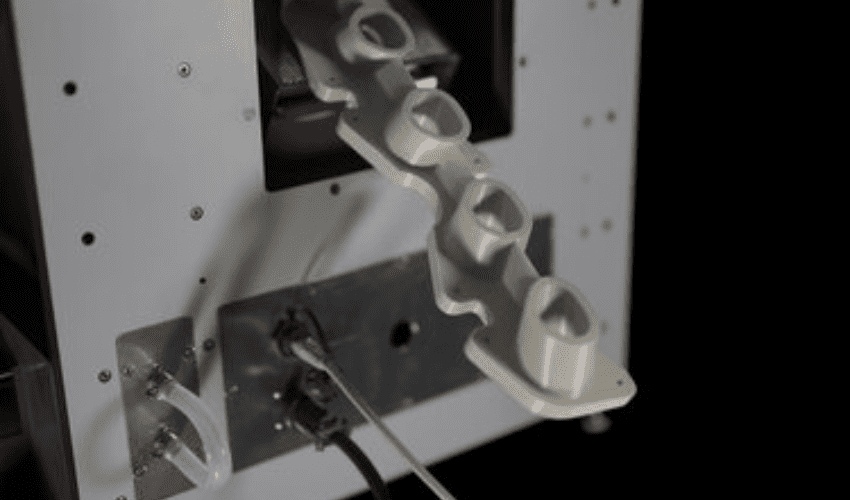

The IMPERIAL 3D printer serves as a perfect example. Developed through a collaboration between OHB System AG, Azimut Space, Athlone Institute of Technology, and BEEVERYCREATIVE, this machine is uniquely tailored to produce parts larger than its available volume. This innovation will enable the manufacturing of structures, tools, and spare parts, crucial for future extended space missions. The primary objective of the IMPERIAL is to streamline operations for astronauts, ensuring swift and efficient access to essential components throughout their missions.

The IMPERIAL 3D Printer in Zero-Gravity

The IMPERIAL printer has been specially designed to meet the manufacturing requirements of the International Space Station (ISS) while surpassing the current limitations of 3D printers. Its strength lies in its ability to print continuously in microgravity conditions, such as a near-zero gravity environment.

To ensure uninterrupted printing of large parts, the IMPERIAL features an ingenious innovation, though one we have seen before: a printing plate in the form of a conveyor belt. This device moves the print along a single axis, enabling continuous production of parts, eliminating traditional constraints and expanding the possibilities of additive manufacturing in a spatial context.

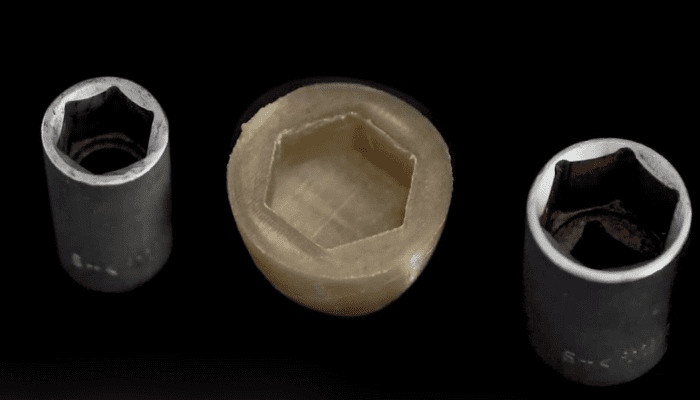

Francesco Caltavituro, a space and systems engineer at OHB who worked on the project, explains, “We are able to print functional parts, especially tools, and interface them with counterparts already onboard the ISS, we can process different materials, such as electrically conductive polymers for small CubeSat components and enclosing or the structure of very large items, such as telescopes. Now we can print anything which needs to withstand the harsh environment of space.”

Designed to operate in zero gravity, the printer also excels at printing parts in high performance polymers such as PEEK, while maintaining quality comparable to that obtained on Earth. “It can all be printed, especially if you want to use high-performance thermoplastics (PEI, PEEK and PEKK), this printer can handle them,” Caltavituro added. To leverage materials selected for their superior mechanical and thermal properties, a system was introduced to uphold a consistent temperature both inside and outside the machine, encompassing the conveyor belt mechanism. Equipped with a heating plate, the machine promotes uniform printing, mitigating the risk of part shrinkage or deformation throughout the printing process.

Having successfully created the prototype on Earth, the next step is to test the IMPERIAL printer in the microgravity environment of the International Space Station (ISS) or on similar platforms, such as ESA’s Space Rider. Although the technology is currently ready for these tests, no precise test date has been determined. To learn more about IMPERIAL, click here.

What do you think of the IMPERIAL? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: The European Space Agency