The impact of 3D printing on supply chains

Today, many industries are hugely reliant on production and supplies from China and Southeast Asia, particularly in sectors like manufacturing and logistics. During the global health pandemic, broken supply chains affected the activities of companies in many industrial sectors. More than 94% of FORTUNE 1000 companies reported that the crisis was having a major impact on their supply chain. Therefore, the pandemic highlighted the limitations of traditional methods, in particular their lack of agility.

Can 3D printing technologies add flexibility to current supply chains?

During the first few months of the pandemic, one sector whose importance emerged was 3D printing. This was especially visible in the medical sector, where it was employed to manufacture emergency equipment for medical staff and patients from all over the world. In a matter of days, actors in the 3D printing sector managed to produce critical devices for the healthcare sector, from masks to ventilators, to help save lives.

In the medical sector, 3D printing was used to produce face shields urgently to protect healthcare professionals

But behind the scenes, manufacturers from all types of industries were suffering from the limitations of current supply chains too. In particular because of the lack of local manufacturing and extended lead times. So, can looking toward 3D printing be part of the solution?

One of the great benefits of additive manufacturing is the portable nature of the technology. It enables businesses to take production to local markets and customers faster. Instead of favouring mass production in other countries, manufacturers could favour more local assembly hubs. Other advantages include greater product customisation, reduced complexity and improved time-to-market. For example, imagine a supply chain where the customer would be more involved in the design and production processes (since the price per unit of a part does not shift). Essentially, each part can be personalised for a customer without carrying that extra cost of customisation.

Additionally, additive is a much quicker method of production. By consolidating the components and processes required for manufacturing, it’s possible to decrease complexities, production costs, and subsequently reduce lead times and time-to-market. Whereas traditional parts need a mould to exist, 3D printed parts only need a digital file to exist. Moreover, moving to on-demand production could become the norm. Which would mean that the need to transport physical goods across countries and continents would reduce, having major impacts on warehousing and logistics.

Manufacturers are able to favour more local production thanks to AM

Nevertheless, for some parts that need to be produced at a very large scale, conventional manufacturing processes like injection moulding or CNC machining will always be more competitive. Therefore, additive has the opportunity of optimizing current supply chains and closing some of the gaps that exist today, but not to replace conventional methods.

How do manufacturers adopt 3D printing?

Many companies have not integrated 3D printers in their supply chains yet. For a long time, barriers to entry have included the lack of know-how and initial investment in the equipment. Which partly explains why 3D printing service providers have grown in recent years. In 2017, Research and Markets predicted in their “3D Printing Services Market – Global Outlook and Forecast 2017 – 2022” that the market would cross $13 billion, growing at a CAGR of more than 28% during 2016-2022. These service providers are able to overcome the barriers companies face in the early stages of integration, when they have not figured out how they will invest in 3D printing for the long term.

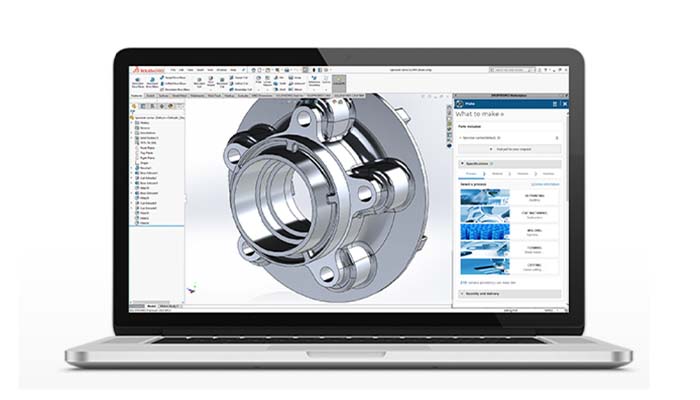

Many solutions have emerged more recently to facilitate this adoption of 3D printing, including getting in touch with providers. For example, Dassault Systèmes’ Make service, part of the 3DEXPERIENCE Marketplace, connects buyers to over 200 manufacturers in Europe and the United States, offering 3D printing, CNC machining, cutting, injection moulding, and other technologies. Benoît Schildknecht, Marketplace Director at Dassault Systèmes comments: ‘The on-demand manufacturing solution by Dassault Systèmes, 3DEXPERIENCE Marketplace Make, allows you to rebuild a more flexible supply chain, safely and closer to you, in order to meet your long-term and short-term needs.’

Solutions have emerged such as Dassault Systèmes’ Make service to facilitate the adoption of 3D printing

It’s also interesting to note that Dassault Systèmes has taken into account some of the typical worries of using such a service. This is why the 3DEXPERIENCE Marketplace allows a buyer to monitor the status of their transaction and keep all of its traceability. Benoît Schildknecht adds, ‘Members can communicate among themselves and compare prices across all available on-demand manufacturing resources thanks to our instant quoting engine. Payment is facilitated, leaving project teams to only worry about the proper execution of the project rather than administrative tasks.’

To conclude, COVID-19 has pushed companies to rethink and transform their supply chains, especially those that have a high dependence on other countries. Reshoring production will allow more flexibility, lower prices and better part quality in many cases. It will be interesting to see how companies go about doing this. In the meantime, you can find much more information on Dassault Systèmes’ on-demand manufacturing service 3DEXPERIENCE Marketplace Make HERE!

What do you think the impacts on global supply chains from 3D printing to be? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!