ideaMaker: The Free Slicer from Raise3D

As you probably know, slicers are a critical step when 3D printing a part. As an intermediary between the 3D model and the 3D printer, slicers allow the machine to understand the information in the 3D model thanks to a G-Code. And depending on the manufacturer of 3D solutions, the solutions differ. Raise3D, one of the historical players in FFF additive manufacturing, offers the ideaMaker slicer. Optimized for all of the company’s 3D printers, it can also work with machines from other manufacturers. Indeed, the software is intended to be easy to use and within anyone’s abilities.

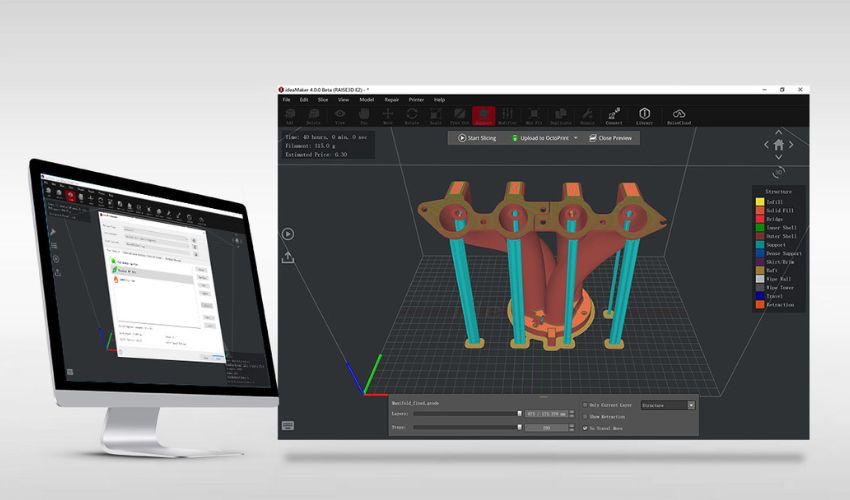

Known for its speed and intuitive interface, ideaMaker is now compatible with most 3D printers using FDM technology. The software allows you to design parts with different surfaces and textures free of charge. Another advantage is a reasonable estimation of the printing time. Once the other parameters are configured, ideaMaker displays the time the printing will last and the quantity of material used. All these options make ideaMaker one of the most popular slicers for FDM/FFF users.

The Slicer’s Various Features

While the support structures are generated automatically, Raise3D explains that users of the software can modify, add, or remove these same support structures with just two clicks. In addition, because of the various print profiles already built into ideaMaker, users can start the manufacturing process quickly. These profiles (high quality, standard, speed) can easily be duplicated and modified by users according to dozens of different parameters.

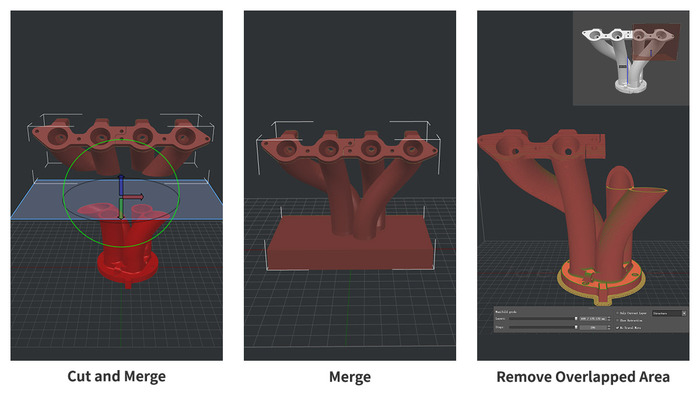

Raise3D also specifies that ideaMaker integrates algorithms to facilitate the calculation of the best cutting parameters. This optimization, which can be activated with a single click, is logically intended to simplify the printing process and avoid users needing to inspect and choose the various parameters manually. The software also offers the possibility of separating an STL file into several parts and printing only a part of it. Another essential feature is model repair. Raise3D’s solution can detect if the file to be printed has a problem, such as a hole, and repair it automatically. Finally, like more and more 3D software, ideaMaker can network multiple 3D printers via WiFi. In this way, it is possible to monitor several printing processes simultaneously.

The ideaMaker Library

To make the printing process as easy as possible, Raise3D has also developed the ideaMaker Library. Here, users of the technology can share and download numerous slicing files ideally suited for different materials and 3D printers. While many of the slicing templates are designed for Raise3D solutions, many other files are compatible with all types of FDM machines. This is a way for the company to encourage users of the technology to share their know-how and increase their productivity.

The RaiseCloud Ecosystem

One of Raise3D’s new products is its centralized 3D printing project manager, RaiseCloud. This platform is designed as a solution for both businesses and independent users, offering the ability to manage an unlimited number of users, 3D printers and print jobs. Users can easily control their workflow, monitor data and adjust settings remotely with just a few clicks. The app can be downloaded from the official Raise3D website or from Google Play and the Apple App Store.

The latest version, ideaMaker 5.0.5, introduces new features specifically designed for resin 3D printing and some additions for printing with filaments. This update includes all the features of the previous versions, ideaMaker 4.3 and 4.4. It is compatible with Windows, macOS, and Linux operating systems and is available in several different languages.

As you can see, with its ease of use, pre-configured parameters, and the ideaMaker Library, the Raise3D slicer has everything to simplify and democratize additive manufacturing. Edward Feng, CEO of Raise3D, puts it, “We continue to work towards the goal of offering an all-in-one solution that increases productivity. With the ideaMaker Library as a valuable new ally, the combination of ideaMaker and RaiseCloud, we are happy to now be able to offer this complete solution and a smooth workflow that will be a game changer for the manufacturing industry.”

What do you think of Raise3D’s ideaMaker? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.