Hyperion Robotics on AM in the construction sector, 3D printing schools in Madagascar, and more

The construction sector has been exploring the potential of additive manufacturing for the past several years. Today, the idea of a 3D printed house does not shock people anymore, as we have seen more than one 3D printed building by now. An increasingly growing number of companies decide to adopt AM for construction purposes. One such company is a Finland-based startup, Hyperion Robotics. Founded in 2019, Hyperion Robotics appeared in international news in summer 2020, when they partnered with an American non-profit organization for an interesting project – 3D printing schools in Madagascar to make education more accessible for the developing African nation. We were curious to learn more about the company that is going to do the actual printing of the schools, so we discussed with Hyperion Robotics’ Chief Design Officer, Dr. Ashish Mohite.

Can you introduce yourself and Hyperion Robotics?

My name is Ashish Mohite, I’m an architect and PhD researcher at Aalto University in Finland and I have been doing research in 3D printing for the past 9 years. I’m the co-founder and Chief Design Officer of Hyperion Robotics, where we are bringing automation, robotics and 3D printing technology to make the construction industry more efficient and sustainable. The company was officially launched in Finland in 2019 when I joined my co-founder Fernando De los Rios (Hyperion’s CEO), bringing my vast experience in 3D printing and architecture, to solve a problem that I’ve suffered myself in home building and construction projects in India and in Europe, and to try to make a significant impact in the least automated industry in the world.

My name is Ashish Mohite, I’m an architect and PhD researcher at Aalto University in Finland and I have been doing research in 3D printing for the past 9 years. I’m the co-founder and Chief Design Officer of Hyperion Robotics, where we are bringing automation, robotics and 3D printing technology to make the construction industry more efficient and sustainable. The company was officially launched in Finland in 2019 when I joined my co-founder Fernando De los Rios (Hyperion’s CEO), bringing my vast experience in 3D printing and architecture, to solve a problem that I’ve suffered myself in home building and construction projects in India and in Europe, and to try to make a significant impact in the least automated industry in the world.

What 3D printing technologies does Hyperion Robotics use?

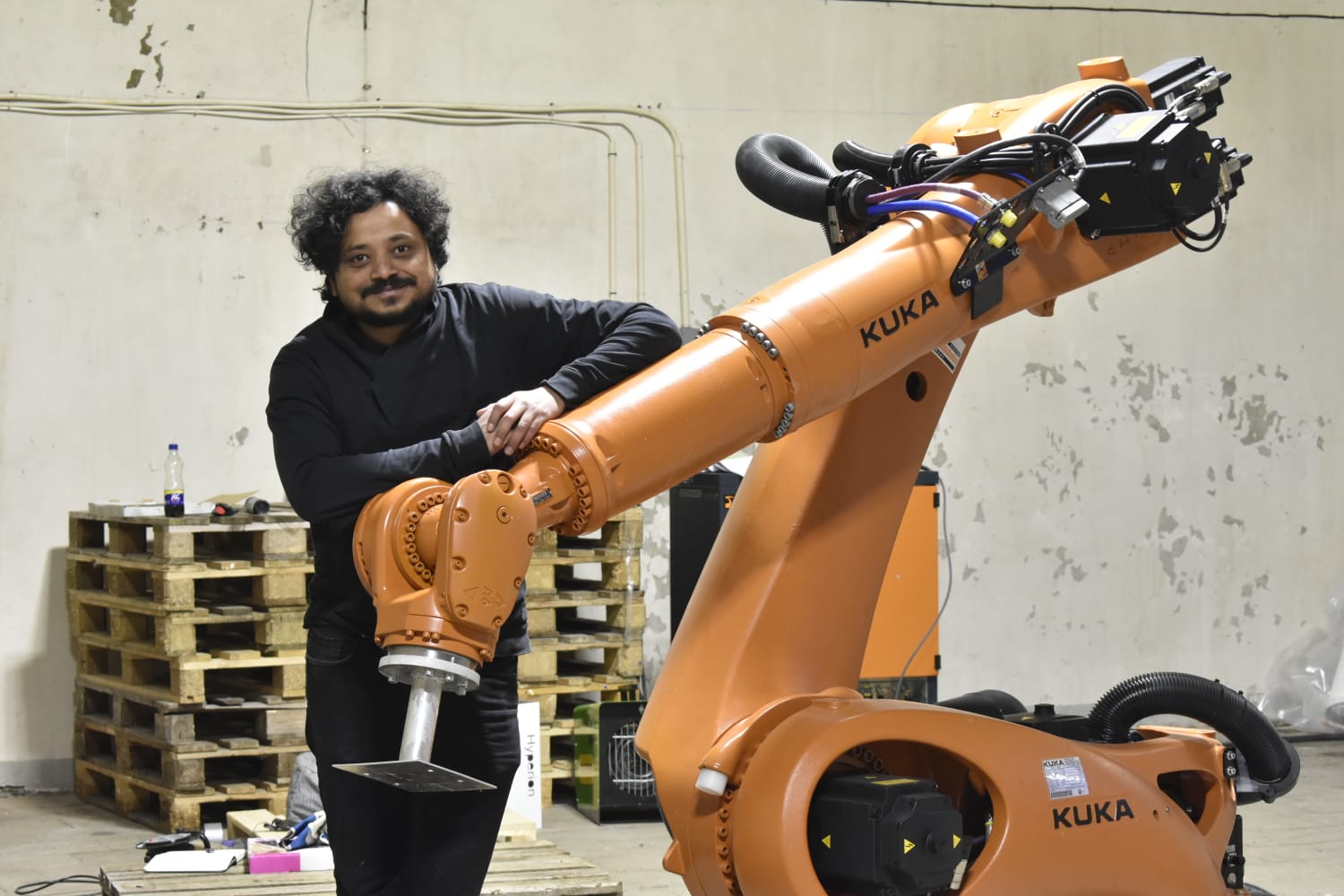

Our 3D printing system is based on industrial robotic arms. We are currently using Kuka robots in our projects, but we are “robot agnostic” so we are also able to integrate our proprietary software – which can be used by anybody with no technical background – and 3D printing equipment in different kinds of systems. From the materials side, we use a special mix of concrete which uses a reduced amount of cement thanks to recycled waste components and is optimized for different applications and environments. We are working with our industrial partners to develop more sustainable and high performance mixes for 3D printing. We also have a very special method to incorporate reinforcement in the process. We offer our technology as an end to end solution to our customers, just the way construction companies and developers are used to working with subcontractors, and we are able to adapt our offer depending on their needs.

What kind of projects have you been involved in so far?

We always try to get involved in very interesting projects. To give you a couple of examples, we just finished the Create Summer School in concrete 3D printing with our academic partner the CREATE Group from the Southern Denmark University in Odense where we run 3D printing workshops and concrete experiments with many students with different backgrounds. This is one of the first projects with CREATE, which is led by professor Roberto Naboni, where we are looking to push the boundaries of 3D printing in the built environment and also to find ways to reduce the industry’s significant carbon footprint, taking advantage of the state of the art testing facilities at the University. Another very interesting project is with Thinking Huts, an American NGO that plans to 3D print schools for countries in Africa where there is almost no access to education for the majority of the child population.

3D printed prototypes of artificial reefs. (Image credits: Hyperion Robotics)

Can you tell us more about the Thinking Huts project?

The Thinking Huts project is one we are very enthusiastic about because it combines innovation, sustainability and a large social impact aspect. Children in Madagascar and Africa have a lot of limitations in terms of access to education so we have decided to join forces with Maggie Grout and the team at Thinking Huts as their technology partner. We are providing our robotic systems and know-how in 3D printing and construction to be able to build the first school in Madagascar. Once this project is successfully built (we are very confident about it), it will be the steppingstone to help Thinking Huts get closer to their mission to increase global access to education. We envision that after that, we will be deploying more robots and help them build schools on a larger scale, tens of thousands of kids.

An illustration of a 3D printed school in Madagascar for The Thinking Huts project.

What are the future developments of Hyperion Robotics?

We envision a future where construction sites will be fully automated by robots and we want to be the force that drives this revolution. We are currently deploying 3D printing systems globally, so our immediate goal is to provide our existing clients with the best experience and support, solidify these relationships and be able to leverage those successful partnerships to reach new markets and attract new customers who are convinced that architecture and the construction industry need to change and who want to make an impact in the world. We also have very incredible projects on our pipeline that will be announced very soon.

What is your opinion on the current state of 3D printing in construction & architecture?

We are very excited about the way the construction 3D printing industry is evolving and growing. As we know, the concept of construction 3D printing has been out there for a couple of decades and like most new technologies, has taken quite some time to mature. But we are seeing some exponential changes where large-scale projects are being built, such as low-income housing and infrastructure, and what are known as old and conservative companies, are starting to realize that there is a need for change and are starting to pour tens of millions of euros to be part of this wave. We hope the interest and growth continue and that we start seeing new types of projects, materials and applications around the world.

Concrete 3D printing result up close.

Any last words for our readers?

We are on a mission to make the construction industry more sustainable and automated, and to accomplish this, we need the contribution of all the parties involved, from industrial and academic players to individuals and governments around the world. We are always looking for people, companies and institutions who are passionate about the way technology (such as 3D printing and robotics) influences the way we build so please get in touch via THIS LINK if you want to learn more about concrete 3D printing, start a project with our robotic technology or partner with us to revolutionize architecture and construction. Also, stay tuned and follow our new developments and exciting projects on our website and social media.

A Kuka industrial robot 3D printing a large concrete piece.

You can find out more about Hyperion Robotics and their projects on their official website, HERE. What do you think about this AM construction startup? Let us know in a comment down below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!