3D printing system uses hybrid living materials to make biomedical tools

Hybrid Living Materials (HLMs) are formed by combining living and non-living components such that the resulting composite takes on the properties of both. At MIT’s Media Lab Mediated Matter group, researchers have been studying how 3D printing technologies can control the behaviour of these hybrid materials. More precisely, they hope that controlling the behaviour of the live bacteria inside the HLMs could someday enable medical devices with therapeutic agents built in.

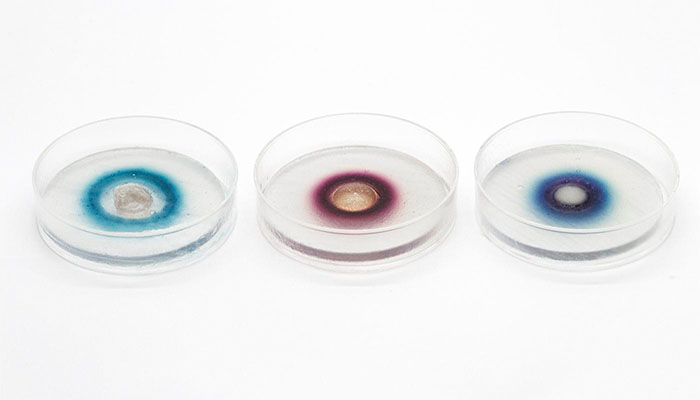

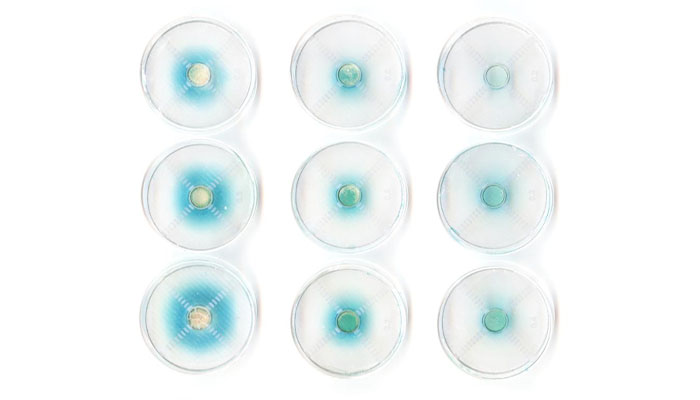

The new development was led by MIT Media Lab Associate Professor Neri Oxman and graduate students. During experiments, a layer containing living engineered bacteria was coated onto the object being 3D printed. Additionally, the team incorporated various chemicals into the 3D printing process, which acted as signals for the biologically engineered bacteria (the team used genetically modified E. coli bacteria). They were able to observe that the bacteria was responding to the chemicals as it changed colour and fluorescence in certain areas. They repeated this process a few times and noticed the appearance of colored patterns in a variety of 3D printed objects, realizing quickly that cells had successfully been incorporated into the surface of the 3D printed materials as they were responding to the chemicals!

Patterns appeared in a variety of 3D printed objects where the HLMs had been placed | Credits: The Mediated Matter group

3D printing Hybrid Living Materials

Naturally, the team had to produce their HLMs. To do so, they invested in a commercially available multimaterial Binder Jetting 3D printer and customized combinations of resins and chemical signals which they used for 3D printing. Once they had the custom resin, they added the living layer, which consisted of a surface coating of hydrogel infused with biologically engineered bacteria. The living layer was spray-coated onto the object. Rachel Soo Hoo Smith, one of the graduate students working on the project explains: “We can define very specific shapes and distributions of the hybrid living materials and the biosynthesized products, whether they be colors or therapeutic agents, within the printed shapes.” Once sprayed the colours took a few hours to develop, the time for bacteria to grow.

These results point to very promising applications, especially for the medical sector. This printing platform allowed material properties to vary within the same object, with some sections stiffer and others flexible, some more absorbent and others liquid-repellent – the resulting variations could be very useful for medical devices! For example, the team explained that biomedical devices designed in this way could provide strength and support while also being soft and pliable to provide comfort in places where they are in contact with the body.

The team was able to define very specific shapes and distributions of the hybrid living materials | Credits: The Mediated Matter group

“In the future, the pigments included in the masks can be replaced with useful chemical substances for human augmentation such as vitamins, antibodies or antimicrobial drugs,” Neri Oxman concluded. You can find out more about this research HERE.

What do you think of this study? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!