HP Presents New Solutions For Process Optimization, Cost Efficiency and Sustainability at Formnext 2024

HP is known for innovative systems and solutions that support users at every stage of their 3D printing journey. This is thanks to a commitment to cost reduction, automation, efficiency, quality and sustainability, values that are also reflected in the new innovations that HP is presenting at Formnext 2024, currently taking place. But what exactly does HP have in store at the event this year?

Starting Small, Growing Together Consistently

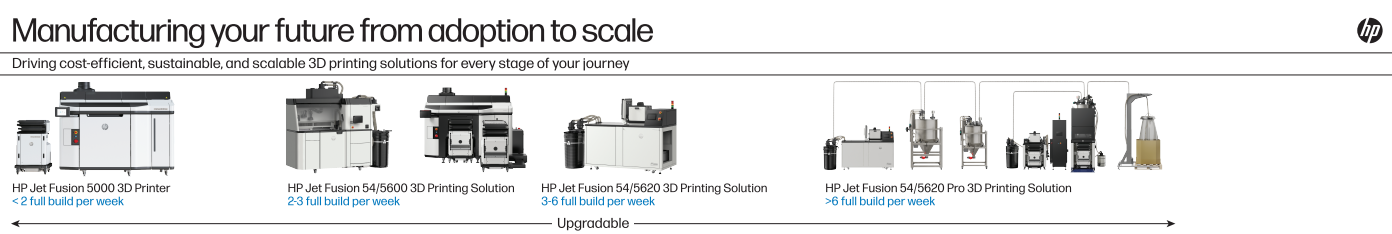

In recent years, with the increasing industrialization of additive manufacturing, we have seen a growing demand for automation, process optimization and scalable systems. HP is addressing these needs by adapting the hardware it offers for printing polymers and metals. For instance, aligning with the continued growth of polymer additive manufacturing, HP has reacted with a fully upgradeable portfolio allowing clients to go from the HP Jet Fusion 5000 to the 54/5620.

For those who prefer to start their 3D printing journey small and grow their productivity in parallel to their demand growth, the HP Jet Fusion 5000 system offers the same quality MJF components at a fraction of the acquisition cost of HP’s more advanced production systems such as 5400/5600 series solutions. The main benefit is that HP’s systems are designed with upgradeability in mind. So, when the user reaches production capacity with their 5000 systems, they can easily expand their productivity by making a few additions to their existing system to upgrade to the 5400/5600 series production systems, without requiring any hardware change to their existing 5000 system.

And for those who are already at high production scenarios more suitable for the 5400/5600 series systems, HP invests in continuous improvement of the production systems by delivering automation solutions and optimization of the existing systems both from a digital and physical perspective. Many users of these systems today leverage the software and system improvements to optimize the OEE (overall equipment effectiveness) of their equipment to increase production capacity or further reduce their operational costs.

Part produced on the HP Metal Jet S100 (Credits: INDO-MIM)

Expanded options for metal 3D printing systems are also present by HP at Formnext 2024. New configurations have been designed to increase the process efficiency of the HP Metal Jet S100 platform, extending its high quality, repeatability, speed and reliability to a wide range of production requirements. This should allow users to move seamlessly from one production scale to the next using a single consistent platform.

Cost-Optimization Through Innovative Software

In addition to the innovations for scalability and process efficiency in hardware, HP is also working to improve software, focusing primarily on cost optimization. First, HP is continuing its work with Autodesk to fully integrate build preparation software with HP’s Multi Jet Fusion and Metal Jet technologies, helping to optimize build costs and quality. Additionally, HP is offering the new HP 3D Build Optimizer, a software tool designed to automatically re-nest parts to reduce builds costs while maintaining part quality.

Expanding Into New Markets

Always looking for innovative opportunities to benefit its users, HP is now expanding its offering with a flame-retardant material, PA12FR enabled by Evonik. For industrial electronics, consumer goods electronics, medical devices and electric vehicle manufacturers that are subject to strict safety regulations but still require quality components with high performance, this new flame-retardant material is a game changer. As a halogen-free FR material with 50% reusability, this material becomes a cost-conscious alternative to other flame-retardant materials in traditional manufacturing like injection molding or CNC machining, but also additive manufacturing.

Companies like Bronymec who have extensive expertise in electronics industry have already adopted this material, providing various electronic housings, battery holders, cable covers and medical device casings to their clients, ensuring safety of these components without sacrificing performance. Protolabs is another user who provides smooth-surface PA12FR components to their clients, leveraging the fact the material is manufactured using renewable energy sources and reduced carbon footprint. This contributes to the end-users’ sustainability and carbon footprint goals with this material, while capitalizing on general 3D printing benefits like lightweighting or complex designs with lattices that further reduces material waste and carbon footprint.

PA12FR enabled by Evonik is halogen-free, flame-retardant and has a high reusability rate (photo credits: HP)

If you would like to find out more about HP’s solutions, you should definitely stop by the HP stand at Formnext. Located at booth D41 in hall 12.1, visitors will be able to discover innovations and numerous application cases. You can find out more HERE.

Will you be visiting HP at Formnext 2024? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Picture: Racing car – battery cooling housing printed with HP JF 4200 3D and HP 3D HR PA 12 GB – Courtesy of ETSEIB Motorsport