How to Properly Store Filaments for 3D Printing

FDM/FFF 3D printing is becoming increasingly popular, especially for private use. Whether at home or in the office, 3D printing with filaments can not only be a handy way to create everyday objects, it also gives free rein to creativity and is fun and enjoyable for everyone – young and old! But that does not mean that there are not challenges. This includes proper filament storage.

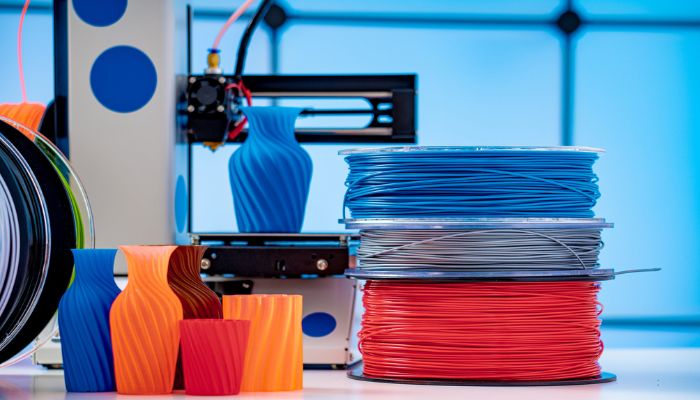

The selection of filaments required for printing is extremely broad. Various manufacturers offer filaments made from a wide range of plastics. These days, the range extends from conventional plastics such as PLA, ABS and ASA to PETG, nylon and high-performance plastics such as PEEK and PEKK. But as different as the filaments may be, they all have one thing in common – they must always be stored correctly in order to achieve optimum printing results. In this guide, we will show you the correct way to store filaments for 3D printing.

Photo Credits: Cults

Why Is Filament Storage Important?

First, it is important to clarify why filaments for 3D printing need to be stored correctly. Each material has different properties and characteristics, so some plastics such as nylon and PVA are more sensitive to environmental influences than others. Incorrect storage of the different materials can lead to faulty and unsightly printing results.

This can lead to extreme stringing and extremely brittle and fragile parts. Blobs on the component surface and regularly clogged print heads can also be signs of incorrectly stored filament. According to data, the strength of the material is reduced by as much as 33% if the filament has been stored in a damp environment. In order to avoid this in the future, it is important to keep some tips and measures in mind for storing your filament correctly.

As already mentioned, not every material has the same characteristics, so the “correct” storage method differs depending on the plastic. However, it is important to mention that every filament, regardless of the material, changes its printing properties under unfavorable conditions. However, there are plastics such as ABS, PLA and PETG that are more resistant and incorrect storage is therefore less noticeable than with some other sensitive materials.

Best Practices for Storing Filaments

Freshly purchased filament should be used within 12 months if possible in order to achieve an optimal printing process, otherwise care should always be taken to store it correctly in order to protect the filament. The filament should always be stored in as cool a place as possible; the optimum temperature for storage is between 15 and 24°C (59 to 75°F).

Another important aspect of storage is humidity. All plastics absorb humidity over time, but the difference lies in the amount. Plastics are divided into two categories in terms of their absorption of moisture in large quantities – hygroscopic and non-hygroscopic plastics. While less hygroscopic materials such as ABS, ASA, PETG or TPU should only be dried before use to ensure optimum printing results, certain hygroscopic plastics such as PLA, PVA and nylon absorb a particularly large amount of moisture. These do not fully regenerate after drying and are more prone to faulty and problematic printing results.

Filaments can be stored in airtight boxes (photo credits: Printdry)

Some measures can therefore be taken to protect the filaments from the effects of moisture. For example, it makes sense to store the filaments in airtight containers, ideally with desiccants. Small bags filled with sodium silicate beads are often used as desiccants. These are able to bind the resulting moisture and thus keep the filaments dry.

However, vacuum bags can also be used to store filament without any problems. There are also dedicated solutions that can be bought which are geared towards proper filament storage. If you keep these things in mind, materials that are not dry enough will no long be an issue in your 3D printing!

Have you already had experience with a brittle and fragile filament? What did you learn about filament storage? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Xometry

A very good and straightforward article. Yes I too have found PLA much more brittle compared with PETG for example. When using PLA I will always snap off the brittle section which varies in length until it starts to bend rather than snap. Very similar to preparing asparagus !!

I recently designed from scratch and have manufactured the Stylox Dry-Store Multi. A storage container which holds 4 x full reels of filament in a sealed container. The perfect size and not too large. Storing filament in unnecessarily large containers means you trap more moisture filled air than you need to and hence more moisture to contend with. The moisture is dealt with by a large vented container holding colour changing silica desiccant gel beads. This is my first product I have manufactured. I’m only selling them on Amazon UK currently as I want to test the market as well as get feedback regarding the design etc. as the intention is to roll them out into Europe and the US. I’m trying to get the price down too but anybody involved with manufacturing knows about all the hidden costs that customers just don’t see. Also releasing a single reel version very soon.