How to Dry Your 3D Printing Filament and Avoid Moisture Build-Up

Thanks to its diverse benefits, 3D printing offers many opportunities for companies to break with their usual production routines and make them more efficient. But the technology does not come without its share of challenges. Many attempts fail due to printing errors like warping or ghosting. These phenomena affect the 3D printed part quality and sometimes even its properties. One common issue? 3D printing filament not being dry.

During storage, filament may absorb moisture from the atmosphere in a very short time. If moisture remains in the material, it will cause problems. This occurs in particular with PA, TPU, PVA, PMMU or BVOH filaments, but also with PLA, PETG, nylon or ABS. Here, we will explain how to detect moisture and dry your filament to avoid these printing errors.

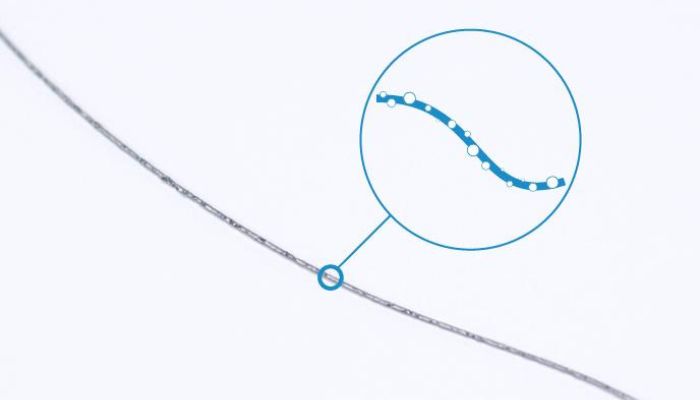

Moisture trapped in the filament (image credits: BCN3D)

Why Is It Necessary to Dry Filament?

In most cases, you can detect moisture in 3D printing filament by certain characteristics. The most obvious is the formation of water beads on the surface of your filament. But most of the time, it looks and feels just like an intact filament, and moisture can only be detected during the printing process. This can lead to under-extrusion, surface defects, filament breakage, extruder clogging, poor adhesion between layers, and, overall, brittle and fragile objects.

If the material doesn’t have a smooth surface and bubbles form under heat, you need to dry your filament. If your nozzle hisses or white smoke comes out of the machine during printing, that is also a sign that you need to dry it. Generally speaking, the biggest cues that you need to dry your filament will occur during printing.

The Measures to Take

Now that you have identified moisture trapped in the filament as the cause of printing errors, there are a few ways you can address it. One option is to place the filament in your domestic oven, preheated at a low temperature for a few hours. We recommend 40-45 degrees C for PLA and 80 degrees for ABS and nylon. However, be cautious. Using a temperature that is too high will damage your material.

Another option is to place the filament in a food dehydrator. These devices preserve food by drying it with a constant flow of air. The advantage of such a device over an oven is that you can better maintain the desired temperature. If you want to dry your filament, find out in advance what temperature the coil on which the filament is mounted can withstand.

A dedicated filament-drying machine (image credits: Fix Dry)

A more professional method is to use a filament dryer that breaks the intermolecular bonds between water and polymer at an appropriate drying temperature. The device brings the moisture outside of the filament into the ambient air, therefore drying the material. These units are equipped with a sorption unit that absorbs the filament’s moisture, which dries the filament particularly quickly and efficiently. Various models are available on the market, such as the BCN3D model. All you have to do is select the desired parameters, and the unit begins drying. This process lasts a few hours. Be aware that some filaments, like nylon, might present a problem: despite the drying process, moisture can no longer be removed due to their high absorption. As a result, the filament becomes very brittle after drying.

How to Keep Your Filament Dry

If you want to avoid ever having to dry your filament, make sure you store it correctly. In general, filament should be stored away from water and UV rays. It is advisable to place the filament in a suitable storage box with a desiccant. Some 3D printers are equipped with a filament storage unit, a handy tool because it feeds the machine directly without having to handle the spools. Whichever solution you choose, proper storage will prevent the need for filament drying, guaranteeing better results.

Have you had problems with damp filaments? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

*Cover Image Credits: BFI 3D