3D Printing on a Budget: What Do You Need to Know?

It is no secret that 3D printing is growing in popularity both at home and in industry. That is not to say that there are no obstacles that could prevent someone interested in the topic from taking it up as a hobby. The biggest one is the price. 3D printing can be expensive, between the machines, software, post-processing and of course material, the cost can creep up on users. For that reason, we decided to make a guide on 3D printing on a budget. We will take a look at everything from printer choice to filaments to software, post-processing and more to give you an accurate range for the most affordable options, including cheap 3D printers, to get into 3D printing.

For anyone who is not as well-versed on 3D printing, it is important to note that there are many technologies you can use. FDM, SLA, SLS, LPBF and more all have their benefits and their drawbacks, however for this guide we will be focusing mostly on FDM and SLA. Out of all the techniques, FDM is the most accessible to the everyday user, machines and materials often are lower cost than their counterparts. Though often not as cheap as FDM, there are also SLA printers that are more affordable, especially compared to the more industrial printers.

Budget 3D Printers

There are many different factors that affect printer price. First is, of course, the printing process used. More industrial technologies, especially those using metal, are understandably more expensive. Additionally, the size of the printer build plays a large role. However, it is entirely possible to find desktop 3D printers for under $200 using either FDM or SLA processes. Additionally, if you are willing to assemble the printer yourself, DIY kits are often more affordable than already assembled machines. Do note however, that depending on how much assembly you need to do, it could take several hours to accomplish.

In terms of printers under $200, there are a few options available. For those willing (or who prefer!) to put together their own printer with a DIY kit, Creality’s Ender 3 is one of the most popular on the market. And at a starting price of $155.00, it’s easy to see why. Creality is, in general, a popular 3D printing for its inexpensive machines, most of which can be easily found on sites such as amazon. Another Chinese manufacturer with printers under $200 is Anycubic. Out of their FDM machines, the Mega Zero 2.0 is only $189.00, though note it requires some assembly.

Anycubic’s Photon Zero (left) and the Ender 3 from Creality (right)

There are also a few SLA machines available in this price range. For example, Anycubic is also unique in that it offers one of the only SLA machines on the market that is under $200. The Photon Zero ($109.00) and Photon Mono ($199.00) are both LCD-based SLA machines, though not that compared to many of the FDM printers in the same price range, their build volume is a little smaller, which is common with SLA machines. In between the prices of Anycubic’s lowest-cost printers in the Photon series, you can find the Elegoo Mars UV Photocuring LCD MSLA 3D printer. Retailing at $149.99, it is slightly bigger than the Photon Zero though smaller than the Photon Mono. If your budget extends to $300, there is much more choice, as many of the “affordable” 3D printers are in the $200-300 range.

Budget 3D Printing Materials

Though printers are a larger investment up-front, over-time materials will likely be what drives up costs for those who want to get into 3D printing as a hobby. Additionally, with the lower cost 3D printers, you will also be limited in the materials you can use as they will only be compatible with certain filaments or resins.

Another thing to consider is that some printers will only be compatible with materials from their company. These might be more expensive than others on the market, whereas when users have the choice of material, they can choose the least expensive. Do keep in mind however that as with most things in life, often there is a direct correlation between price and properties of materials. The most affordable will certainly not be suitable for tasks beyond hobby printing.

That being said, likely if you are looking for materials, you will be buying thermoplastics, namely ABS, PETG, TPU and PLA. The four materials are some of the most commonly used in 3D printing with different properties and pros and cons. They are also the materials that are most often compatible with printers, PLA especially is widespread and able to be used with most FDM printers.

Thermoplastic filaments for use in 3D printing (photo credits: AMFG)

Even with more affordable materials, you will find a wide range for price. This is due to the properties of the material. For example, with PLA the most basic will have far worse physical properties than the high-range options. On MatterHackers, the least expensive PLA is around $18.99 ($15.59 per spool if bought in bulk) for a 1.75mm 1kg spool. However, most material manufacturers will sell PLA, PETG and TPU for somewhere in the $30-40 range.

Though resins for laser-based SLA processes can be quite expensive, the machines on our list use LCD which not only allows for more affordable machines but also resins. For example, Matterhackers’ MH Build Series Epoxy-Free 3D Printer Resin is about $27.99 for a 1kg package. Similarly, if you buy an Anycubic printer, for an extra $36, you can buy a 1kg package of resin that they have developed specifically for their machines. Though the most affordable is more expensive than the lowest cost PLA, overall resins are a similar price.

Software

One good thing about 3D printing is that many of the necessary softwares can be found online for free. For example, in order to design for 3D printing, users should have some type of modeling software, most often CAD software, and a slicer. Of course there are other softwares that can be used in 3D printing, such as optimization or workflow management softwares, but a lot can be done with just modeling and slicing. Luckily for anyone aiming to 3D print on a budget, there are many programs that are easy to use for beginners and completely free, including software programs that are open-source, meaning they are constantly updated and improved.

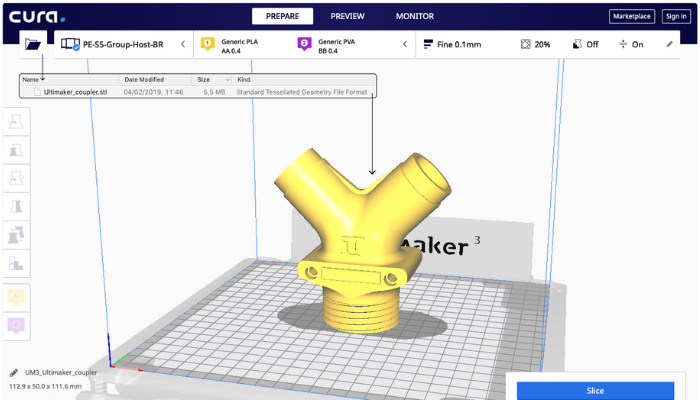

Though originally created by Ultimaker, the cura slicer is open-source and can be used with most FDM machines. Note that you will need a different slicer with an SLA printer. (Photo Credits: Ultimaker)

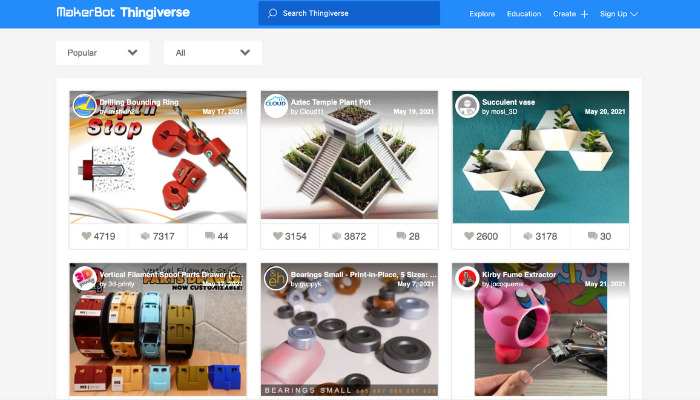

Additionally, for those who may not want to design their own part from scratch, there are many platform where already developed designs can be downloaded for free. Thingiverse for example, has millions of 3D files that have been uploaded on the site by its user community. Users will be able to download a file directly from the site and from there you just need a slicer before the file can be put into your machine. There are many other free sites where you can find these files like Cults or MyMiniFactory.

For FDM, slicers like cura are free and popular and there are many more available. Note that due to differences in the process, SLA process will need a different software or for the cura software to be heavily modified. There are still free options available however, for example, CHITUBOX basic is free and popular for SLA/DLP processes. Also make sure that whatever machine you use, you check with files it is compatible with. Most are compatible with STL files as that is the standard in the industry, but that isn’t always the case.

Thingiverse is a free platform where you can download 3D files, a good option if you don’t have much experience with 3D printing design

Though it’s not obligatory, if you are looking to get into 3D printing on a tighter budget, it would be good to consider downloading a free STL repair software online. It is entirely possible to print without this software, but considering it is available free online, it is certainly worth it. By using an STL repair software, you will be able to reduce the waste from failed prints, saving significantly on materials.

Post-Processing

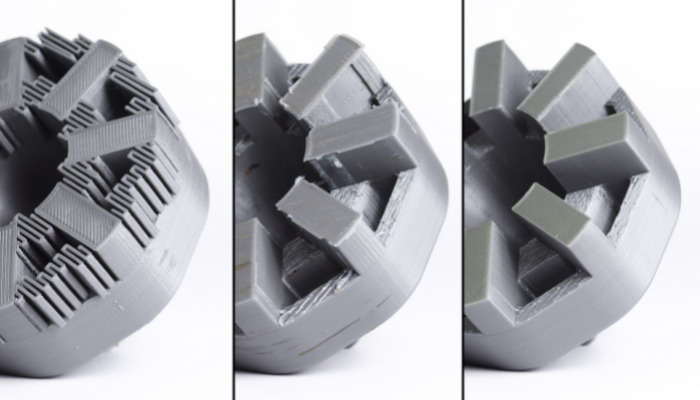

Post-processing can be a necessary step for many 3D printed parts, especially if you are using supports. With FDM printing it can be optional, though that limits the parts you can make as supports are what enable users to create parts with overhangs, or that are geometrically more complicated. Usually with FDM, unless you want a part that is more complicated, you can either buy supports that can be dissolved or use tools like needle-nose pliers to remove the extra materials, neither option thankfully is very expensive though it will add on to your budget.

Even parts made using FDM often need post-processing especially if there is support material like in the image on the left. Make sure to keep in mind the cost of tools (photo credits: MakerBot)

With all SLA/DLP processes, post-processing is obligatory. Though there are lower cost options available, Anycubic offers a wash and cure machine for only $99 which could be a good option. It is compatible with most SLA/DLP machines as well. It is also possible to buy resin cleaner to rinse the part yourself, this is usually around $10. Then like with FDM, supports can be removed with a model cutter. The final step is curing, which will always require a UV curing box. You can find these on amazon for less money, with many models on the site retailing for about $40.

So is it really possible to get into 3D printing on a budget?

All in all, even if you are buying the lowest cost for everything, 3D printing is still an expensive hobby. Beyond the initial 3D printer cost, materials will need to be continuously bought which becomes expensive over time. Depending on material, it might also be necessary to invest in adhesives to minimise warping and other issues as well. However, there are ways to reduce the costs. Generally, considering the breadth of free software available and the fact that the most affordable machine on our list is about $109 with material setting you back another $30 and a post-processing machine for an additional $40-60, it is absolutely possible to invest in 3D printing for under $200.

If you are looking into 3D printing for just a few pieces, or if you want to see whether it will be profitable for a business, instead of investing in a printer, it might be a better idea to check out some available 3D printing services. 3D printing service bureaus will quote a price and print a part on your behalf. They are a great option for when you only want an occasional 3D printed part, you want to use a specific technology that you are not trained in, or if you want to test out 3D printing for your business. Ultimately, 3D printing services are the ideal way to ensure you are 3D printing on a budget as they will enable you to get your part at less cost than investing in materials and machines.

Would you be interested in getting into 3D printing on a lower budget? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

Send me news letter

Hello! You can register for the newsletter here: https://www.3dnatives.com/en/3d-printing-newsletter/

What I am stuck on is estimating the amount of filament required for a given model. I want to print boxes for hardware storage, but I’m going to need a bunch of them. If a 1″ x 1″ x 3″ box cost $1 in filament, then that’s OK. If it’s $5 per box then it doesn’t scale. Is there any reasonable way to estimate this?

Thanks for your help!

John

Cura, for instance, will tell you what any item will ‘cost’ in terms of length of filament that will be used

As someone who works for a 3D printing company (https://hlhrapid.com/), it’s always great to see when an article highlights realistic 3D printing considerations.