How Light Reflections Could Revolutionize 3D Metal Printing

The research is intended to strengthen the manufacturing industry in the United States.

Light Reflections as a Control Mechanism for 3D Metal Printing

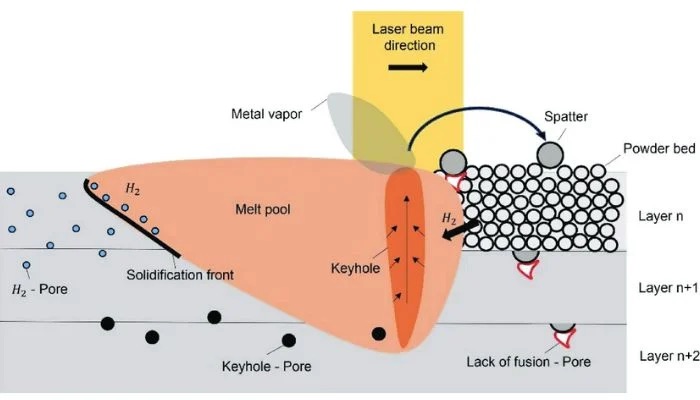

Although 3D metal printing is a highly precise technology, it is not perfect. Even the smallest variations in temperature, material properties, or printer settings can create so-called “keyholes” during the printing process. These are microscopic cavities that are nearly invisible to the naked eye but can significantly weaken the structural integrity of a part. As David Deisenroth, a mechanical engineer at NIST, explains: “It would be very helpful to monitor how the print is going in real time. Is the part getting too hot? Are there any defects? We want to be able to adjust the printer to address these problems because it will lead to stronger and more consistent parts.“

Because keyholes form within milliseconds, traditional error-detection methods are too slow. The NIST team therefore pursued an unusual approach that makes use of the light reflections described above. By observing the caustics created by the laser on the metal surface during printing, the researchers were able to detect tiny changes in the surface. This allowed them to identify when and where a keyhole was forming and even how deep it was.

The formation of a keyhole (Credit: Natan Nudelis and Peter Mayr, licensed under Creative Commons 4.0)

A Hemisphere and Laser Light Reflections

To make these light reflections visible, the team used a specially coated hemisphere that functions like a mirror. The principle is similar to a bridge reflecting the gentle waves of water on its underside. The challenge was to find a coating that reflected the laser light just once, not too much and not too little. Too many reflections would distort the image, while too few would provide no useful information. In the end, it was a simple hemisphere, originally intended as a decorative object, that provided the solution. Using it, the team was able to capture the laser’s light patterns with precision.

This technology is not yet ready for widespread industrial use. The researchers’ next goal is to integrate an extremely high-speed camera into the system, capable of capturing up to 825,000 frames per second, to analyze the laser reflections even more accurately. But even now, the research shows that caustics offer a promising approach as a control mechanism for 3D metal printing. More information can be found HERE.

What do you think about using light reflections in 3D metal printing? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Photo Credits: NIST