How Does Personalized 3D Printed Food Work?

The general consumer behavior has changed almost completely within the last decades, whether it is in the fashion, automotive, or even the food sector. Trends such as veganism or the idea of eating more sustainable and healthy food products altogether have recently become more and more prevalent. To ensure that all of the individual needs are satisfied, a variety of new possibilities in the food sector are emerging, partly also thanks to the use of additive manufacturing. In addition to that, this may also serve as a way to control global food waste and ensure safe products. For that reason, the Eindhoven University of Technology has taken an interest in 3D printed food as well.

Imagine when eating a cookie, the second bite taken from it would taste completely different than the first one did. Wondering how that might be possible? That is because, by using 3D printing, it is now possible to create completely new taste experiences. Our need for food is arguably one of the most subjective basic needs. Our personal preferences and different health aspects play a major role in what we chose to consume. As we already know from other 3D printing projects involving e of, the production, in this case, is also done by applying the edible material layer by layer. However, according to the Dutch research team from the Eindhoven University of Technology, this not only ensures the creation of unique and delicious dishes but also gives the possibility of changing the mechanical properties of our food from scratch.

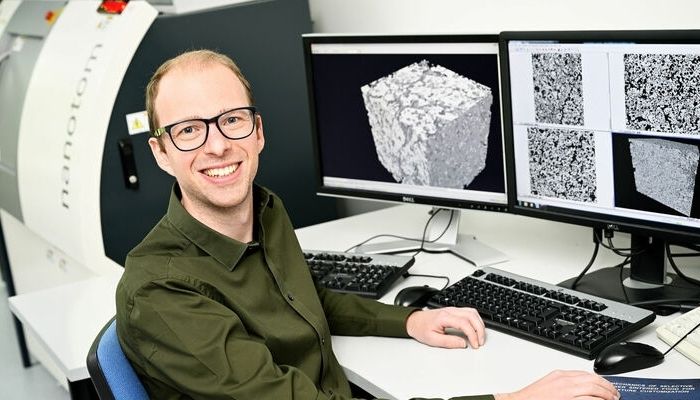

Nicky Jonkers has been working on the personalized production of food as part of his doctoral project (photo credits: Bart van Overbeeke)

How Sls Technology Is Used for the Individually 3D Printed Meal

In the Ph.D. project conducted by Nicky Jonkers, SLS technology is used to produce individual and innovative food products. The primary goal is to customize the texture property and therefore completely redefine the consumer’s taste experience. To achieve this goal and get the desired textural properties, the process conditions within the SLS process as well as the characterization of the microstructure and mechanical properties of the food are modified. Because of that, Jonkers was able to establish process-property relationships, which should subsequently contribute to the fulfillment of the target.

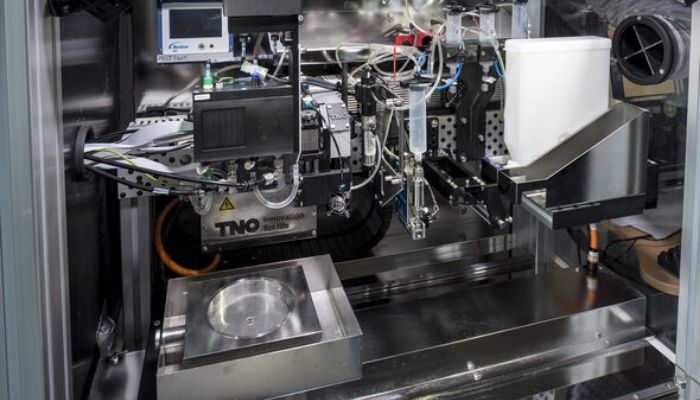

One of the SLS-based 3D printers used by Jonkers (photo credits: TNO)

Would you try the 3D-printed, customized, and probably completely new-tasting food? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.