How Ceramic 3D Printing Solves Challenges in the Semiconductor Industry

From smartphones to autonomous driving, cryptocurrencies and artificial intelligence: the demand for ever more powerful microchips is booming. At the same time, raw material shortages, trade conflicts and the tense global political situation are putting the semiconductor industry under enormous pressure. The urgent search for secure production sites is a top priority, and many manufacturers are under massive time and delivery pressure due to factory reshoring. How can all these challenges be overcome? And how can 3D printed high-performance ceramics contribute to solving the problem quickly?

In the semiconductor industry, it is important to produce quickly, precisely and cost-effectively, as the pressure to deliver and the associated costs are extremely high, especially in view of current political events, which pose additional challenges. This means that the implementation of new means must not only offer decisive added value and significantly increase production efficiency, but also address geopolitical developments. This is where 3D printing comes into play. 3D printers can be purchased quickly and moved to new locations, facilitating on-demand production and local flexibility. By using several machines together in 3D printing farms, the rapid supply of components and spare parts can be guaranteed. In addition, on-demand production means that hardly any storage space and costs are incurred. Overall, 3D printing significantly increases efficiency and stabilizes production in the face of acute challenges.

Lithoz LCM 3D print farm.

One company that has recognized the added value of additive manufacturing in the semiconductor industry is Lithoz. The Austrian company specializes in 3D printing technical ceramics and has shown in the past how its LCM technology can be used in medicine and aerospace. What’s more, the LCM process offers numerous advantages in the semiconductor industry, such as previously unattainable complex designs with smooth surfaces for critical details (for example, for high-precision channels in components for gas distribution and cooling), components with no connections and no assembly required. By integrating multiple functions into a single component and using DfAM, it is possible not only to save weight but also to increase cost-effectiveness. In addition, the LCM process enables reliable series production thanks to its stable process control.

Ceramics in the Semiconductor Industry

What are the advantages of technical ceramics in the semiconductor industry? As a rule, semiconductors are made from wafers, which in turn are made from silicon. Although silicon is available in large quantities, it has a number of weaknesses. For example, it loses its semiconductor properties at high temperatures and also has a poorer switching speed in terms of electron mobility. Silicon is therefore suboptimal for high-performance semiconductors, which are increasingly in demand. Some technical ceramics, on the other hand, meet these requirements very well.

Lithoz ultra-precision aluminum nitride heat exchanger.

These include aluminum nitride, which has high mechanical and, above all, thermal stability. It has exceptionally high thermal conductivity and thermal expansion: properties that make it particularly interesting and popular for high-performance applications. Aluminum oxide is also very popular in the semiconductor industry as it is electrically insulating and resistant to chemical corrosion. This offers significant advantages for applications in extreme or corrosive environments. Another ceramic for the semiconductor industry is silicon nitride, which is very durable and resistant to chemicals and temperatures.

Lithoz offers these ceramics for 3D printing and has already produced functional parts with representatives of the semiconductor industry using the LCM process, which combine ceramic properties and LCM ultra-precision. Examples include a gas equalizer, an ALD ring, heating and cooling plates and a gas distribution nozzle. Let’s take a closer look at one of these use cases to illustrate the potential of ceramic 3D printing in the semiconductor industry.

Lithoz gas distributors and gas flow nozzles.

3D Printed ALD Ring for Optimized Gas Flow

Alumina Systems and Plasway Technologies relied on LCM technology to design and manufacture an ALD ring. In atomic layer deposition (ALD), extremely thin layers (only one atom thick) are precisely deposited on semiconductor surfaces. To achieve this, the gas must be evenly distributed. An ALD ring ensures this by homogeneously distributing the process gases over the entire wafer surface. Integrated sensors support this, enabling real-time feedback and fine-tuned adjustments.

The companies aimed to significantly increase the efficiency of the etching and coating process for semiconductor production systems. This was achieved using LCM technology, with Alumina Systems manufacturing the ring designed by Plasway Technologies. Using a Lithoz CeraFab S320 printer, 20 ring segments of the LithaLox alumina material could be printed per platform. Six segments were then joined together to form a ring with a diameter of 380 mm. This meant that components for more than three rings could be printed per print job. The 3D printed ceramic rings not only improved the gas flow, but also enabled the companies to triple their productivity, extend the operating time from one to nine months and reduce manufacturing costs in the process.

This is just one case study of how Lithoz’ LCM technology and high-performance ceramics are helping to overcome the prevailing challenges in the semiconductor sector. Further use cases and information on Lithoz ceramics and 3D printers can be found on the website HERE.

What do you think of how Lithoz is solving the challenges of the semiconductor industry with ceramic LCM 3D printing? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

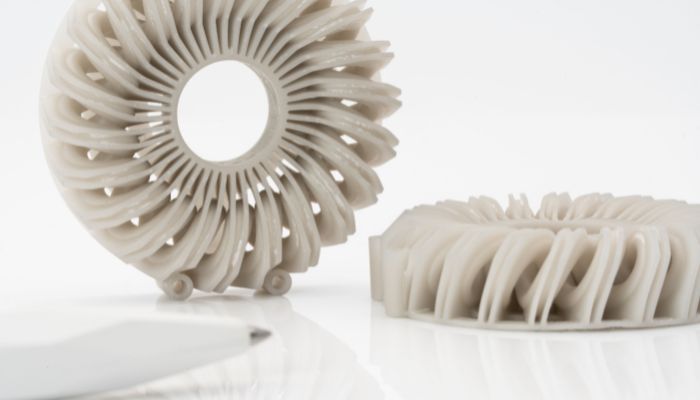

*Cover Photo: Lithoz ALD Ring, manufactured by Alumina Systems and Plasway (Photo Credits: Lithoz)