How Can We Make Metal 3D Printing More Reliable and Encourage Its Adoption?

One of the most persistent challenges in additive manufacturing is undoubtedly process reliability. How can we guarantee that 3D-printed parts will meet the desired requirements? Will they withstand the effects of time? Can we successfully reproduce the same conditions for all our parts? These issues are particularly relevant in metal 3D printing, where many professionals are still reluctant to use the technology precisely because of this lack of reliability and repeatability. What if we could develop better control over the process? Achieve more precise control and better simulation? This is the focus of research conducted at Lawrence Livermore National Laboratory (LLNL) by the Non-Destructive Evaluation (NDE) group. Their goal is to observe and analyze the evolution of materials and structures within a part during printing, and to propose techniques to ensure better quality and greater consistency of parts.

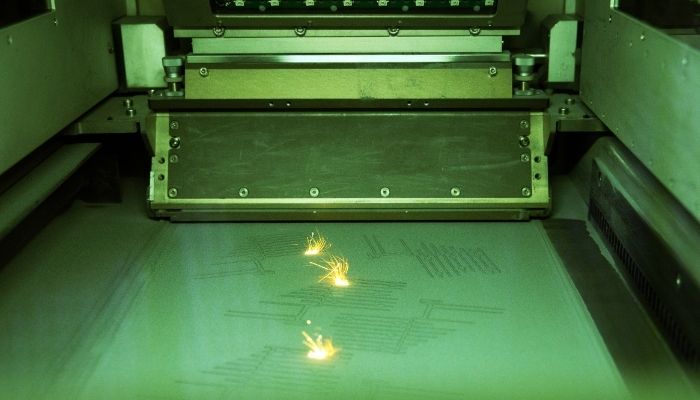

It is still very difficult to know how a 3D-printed metal part will react, as most technologies use a heat source to fuse metal particles. However, metals are particularly sensitive to heat, and these thermal changes have an impact on the structures being manufactured. The diffusion of heat in the 3D printer can affect how the particles bond together, leading to failures, defects, and therefore non-conformities.

LLNL wants to promote the adoption of metal 3D printing.

David Stobbe is the group leader for NDE ultrasonics and sensors in the Materials Engineering Division (MED). He explains: “If you want people to use metal AM components out in the world, you need NDE. If we can prove that AM-produced parts behave as designed, it will allow them to proliferate, be used in safety-critical components in aerospace, energy and other sectors and hopefully open a new paradigm in manufacturing.”

But Concretely, How Does It Work?

NDE techniques rely on a system of signals. These signals can be electrical currents, X-rays, or even ultrasound waves. They are sent through the parts being printed, and researchers then observe any changes. Take, for example, the project being worked on by Saptarshi Mukherjee, a research scientist in the laboratory’s Atmosphere, Earth, and Energy Division (AEED). He monitors the internal temperature during the powder bed laser fusion process using eddy currents, i.e., electric currents created by applying magnetic fields. These currents are sensitive to electrical conductivity. Since electrical conductivity depends on temperature, it is easy to see how these eddy currents can provide real-time information on the temperature inside 3D-printed parts.

Ethan Rosenberg, a postdoctoral researcher at MED, adds: “To our knowledge, this is the first time that eddy current sensors have been used to look at these very rapid non-equilibrium thermal processes, which are suggestive of the sort of thermal processes you would see in a metal AM process.”

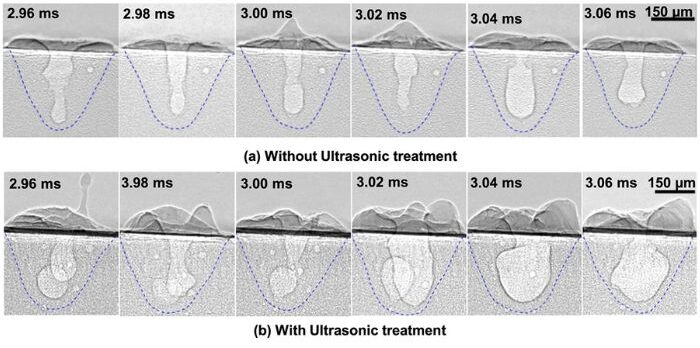

X-ray images of the dynamics of melting and solidification in a 3D-printed part, with and without ultrasonic treatment: the visible tube-shaped air holes are one of the most common defects in 3D-printed metal parts.

Today, follow-up projects have been developed based on X-ray computed tomography, electrical resistance, ultrasound, etc. Most often, these projects involve studying lattice structures or more complex geometric designs. The goal is obviously to advance this research and generalize the methods used. Ultimately, they hope to develop machine learning algorithms to monitor metal 3D printing processes in real time and correct any errors before it is too late. This could lead to much more widespread adoption of metal additive manufacturing and offer greater possibilities. In the meantime, you can find more information HERE.

What do you think of LLNL’s research into metal 3D printing? Could it help promote its adoption? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: LLNL