Hong Kong University Develops 3D Printed Airways for Burn Victims

High-degree burns often cause injuries to the respiratory tract. To treat inhalation injuries, cuts must be repaired and damaged tissue removed so that the healthy tissue can be reconnected. Researchers at the University of Hong Kong (HKU), alongside C2iTech and the Japanese conglomerate Hitachi, have developed a new approach to treat respiratory tract trauma: 3D-printed airways.

The first step for the researchers is to collect the patient’s own cells. Using a method developed at HKU, this process can be done with a single mouth swab. Using these stem cells, the scientists grow organoids, or “mini-organs,” in the laboratory that mimic the function and structure of a person’s biological organs. The researchers combine these with 3D-printed tissue to create personalized 3D-printed airways.

Fire victims often suffer injuries to the respiratory tract. (Image: Pixabay)

However, this proves to be extremely challenging, as Professor Michael Chan from the Center for Immunology and Infection points out: “Existing technologies allow the 3D printing of an airway using biomaterials. But without the cells, it cannot perform the functions of an airway.” The embedding of human cells is therefore a key element for the functioning of the airways.

It was therefore crucial for the researchers to find a way to connect the organoids to the 3D-printed tissue. “Our organoids are able to perform these functions, so we hope to put them in the 3D printed airway, [as if] we were threading fish balls onto a skewer,” explains Chan.

Another breakthrough came about through collaboration with Hitachi and HKU spin-off C2iTech, which specializes in personalized organoid cultivation. This collaboration resulted in a unique machine for producing respiratory organoids. Scientists no longer have to manually grow and care for the organoids. The labor-intensive and error-prone process is now taken over by the machine, which prints personalized organs. The machine can process 128 samples simultaneously and streamlines the manufacturing process: “The ultimate version will be creating the organoids from start to finish after the collection of stem cells,” says Chan.

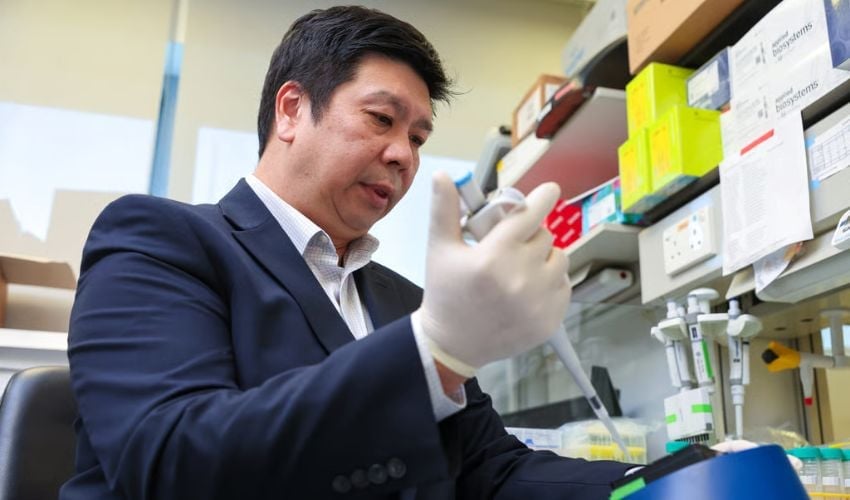

Professor Michael Chan and his team and partners are developing organoids and 3D-printed airways. (Image: Edmond So)

Organoids can be used to test how a specific person reacts to medications, diseases, and vaccinations. They represent a valuable step toward personalized medicine. “I expect organoids will become a necessity in the future. When they become widely adopted, people will no longer rely on manual work. Instead, they may hope for machines that can perform these tasks with higher efficiency,“ says Chan about the potential of organoids, adding, “Organoids can be used to see if a certain medicine is effective for you. This is what we call personalized medicine. I expect organoids will become a necessity in the future.“

The next steps are to push ahead with the automation of organoid development and improve long-term preservation. The goal is to create the organoids automatically and improve their scalability and reproducibility. These organoids could also be of interest to pharmaceutical companies for testing new drugs, as well as the commercialization of the machine itself.

What do you think of this approach to 3D-printed airways? For more information on these organoids, click HERE. Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Photo Credits: Edmond So