The High-Performance Polymer Market: An Opportunity for 3D Printing?

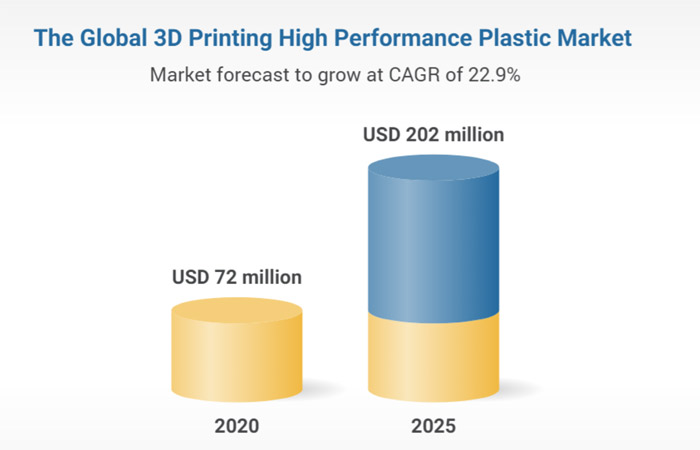

Research and Markets recently released its latest report on the Global High-Performance Materials in Additive Manufacturing Market. Entitled ‘The Global 3D Printing High-Performance Plastic Market’, it analyzes the place and evolution of high-performance polymers such as PA, PEEK, PEKK, PEI and reinforced high-performance materials. The study predicts 22.9% growth between 2020 and 2025, with an estimated market of $ 202 million in 4 years. A real opportunity for the 3D printing sector which is increasingly looking for thermoplastics with high added value, some in competition with metals due to their chemical, mechanical and thermal resistance. The report covers filaments, powders and granules as well as all the regions of the world and the different applications possible today.

High-performance polymers have been popular with the additive manufacturing market for a few years now because they offer very good properties and characteristics: high resistance to heat, chemicals and solvents, high strength, etc. Often used in sectors such as aeronautics, railways, medical or even automotive, they require demanding printing parameters, particularly in terms of extrusion temperatures and are compatible with some industrial machines.

The high-performance polymers market is expected to register an annual growth of 22.9% (Photo Credit: Research and Markets)

The most used polymers and technologies

The published report reveals that PEEK and PEKK, two materials belonging to the PAEK family, are the high-performance polymers that represent the fastest growth in both volume and value. It should also be noted that PEEK is more widely used in the medical sector. As a sterilizable material, it is particularly interesting in the production of personalized implants, especially since its properties are similar to those of human bone, accelerating osseointegration. The report also specifies that certain polymers could replace metal spinal implants and orthopedic implants.

As for the shape of the polymer as such, the filament and the granules would be the most used in this market according to the study. In 2019, the filament generated the most revenue, in particular due to the compatibility offered by FDM machines on the market. Manufacturers such as Arkema, Solvay, Evonik, or even Victrex are currently offering solutions in the form of plastic granules to meet the strong demand in the sector. However, the report specifies that the powder should experience significant growth in the coming years, an evolution which could be explained by a greater adoption of the defense and aerospace industries but also by the developments carried out on powder bed processes.

Powders could see important developments (photo credit: Evonik)

Moreover, selective laser sintering has been identified as the fastest growing technology in the high-performance additive manufacturing polymer market. The offer is currently quite limited since very few machines are compatible with this type of material, but the current developments could make it possible to broaden the applications in sectors such as consumer goods, automotive and aeronautics.

Finally, the study focuses on the most promising regions in terms of volume and value. North America and more particularly the United States would represent the main market with players such as Stratasys, Oxford Performance Materials, 3D Systems and 3DXTECH. Europe follows closely then APAC. One thing is certain, the health crisis has impacted the polymer market more generally, slowing the growth forecast a year earlier. However, additive manufacturing having made it possible to respond quickly to urgent needs in the medical sector, everything suggests that growth can quickly restart and that 3D technologies have a card to play. You can order the study HERE .

Photo credit: Solvay

Do you use high-performance polymers in additive manufacturing? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

* Cover photo credit: miniFactory