HeyGears Launches New Precise and Fast UltraCraft Reflex RS 3D Printer

When it comes to new 3D printing options on the market, it is clear that there are certain characteristics that users desire above all others. These are precision, speed and ease of use. All of which can be found in the most recent launch from HeyGears: The UltraCraft Reflex RS.

If you have not heard of HeyGears before, you probably should have. The company impressed us already earlier this year when we had the opportunity to test the UltraCraft Reflex 3D printer, HeyGears’ first foray into commercial 3D printers. There, the 10-year experience of the company was obvious, a fact that has continued with the new UltraCraft Reflex RS. Now let’s take a closer look at the most recently launched machine as well as the new resins from the manufacturer.

Two new resins from HeyGears including PAS10 modeling resin on the left and PAWW10 on the right

What Can You Expect From the UltraCraft Reflex RS?

As a brand, HeyGears is committed to “integrating future technology into life.” For this reason, it is critical for them to be able to provide solutions that address direct needs for users while being simple to use. In the case of the UltraCraft Reflex RS, this consumer-grade light-curing 3D printing is designed “for verification and rapid iteration of designs and small-batch production of consumer products, whilst aiming to reduce the technical and cost barriers to entry of light-curing 3D printing.”

The solution is posed to be a universal 3D printer that is suitable for designers, engineers and 3D printing enthusiasts with the capacity for everything from rapid prototyping to model manufacturing with a respectable print volume of 222.3 x 122.5 x 230mm. This is larger than the UltraCraft Reflex’s 192 x 121 x 220mm but the machine itself is a more compact size.

One of the major benefits of the machine is the fact that it is very accurate. Made possible by numerous features including the C5 grade z-axis module which has a precision that will meet the demands of most industrial applications. Thus, resulting in parts that are comparable to those made with injection molding thanks to stable layer thickness and clear details. Self-adapting z-axis compensation also helps to reduce stacking deformation, ultimately resulting in reduced post-processing time and cost.

Another feature increasing accuracy is the full-field precision screen. The light-curing LCD screen is divided into 60 zones, which can be calibrated through a full-screen calibration tool to ensure minimal differences in light intensity between zones. Furthermore, the Reflex RS can collect new screen data from each NFC sensor to automatically help users to complete calibration for partition deviations of around 5%, additionally the light intensity variation across all zones is around 3% This is critical for photopolymerization as it will ensure accuracy by decreasing differences throughout the screen.

Not to mention, the stability of the solution does not just contribute to the preciseness of the UltraCraft Reflex RS but also its speed along with other characteristics. Indeed, the speed of the Reflex RS has increased from the original Reflex, the average layer speed is 4.5 seconds per layer as compared to an average of 12 seconds per layer for the previous model when using the PAWW10 resin as a reference.

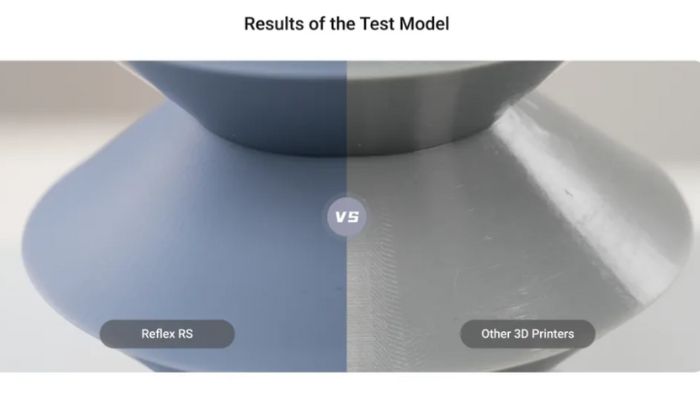

Testing from HeyGears show that with surface quality remains even during faster 3D printing

To achieve this, HeyGears has created a printer body design that is geared towards faster printing, including the C5 grade z-axis module, high rigidity printer structure and a screen cooling system. Adding to that, the printer has integrated a new Dynamic Motion Algorithm 3.0 which uses a seven-segment motion control logic for each layer with real-time data from force sensors measuring at a frequency of 80 times per second. This is critical because it allows the printer to adjust speed to the most optimal level, preventing failures such as blobs while ensuring that the part will be printed in the fastest possible time whilst maintaining precision. Other issues that will be avoided are layer misalignment and detachment issues.

Finally, one of the major benefits that HeyGears wanted to bring with this Reflex RS was ease of use. The company notes that there remain many technical barriers to entry for 3D printing and this 3D printer is their solution to this pressing issue. One of its most exciting selling points? Set-up for use is only 15 minutes according to the company.

How is this possible? Well, as we are increasingly seeing, the process for the Reflex RS is full of automated features. One-click pre-processing and slicing of 3D files with HeyGears’ Blueprint software takes just a minute and eliminates human intervention while performing automatic repairs for an improved success rate. This will eliminate holes, interference shells and other common model problems which can impede printing. There is also intelligent auto-supports for more optimized support structures.

Of course, that is only part of what makes the UltraCraft Reflex RS so easy to operate. It also has a mechanical monitoring system with force monitoring before and during printing. This enables fast detection of printing errors, with the printer even able to stop automatically as soon as they are identified. Print analysis is also done after each printing, enabling users to accurately locate any problems before the next print begins.

Last but not least, the UltraCraft Reflex RS has automated printing assistance. This includes features like automatic leveling and automatic resin refill before and during printing without supervision. An auto-heating resin tank can also be purchased separately. All of which contribute to a hassle-free process for even novice 3D printing enthusiasts.

New Resins From HeyGears

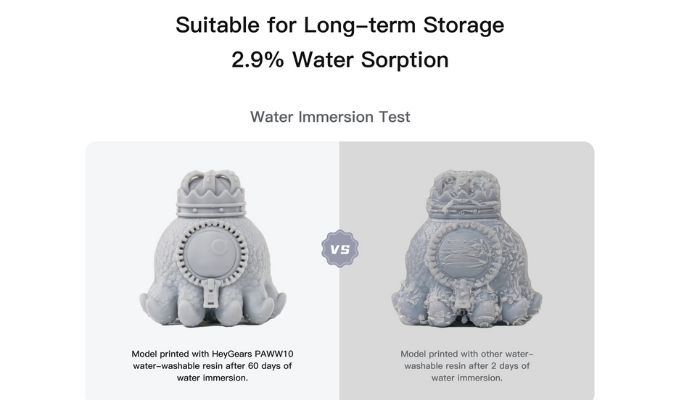

With this latest launch, HeyGears has not just released a new 3D printer, but also more resin options. For example, the PAWW10 water-washable modeling resin, which requires only a three-minute rinse with water to remove excess material and can be cured in only five minutes. This resin also has ultra-low water sorption compared to other water-washable resins. Allowing it to be stored for extended periods.

The PAWW10 is notable for its low water sorption

The UltraCraft Reflex RS will also be compatible with HeyGears’ PAS10 Standard Modeling Resin. This more affordable option is ideal for applications requiring high-quality surfaces, such as miniature models and prototype verifications, maintaining muti-batch printing consistency with a tolarance of ≤0.05 mm for users prioritizing precision and finish.

All in all, although the UltraCraft Reflex RS has just been released and only time will tell what its impact will be, it certainly shows promise. Precision, speed and ease of use are all key benefits for the average user of 3D printing technology and this printer seems to deliver.

Be sure to take advantage of the early bird offer for the UltraCraft Reflex RS, which started on September 19th, 2024, and will go through October 24th, 2024 to get the 3D printer and the combo of UltraCraft Reflex RS with RS Heated & Pulsing Release Resin Tank for a reduced price. You can find it HERE.

What do you think of the UltraCraft Reflex RS? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: HeyGears