New Heat-Resistant Alloys: In Japan, 3D Printing Pushes the Limits of Aluminum

Aluminum is considered a highly versatile material, mainly due to its characteristics of being both lightweight and strong. However, when subjected to high temperatures, its mechanical performance decreases significantly. This limitation presents disadvantages in the field of aerospace and automotive applications, where parts such as turbines and engines require thermal resistance.

To overcome this problem, researchers at Nagoya University in Japan used metal 3D printing to create a new series of aluminum alloys optimized for greater mechanical strength and heat tolerance. All of the new alloys use low-cost, readily available elements and are recyclable. Plus, one of the variants maintains both strength and flexibility at temperatures up to 300°C. The study was recently published in Nature Communications.

Going Beyond Tradition to Create the “Perfect Alloy”

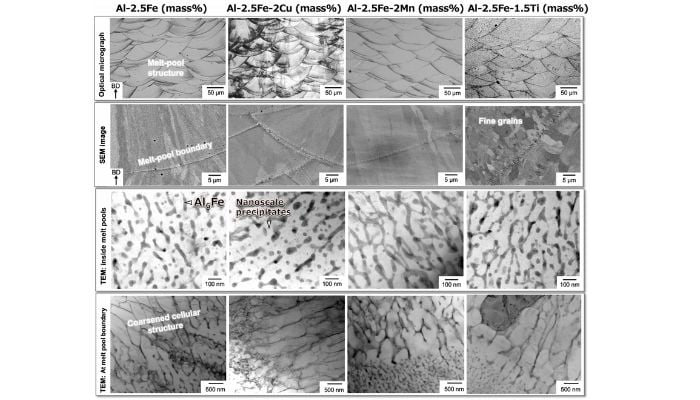

The researchers developed a systematic method to predict which elements would strengthen the aluminum matrix, and which would form protective micro- or nanostructures. They verified these predictions by creating new alloys with copper, manganese, and titanium, and then confirmed the results using electron microscopy.

The best-performing alloy contained aluminum, iron, manganese, and titanium. It outperformed all other 3D-printed aluminum materials, combining high-temperature strength and flexibility at room temperature.

Microscopic views of aluminum alloys after 3D printing. (Photo credits: Takata et al., 2025)

“The design centers on iron, which metallurgists usually don’t add to aluminum because it makes the metal brittle and vulnerable to corrosion,” explained Naoki Takata, lead author and professor at Nagoya University’s Graduate School of Engineering.

The image above shows how 3D printing changes the structure of aluminum alloys at different microscopic scales. The following processes are visible (from top to bottom): the layer-by-layer melting and solidification process, the internal grain organization that determines mechanical strength, and the distribution of microscopic particles within and at the edges of the material, key elements that influence its behavior under load and at high temperatures.

Redesigning the Internal Structure of Aluminum with 3D Printing

The breakthrough comes from the use of laser powder bed fusion. As Professor Naoki Takata explains, this technology allows iron and other elements to be “trapped” in metastable forms, results that cannot be achieved with conventional production methods. Thanks to a systematic design approach, the research team identified the elements capable of reinforcing the aluminum matrix and creating protective micro- and nanostructures, improving strength and heat tolerance without compromising printability.

Naoki Takata of Nagoya University, principal investigator of the project (left), and Masaki Kato, senior author and division manager at the Aichi Center for Industry and Science Technology (right), with the center’s laser 3D printer that creates stronger and more heat-resistant aluminum alloys.

The new alloys developed, based on aluminum and iron and enriched with copper, manganese, and titanium, combine lightness, high mechanical strength, and stability at high temperatures. The design allows the added elements to reinforce the internal structure of the metal and improve its ductility, enabling the production of higher-performance and more durable components. Furthermore, all alloys use low-cost, recyclable materials, making the solution not only technologically advanced but also environmentally sustainable.

Professor Takata also noted: “Our method relies on established scientific principles about how elements behave during rapid solidification in 3D printing and is applicable to other metals. The alloys also proved easier to 3D print than conventional high-strength aluminum, which frequently cracks or warps during fabrication.”

Lighter Vehicles, Lower Emissions

The secret to their success lies in precise control of the microstructure: certain metastable phases strengthen the metal, while titanium promotes finer grains and greater ductility. According to the researchers, this innovation promises to open up new possibilities for automotive and aerospace components, combining high performance with environmental sustainability.

The new materials could enable the manufacture of lightweight aluminum components for parts that operate at high temperatures, such as compressor rotors and turbine components.

The aerospace industry could also benefit, because aircraft engines require materials that combine lightness and heat resistance. Finally, the research provides a framework for designing new classes of metals specifically for 3D printing, with the potential to accelerate development in various industrial sectors.

Fine metal powder used to 3D print new aluminum alloys. Each particle has a diameter of less than 20 micrometers. A laser melts these particles layer by layer to build the final metal part.

What do you think of the new aluminum alloys developed by researchers at Nagoya University? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: Nagoya University