HARP 3D printer delivers record throughput in 3D printing

Researchers at Northwestern University in Illinois have developed a new 3D printer that can supposedly print at record speed, around half a yard (46 cm) per hour, a ground-breaking throughput in the world of 3D printing. The system is known as HARP (High-Area Rapid Printing) and is based on a patent-pending version of SLA technology.

Today, Carbon’s CLIP technology can be considered one of the fastest on the market. The CLIP approach shines ultraviolet light through a window into a space filled with liquid resin. The window allows oxygen to enter the liquid resin, as a result this creates a zone that resists curing, whilst above this zone the resin hardens when it comes into contact with the ultraviolet light. At the same time, a robotic attachment pulls out the solidified resin from the resin tank. The speed and strength of this technology has meant that many companies such as Adidas, Riddell or Ford have worked with Carbon to manufacture parts. However, one limitation remains: objects can be no larger than 41.4 cm by 25.9 cm at the cross section.

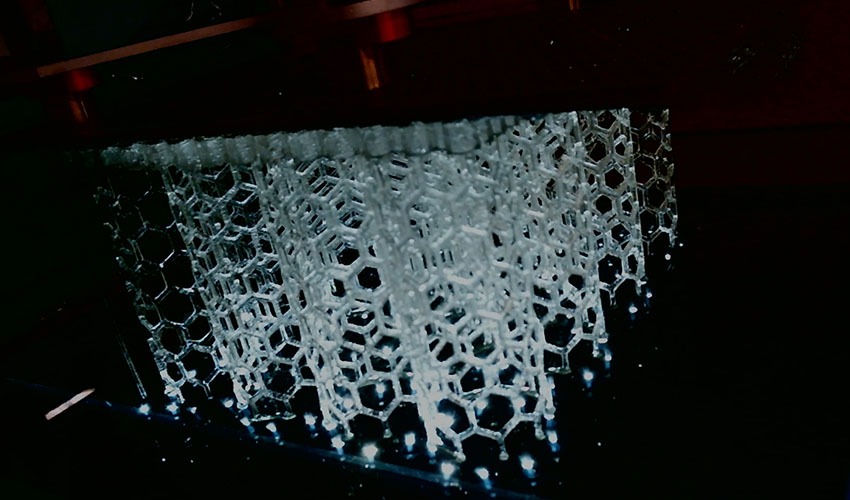

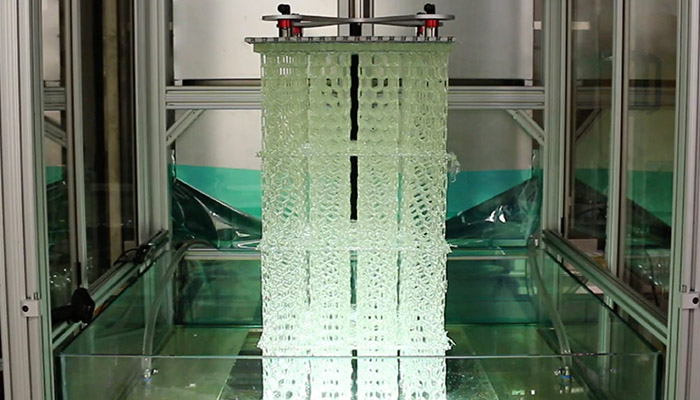

HARP 3D printing process | Credits: Northwest University

HARP’s technology can increase the throughput in 3D printing

This is what HARP’s 3D printing process could overcome. Often, the pursuit of larger parts can come at the cost of speed, throughput or resolution, but it shouldn’t be the case with this new technology. In fact, the prototype HARP technology is 13-feet tall with a 2.5 square-foot print bed and can print about half a yard (46 cm) in an hour. Chad A.Mirkin, who led the product’s development explains: “3D printing is conceptually powerful but has been limited practically. If we could print fast without limitations on materials and size, we could revolutionize manufacturing. HARP is poised to do that.”

HARP’s technology prints vertically, just like Carbon’s technology it uses ultraviolet light to cure the liquid resins into hardened plastic. It can print pieces that are hard, elastic or even ceramic. Researchers have been aware that the limiting factor is heat, which can cause printed parts to warp and crack. Therefore, to effectively dissipate this heat, parts cannot go beyond a given speed or size. When 3D printers achieve great speed, the objects need to remain small.

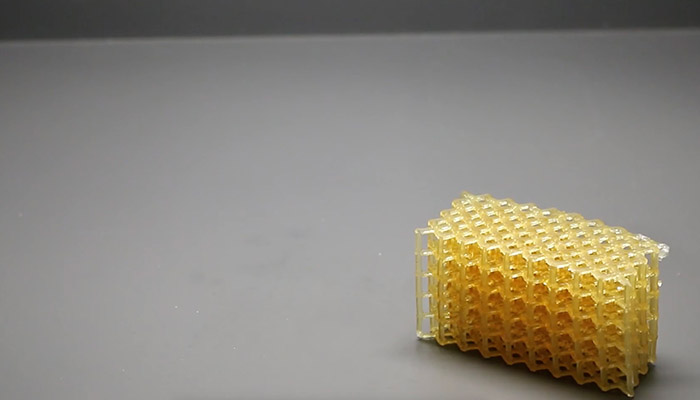

It can print pieces that are hard, elastic or even ceramic | Credits: Northwest University

To overcome this issue, researchers at Northwest University use a nonstick liquid that behaves like liquid Teflon. The liquid Teflon flows over the window to remove heat and then circulates it through a cooling unit. “Our technology generates heat just like the others. But we have an interface that removes the heat,” explained Mirkin.

Therefore, HARP is the first printer that can handle large batches and large parts in addition to small parts. Mirkin concludes, “When you can print fast and large, it can really change the way we think about manufacturing.” It’s predicted that that the novel 3D printer will be commercially available in the next 18 months.

What do you think of this new technology? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!