The Faces of Additive Manufacturing: Hanan Gothait

We continue our series on the personalities that have shaped and impacted the additive manufacturing world with our second personality, Hanan Gothait, CEO of XJet. He is behind multiple projects and the patented technology launched by the company also known as NanoParticle Jetting™. This is a groundbreaking technology as it enables production of metal and ceramic parts with the same ease and versatility as inkjet printing. We had the pleasure of discussing with him the trends in AM and his forecasts for the industry. In particular about ceramic 3D printing which is disrupting traditional manufacturing in many industries and is a segment of AM he had a lot to say about.

Hanan Gothait, Founder of Objet Geometries Ltd.

Hanan Gothait was the Co-Founder of Objet Geometries Ltd., a company that reinvented the field of 3D polymer printing with its patented PolyJet technology. The PolyJet technology was a 3D printing solution that combined inkjet technology and the use of polymers. In 2004, Hanan Gothait left Objet to pursue other projects before the company merged with Stratasys in 2012.

In 2005 Hanan became the CEO of XJet, committing to a decade of research to develop another revolutionary 3D printing technology. The company holds more than 80 patents registered and pending. Through Gothait’s guidance, XJet launched a revolutionary new additive manufacturing process, NanoParticle Jetting™, in 2016. The technology was developed for the additive manufacture of metal and ceramics and the first platforms to use it were launched a year later – the Carmel 1400 and Carmel 700 systems.

The Camel 1400 3D printing solution from XJet | Photo credits: XJet

3DN : How did the idea of bringing XJet closer to 3D ceramic printing come about?

Additive manufacturing is a well-established technology in many industries, particularly in the production of polymers and metal parts. However, the potential of 3D printing on technical ceramics is almost completely untapped. Experts predict that the global market for technical ceramic 3D printing will increase from $174 million in 2017 to $544 million by 2022, and could be worth $3.1 billion by 2027. The availability of XJet technology, the size of the potential market, the variety of potential applications and the advantages for users all point to an imminent transformation in the industry.

3DN: Can you detail how the ceramic 3D printing technology you have developed works?

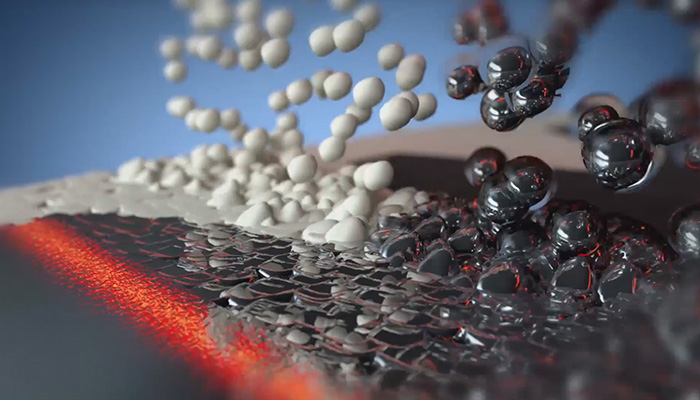

XJet’s additive manufacturing platforms are based on its patented NanoParticle Jetting technology™ (NPJ). The technology allows the production of metal or ceramic parts with the same ease and versatility of inkjet printing without compromising performance or quality. The key to NPJ begins with its unique liquid dispersion methodology. Liquid suspensions containing the solid nanoparticles of the selected compilation and support materials are injected into the compilation tray for detailed part fabrication. The nanoparticles inside the suspension are stochastic (of different shapes and sizes). Following dispersion, the smaller particles fill the spaces between the larger particles, resulting in a tight packing of the particles. This “perfect packaging” not only translates into advantages of physical properties such as high density, but also geometric advantages such as the ability to form thin walls, sharp edges, smooth surfaces and other fine details with an accuracy of 0.1mm.

The NanoParticle Jetting technology in action | Photo Credits: XJet

This is crucial for ceramic 3D printing and for achieving excellent shape and dimensional tolerance, further reducing costs and time scales. In ceramics, which is a very difficult material to machine, the ability to create complex 3D printing details and geometries is more critical than with other materials. Our technology should benefit industries such as automotive, aerospace, healthcare, dental, electronics and machinery… the list goes on and on.

Ceramic 3D printed piece | Photo Credits: XJet

3DN: How important do you think ceramic 3D printing is for different industries?

As the metal and polymer 3D printing markets have already demonstrated, the application opportunities and the time and cost savings made possible by short-term digital manufacturing are endless. Ceramic 3D printing is expected to revolutionise many industries in the same way. The health, energy and automotive industries that adopted plastic and metallic AM are already beginning exciting journeys into technical ceramics. It is expected to gain full acceptance as a valid, necessary and even preferred manufacturing method.

Ceramic 3D printing will disrupt many industries | Photo Credits: XJet

3DN: Where do you see 3D ceramic printing in 10 years?

Ceramic additive manufacturing is still in its infancy, but it is growing rapidly and we are seeing more and more applications moving from metals to ceramics. The main driving force behind this is the growing need for greater temperature resistance as well as toughness of parts and components, which pushes metals to the limit of their capabilities, where technical ceramics perform extremely well.

In the coming years we will see more and more technologies and suppliers joining this market, as well as users expanding the range of applications. It is true that today, many are waiting on the sidelines carefully reviewing market trends, but soon many of them will be launch, contributing to the exploration of this potential market. The volume of the ceramic 3D printing market is currently estimated at around $170 million and is expected to grow to $3.1 billion in 2027.

Photo Credits: XJet

However, there are some important challenges that must be met to achieve this growth, for example, education programs for ceramic engineers. As well as ceramic professionals in additive manufacturing, and much more. An essential step in this progress is the adoption of this technology by the main players in the ceramics market, including manufacturers, service providers and end users. Once this process begins, it will grow like a snowball and turn it into a legitimate and popular technology. In many ways, the growth of additive ceramic manufacturing will follow the path we saw with plastics manufacturing and, to some extent, metal fabrication.

What do you think of Hanan Gothait’s vision of the ceramics’ segment of AM? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!