Gulf Wind Technology Is Optimizing Wind Turbine Design With 3D Printing

Gulf Wind Technology (GWT) is an American company dedicated to developing wind turbine rotors. On November 20th, the company announced that it uses Stratasys additive manufacturing solutions to enhance its ability to test and improve wind turbine models. Specifically, they adopt Stratasys Neo stereolithography (SLA) technology, which dramatically reduces the design and fabrication cycle for wind tunnel models.

GWT is far from the first to leverage 3D printing for wind energy equipment production. For years, AM has been used for prototyping and creating custom parts for wind energy. Notably, General Electric began 3D printing large wind turbine components in 2019, and the startup Orbital Composites has been using on-site, large-scale additive manufacturing to build turbines, wind turbine blades, foundations and towers with funding from the US Department of Energy.

GWT can fabricate wind tunnel models dramatically faster with SLA technology

Why are these companies turning to additive manufacturing? One of the draws in this sector is the technology’s ability to create parts or prototypes faster and at a lower price-point. In the case of GWT’s wind tunnel models, additive manufacturing makes a staggering difference: a design that previously took 30 to 40 days to iterate and finalize can now be completed in just three to four days.

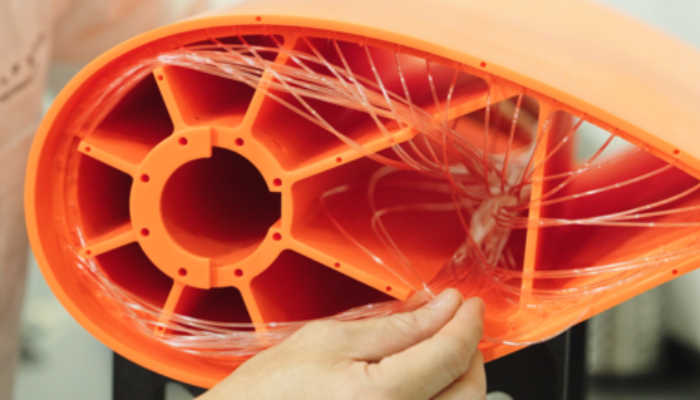

With the SLA system, efficiency isn’t the only benefit. “Additive manufacturing allows our engineers to design internal structures, and pressure taps directly into our test models, which we couldn’t achieve with traditional methods,” James Martin, CEO of Gulf Wind Technology, said. “By leveraging the Stratasys Neo® SLA system we can generate far more data in a shorter time. This has enabled us to run our design process with more rigor, become more efficient, and take on business that we previously had to turn away.”

GWT uses Stratasys’ Somos PerFORM Reflect material to print the models. The resin is favorable because it is high-strength, stiff, and temperature-resistant—all vital qualities for wind tunnel testing. Additionally, the material is easy to handle and post-processes.

An Unlikely Source of Inspiration

Using SLA technology was an innovative choice for the company. Funnily enough, the GWT engineers got their inspiration from 3D printing being used in Formula 1 racing, recognizing the technology’s potential for wind turbine design.

Rich Garrity, Chief Business Unit Officer at Stratasys, exclaimed, “Our work with Gulf Wind Technology demonstrates how manufacturers are adopting additive manufacturing where it makes the most sense for their business. By leveraging its unique advantages, Gulf Wind Technology can rapidly prototype and test complex designs, greatly improving their efficiency and ability to innovate.” To learn more about GWT’s use of SLA technology, visit the company’s website here.

What do you think of GWT’s integration of additive manufacturing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Business Wire