Graphene Improves Properties of Copper Powder used in Additive Manufacturing

In Sweden, Uppsala University and the company Graphmatech have worked together to develop a rather unusual copper powder in order to create denser 3D printed parts. Using a laser fusion process, the researchers modified the metal’s surface with graphene. Thanks to this addition of graphene, a material known for its strength, conductivity and lightness, they claim to have significantly lowered the reflectivity of copper, making it easier to use in additive manufacturing.

Recently, there have been several solutions developed based on pure copper. These have mostly relied on extrusion-based techniques where players such as Markforged or Desktop Metal have launched a pure copper filament, which vastly improves electrical and thermal conductivity. Copper, however, is one of the more difficult materials to use in additive manufacturing as it is highly reflective. As such, when a laser is used, the heat of its rays tends to be reflected rather than absorbed. The copper then retains a small part of this energy, resulting in low-density parts. Graphene could however be the miracle solution.

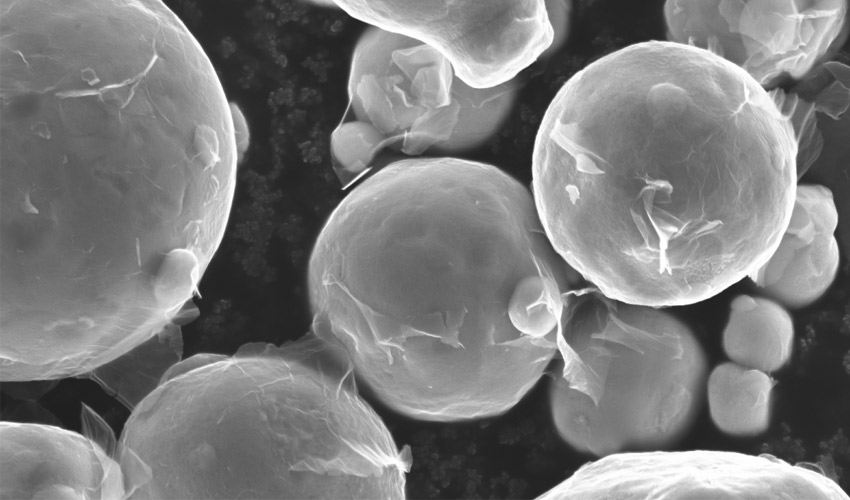

By coating copper powder with graphene, researchers have lowered its reflectivity (Photo Credit: Uppsala University).

The research was carried out by Professor Ulf Jansson at the university’s Angström laboratory. The teamed proved that by incorporating graphene on the surface of the copper powder, the reflectivity of the metal could decrease, which in turn increases the density of the 3D printed parts. Graphmatec’s CEO, Mamoum Taher, explains: “By modifying the surface of the copper powder using Graphmatech’s patented graphene technology, we successfully reduced the reflectance by up to 67%”. Researchers claim that the graphene coating on the copper powder resists well to the laser melting process, reducing the porosity of the final part.

This new hybrid material could enable the development of applications in different sectors such as defense or electronics. Professor Jansson concludes: “The new process developed to coat metal powder with graphene opens up very interesting perspectives for the design of new materials in various applications”. In any case, Graphmatec is looking to expand the use of graphene in additive manufacturing, convinced of the potential that this material could bring to the industry. In any case, we can’t wait to see future Swedish innovations! In the meantime, you can find more information HERE.

*Photo Credits : Simon Tidén / Uppsala University

What do you think about this graphene and copper hybrid material? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!