Application of the Month: GKN Aerospace Deutschland Enhances Safety and Reliability of Aerospace Components with Creaform Scanning Solutions

Aerospace is among the industries with the most stringent safety and quality standards. Aircraft and rocket components are subject to the strictest regulations and must undergo continuous inspections—both before deployment and during operation. However, precision alone is not enough in quality control; speed is just as critical. Without rapid inspections, downtime can quickly become costly. Traditional testing methods often fall short-lacking the speed, accuracy, and adaptability needed for today’s increasingly complex components.

This was precisely the challenge facing GKN Aerospace Deutschland GmbH, a global supplier of airframe structures, engine components, landing gear and other aerospace parts. With the help of Creaform’s advanced 3D scanning solutions, the company found a way to overcome these hurdles.

Creaform offers fast, precise and versatile scanning solutions

At GKN Aerospace, performance, efficiency, and aircraft safety are top priorities. Ensuring these requires rigorous and consistent part inspections. With detailed data on manufacturing equipment and components, GKN Aerospace can make informed decisions and implement corrective actions swiftly.

However, the existing touch probing systems used by the company failed to capture enough data for comprehensive analysis, offering only selective insights. Meanwhile, part geometries and customer expectations had also evolved, further complicating inspections. A new measurement solution was needed—and GKN found it in Creaform’s 3D scanning technology.

“We were looking for a metrology solution that had a high degree of accuracy and could provide a lot of data in a very short time, regardless of the part size,” explained Andreas Herkner, Site Quality Manager at GKN Aerospace. “It had to be mobile and quickly ready for use. Compatible with in-house software, we wanted the solution to offer touch-probing capabilities.”

GKN Aerospace Chooses Creaform 3D Scanning Solutions

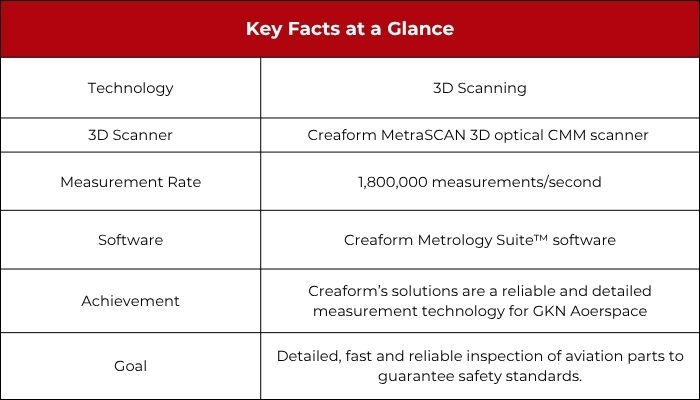

GKN found what it was looking for in Creaform’s cutting-edge scanning solutions. Headquartered in Lévis, Canada, Creaform is a pioneer in reliable, portable 3D scanners and software, notably its Scan-to-CAD solutions, which enable a seamless workflow. Ultimately, GKN selected the MetraSCAN 3D optical CMM scanner and the Creaform Metrology Suite™ software.

The MetraSCAN 3D delivers a resolution of 0.025 mm and captures data at a rate of 1.8 million points per second. This allows for rapid, high-precision scanning of even large and complex parts. Weighing only 1.49 kg, the device is extremely portable and user-friendly, making it suitable for a wide range of applications. “The implementation of the MetraSCAN 3D was seamless,” said Herkner. “The metrology team was able to integrate the system into our workflows immediately, with minimal training.”

Faster and Smarter Inspections

With Creaform’s solutions, GKN Aerospace is now able to quickly capture high-quality data, which is then compared to 3D models to enable frequent inspections of both machines and parts. This allows deviations and quality issues to be identified and resolved quickly. In turn, GKN Aerospace can respond to customer requirements faster than ever before.

The MetraSCAN 3D plays a vital role in ensuring the safety and reliability of aerospace components. It has also proven highly effective for inspecting parts subjected to extreme stress.

The MetraSCAN 3D offers outstanding accuracy and processes 1.8 million measurements per second

Herkner is fully convinced of the value of the investment: “Thanks to Creaform’s MetraSCAN 3D, we have achieved a whole new level of quality control. The accuracy, speed and user friendliness of the technology have allowed us to perform more detailed evaluations and respond swiftly to any issues,” he said. “This investment has not only improved our operational efficiency but also strengthened our commitment to delivering the highest quality aerospace components. We are extremely satisfied with the results.”

GKN Aerospace has found a strong partner in Creaform and its product offerings. Recognizing that the needs of aerospace stakeholders can vary greatly, Creaform is committed to providing a comprehensive portfolio tailored to the sector. Learn more about Creaform’s aerospace solutions HERE.

What do you think of GKN Aerospace using Creaform’s scanning solutions? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel. For more 3D printing news in the aerospace and defense sectors, check out our dedicated page HERE.

*All Photo Credits: Creaform