Why did GF Machining Solutions bet on metal additive manufacturing?

In recent years, metal additive manufacturing has taken an important place in the global 3D technology market: there has been a growth in the number of manufacturers of machines, stronger alloys and materials have emerged, software that optimizes the entire design process is available, etc. The final objective of these initiatives is to democratize its use and support companies in the implementation of reliable and sustainable technology, most often in addition to their subtractive manufacturing solutions. This is the mission of GF Machining Solutions, one of the divisions of the Swiss company Georg Fischer. It has turned to metal additive manufacturing a few years ago now and has developed an entire optimized value chain, mastering all stages of manufacturing, from design, printing to post-processing . We met Ralf Loettgen, Head of Additive Technologies at GF Machining Solutions to learn more about the group’s mission and future projects.

3DN: Can you present yourself and your connection to additive manufacturing?

Hello, Ralf Loettgen, Head of Additive Technologies, which is part of GF Machining Solutions’ Business Unit ‘Advanced Manufacturing’.

Ralf Loettgen

I have been working for GF Machining Solutions since 1993 and have been able to take advantage of its broad portfolio of machining technologies, allowing me to work in Electric Discharge Machining (EDM), before moving on to high-speed and high-performance milling and automation. I have also played an important role in managing Step-Tec’s Spindle production, and since 2015, have been responsible for additive manufacturing. Having followed the technology’s progress for quite a while, it was natural for me to accept the challenge of bringing additive manufacturing into GF Machining Solutions when the opportunity came up a few years ago.

3DN: Why did GF decide to get into additive manufacturing?

GF Machining Solutions has been following the developments in metal additive manufacturing for more than 15 years. When we renamed our company from Agie Charmilles to GF Machining Solutions in 2013, we concluded that we needed to cover this technology as well in order to provide the best end-to-end solutions to our customers. We are convinced that even though additive manufacturing will not fully substitute conventional machining technologies, more and more applications will include AM in the future. Furthermore, thanks to our extensive experience in subtractive and additive manufacturing, we are able to contribute to the development of this rather young technology. This is especially true given that additive manufacturing has now entered the serial production stage, which is always a combination of different steps. Metal additive manufacturing perfectly complements our wide technology portfolio consisting of milling and EDM machines as well as solutions for laser texturing, laser micromachining and automation solutions.

Dental bridges after the post-processing stage | Credits: GF Machining Solutions

As we did not want to reinvent the wheel in terms of developing the AM technology, we were looking for the best partner who could contribute to the core technology of metal additive manufacturing with their experience. After evaluating and testing different options, we found 3D Systems to be the right technology partner. Our capabilities and competencies complement very well and we share the same vision of preparing additive manufacturing for serial production. In the summer of 2018, we communicated our partnership, and presented the first joint solution during IMTS in Chicago in September 2018.

3DN: Manufacturing can often be complex, what help do you offer to your clients?

Complexity is the aspect where we feel that GF Machining Solutions and 3D Systems can help clients simplify their life. While additive manufacturing pioneers in the past did a great job in generating fantastic part geometries by incorporating attributes such as weight reduction, freedom of design, additional and new functionalities, the user was often left alone when it came to turning the printed part into a component that was ready for industrial use. This included the integration of the printed part into equipment like molds and engines or into the human body (implants). Only by considering the complete value chain from the very beginning to the end can the perfect solution be found. GF Machining Solutions with its unique technology portfolio and broad application experience, and 3D Systems as a leading player in the field of additive manufacturing both have the potential to deliver unique solutions to optimize the workflow across multiple process steps. This does not only take into account the physical, but also the digital dimension. This global view will influence the development of interfaces and is fueled by the exchange of knowledge among the representatives of the individual machining technologies.

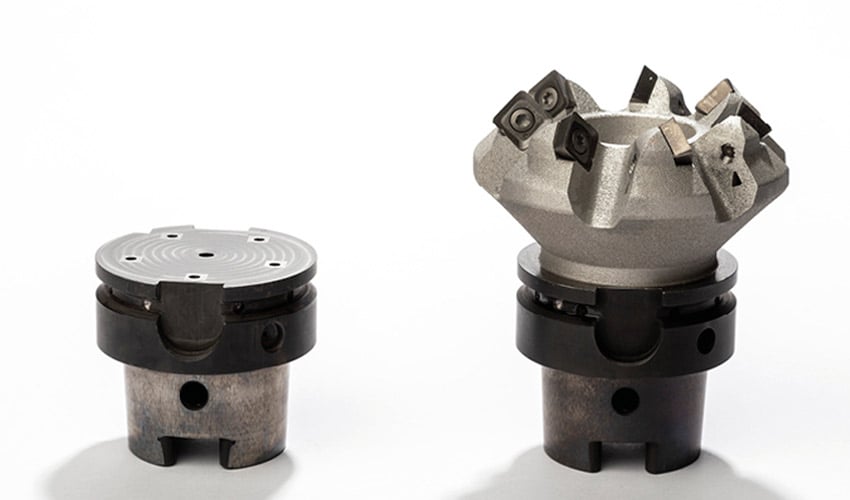

A cutting tool designed by the group | Credits: GF Machining Solutions

Additionally, 3D Systems’ Customer Innovation Centers and GF Machining Solutions’ AMotion Center are targeted at developing tailored production processes that are dedicated to specific industrial segments such as medical, aeronautic and aerospace, mold and die or general industrial parts production. The global and local organization of GF Machining Solutions offers after-sales service and application support across the globe, and is ready to support customers by keeping their equipment at productive levels and by sharing valuable application knowledge.

3DN: Why did you choose to focus on metals? What are the key applications of your machines?

If you consider the entire part production value chain, plastic and metal parts typically don’t have a lot of things in common. Since GF Machining Solutions’ product portfolio has always been focused on subtractive manufacturing technologies for metal parts, metal 3D printing was the logical addition. Here, we can add value to the entire production process and support our existing customers in their journey from design, printing and machining to the finished component.

3DN: How do you see AM co-existing with traditional manufacturing methods?

There is no real competition between additive and subtractive technologies. They are complementary technologies but they will influence each other. In order to be cost effective and deliver defined characteristics in terms of accuracy and surface finish, additive manufacturing – despite all its potential to generate additional value – will require subtractive manufacturing technologies for the preparation and the finishing of printed parts. However, a part that has been printed closely to its final shape will have different requirements in terms of subtractive manufacturing than a square block. This is not new, especially when considering that forged or cast parts represent a similar starting point for subtractive manufacturing. We are sure that additive manufacturing will change the game and will become an important tool in developing the best application in the most cost-efficient way. It is important to recognize technology synergies and develop smart physical and digital interfaces while facilitating the workflow along the manufacturing process chain by providing individual parts with references and identification.

3DN: What are your future projects?

At Formnext 2019, visitors to GF Machining Solutions’ and 3D Systems’ joint booth experienced the strategic vision of both companies, which introduces additive manufacturing into the industrial serial production process. This requires looking at the end-to-end process from design for additive to shipping of the final part. We will further focus on this end-to-end workflow and develop new approaches to significantly reduce costs by seamlessly integrating the physical and software flow and including inspection procedures.

The GF Machining Solutions and 3D Systems stand at Formnext 2019

3DN: Any last words for our readers?

Additive manufacturing is fun, but it must also generate additional value, which can only be assessed correctly when looking at a finished part that is ready to be used. This means that looking at the process from end to end is mandatory and this will determine whether the business case is feasible or not.

Visit the GF Machining Solutions website for more information.

What do you think of GF Machining Solutions arrival on the additive manufacturing market? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!