Gantri integrates its new 3D printer in its 3D printing factory

Great design ideas are more than abundant, however most of the time cost is a huge barrier to creativity and manufacturing. The company Gantri has decided to offer an alternative solution to the current industrial manufacturing model, which they argue requires too much time and money to create the first test of a design idea. In fact, they provide a digital platform where designers can develop fully-functional products wherever they are. These products are offered on their online marketplace, and once shopped they are created in real-time in their 3D printing factory in California.

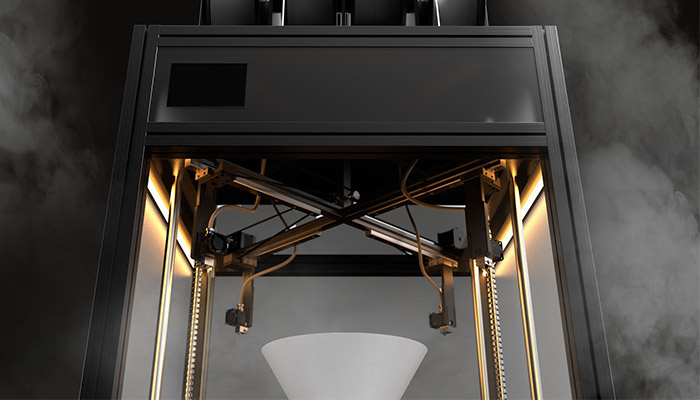

Just recently the company announced that it had developed its own 3D printer for these operations. The 3D printer is called the Dancer. On their blog, they explain the journey that lead them to the creation of this machine. They write: “We’ve quietly moved away from the idea of a printer in every home to what the technology was supposed to be all along — a revolution in manufacturing. The benefits of 3D printing are clear. Traditional manufacturing requires scale to be efficient, while 3D printing can meet or exceed quality/efficiency goals with the first unit.”

Image via Gantri

Gantri FDM 3D Printer: the Dancer

So, how does 3D printing for the home sector work out? The people behind Gantri are convinced that it’s the future of the industry. For example, the technology can adapt to the changing customer tastes and trends with no problem. However, there is still a lack of solutions for this sector. It is true that desktop 3D printers have invaded the market of 3D printers, but of course they are too low quality for these sorts of operations. When it comes to industrial 3D printers, these are too expensive and labour intensive. “As a design manufacturer, we knew that the only way for us to manufacture using 3D printing was to build our own machine — one capable of achieving industrial quality and efficiency, while retaining the flexibility of 3D printing. That’s how the Dancer Project was born.”

Some pieces from Gantri

Dancer is an FDM 3D printer – something important to the company to continue offering PLA pieces. In order to increase speed of printing, they focused on increasing the rate of flow of the material in the printer. Dancer contains 4 nozzles, working together to print each individual part. The idea is for the company to replace the 3D printers it currently owns in its factory by many Dancers. They conclude: “This move will open up new possibilities for our designers to create larger products with fewer parts, and reduce lead time for our customers.”

Image via Gantri

What do you think of creating a unique 3D printer for a company’s own 3D printing needs? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!