Frontier Bio on Overcoming the Organ Shortage With 3D-Printed Human Tissue

3D printing has profoundly transformed the medical field, bringing significant changes to the way we think about healthcare. At the heart of this transformation, Frontier Bio is exploring the opportunities offered by 3D printing and tissue engineering to grow human tissue in the laboratory. This technology opens up personalized and innovative perspectives in the field of regenerative medicine, offering customized solutions for the creation of tissues, medical devices and treatments.

At the same time, the ever-increasing number of animal experiments is becoming a cause for concern, with over 190 million animals used worldwide, and results that are not always conclusive. Frontier Bio’s main objective is therefore to design artificial tissues to replace animal experiments and contribute to the preservation of human life. The aim of these tissues? To address the growing shortage of organs for transplantation. We recently interviewed Eric Bennett, CEO of Frontier Bio, to find out more about the company’s intentions and plans.

Frontier Bio is using 3D technologies to make human tissue

3DN: Could you introduce Frontier Bio and talk about your connection with additive manufacturing?

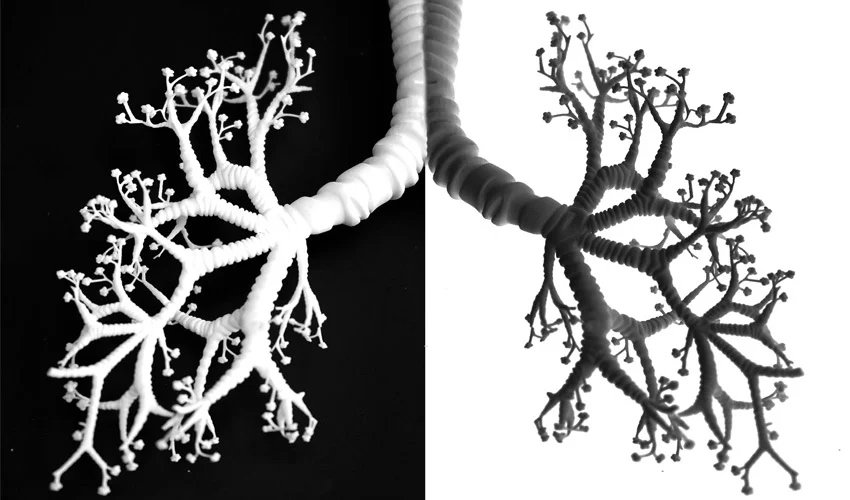

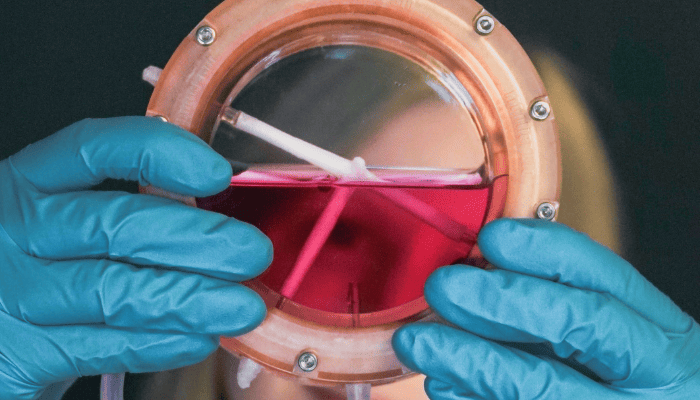

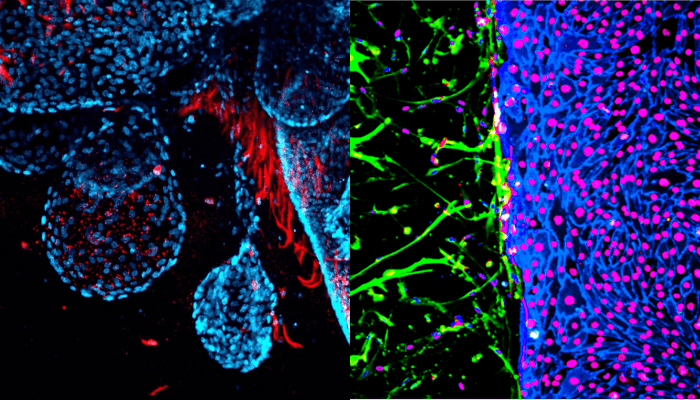

Frontier Bio is at the forefront of laboratory-grown human tissue engineering, with the ambition of revolutionizing regenerative medicine. Our mission is to develop alternative solutions for aging or failing organs and tissues, offering a sustainable answer to the shortage of organ transplants. Additive manufacturing is central to our research and product development efforts. We use advanced 3D printing technologies and self-assembly techniques to design lung microtissues, brain microtissues and blood vessels. In addition, 3D printing is used to create molds for biomaterials and for rapid prototyping of laboratory devices, illustrating our innovative approach to tissue engineering.

3DN: How did Frontier Bio come to be?

Frontier Bio traces its origins back to my tenure as CTO at Aether, where our goal was to make bioprinting technology accessible by developing affordable yet powerful 3D bioprinters. After Aether, my commitment to advancing the field of bioprinting continued, directing me towards its applications rather than focusing exclusively on hardware development. Frontier Bio was born of this vision, catalyzed by a revolutionary method I developed for manufacturing blood vessels. Our partnership with the Mayo Clinic on laboratory-grown blood vessels was a seminal project, paving the way for the innovative work we continue to pursue at Frontier Bio.

3DN: What types of 3D printing technologies are you currently using, and why did you choose them?

At Frontier Bio, we use FDM technology as well as resin 3D printing to design complex parts for equipment, molds for organs-on-a-chip, and scaffolding for tissue engineering, among other applications. In addition, our repertoire includes various 3D bioprinting techniques for tissue manufacturing. Our choice of technologies is based on their versatility and adaptability to our unique compositions of media, biomaterials and innovations, rather than on the printing methods themselves.

3DN: How is the use of 3D printing helping to replace animal studies in medical research?

At Frontier Bio, the application of additive manufacturing is fundamental to the creation of laboratory-grown human tissue that faithfully reproduces the characteristics of natural tissue. This competence is of crucial importance not only for the improvement of medical devices, but also for the accurate simulation of diseases and the search for new treatments, helping to reduce the historical dependence on animal experimentation.

Because of the differences often observed between the results of animal models and those of human clinical trials, our engineered tissues, notably lung and neural models, offer a more predictive alternative to preclinical data. In addition, our engineered blood vessels are driving a transition to human-centered trials for vascular devices, representing a significant advance in reducing the use of animals in medical device trials. This vision motivates our collaboration with the Mayo Clinic, supported by the National Science Foundation’s SBIR grant, to set new standards in medical research and testing.

The Frontier Bio research team

3DN: How do you see the future development of 3D printing in the healthcare sector?

The advancement of 3D printing in healthcare is poised to revolutionize personalized medicine, offering the possibility of tailor-made tissues for each patient on demand. This will simplify the precise evaluation of drug efficacy and facilitate the development of personalized treatments. This innovation should not only enable the introduction of revolutionary therapies for age-related conditions, but also play a role in extending human longevity and promoting a healthier lifestyle well into old age. The ability to replace organs and tissues as required heralds a new era in medical science.

3DN: Any last words for our readers?

At Frontier Bio, we are committed to advancing medical research and introducing technologies aimed at extending human lifespan. Our team is driven by the search for innovations that can redefine healthcare standards and bring about a revolution in longevity and wellness. We look forward to sharing our advances with your readers! You can find out more about us on our website HERE.

What do you think of Frontier Bio? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Eric Bennett, CEO Frontier Bio