From Waste to Wind on 3D Printing Wind Turbines Using Plastic Waste

In recent years, wind power has been developing around the world in order to provide a more sustainable alternative for electricity production. In the US for example, total annual electricity generation from wind energy increased from 6 billion kilowatthours (kWh) in 2000 to about 380 billion kWh in 2021. This accounts for approximately 9.2% of total U.S. utility-scale electricity generation according to the U.S. Energy Information Administration (EIA). And obviously, there are still many challenges to overcome, but the progress deserves to be highlighted. Among these challenges, one notable one is customers who are not always in favor of the construction of wind turbines (visuals, noise pollution, etc.), but also the recyclability of the blades produced. The Belgian association From Waste to Wind was created to address these challenges. It uses additive manufacturing, and more specifically fused deposition modeling (FDM), to design wind turbines from recycled plastic. We met its founder Bram Peirs to learn more about this ambitious project!

3DN: Could you introduce yourself and your connection to 3D printing?

Hi, my name is Bram and I am the founder of the non-profit organization From Waste to Wind. I gained valuable experience in the Flemish government, where I monitored the environmental effects of large wind turbines. Now I want to make an open-source 3D printable wind turbine available to the public with my own company. From Waste to Wind has already received an international award and additional support from the Antwerp Climate Fund in Belgium.

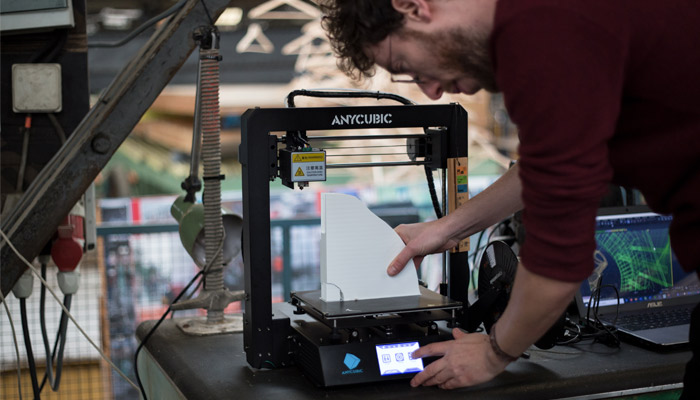

Bram Peirs holds a 3D printed wind turbine blade

3DN: How did From Waste to Wind get started? What is the idea behind it?

In the Flemish government, I have noticed that there is still a lot of resistance to wind turbines. Yet there are already quite strict rules to limit the impact of wind turbines on the environment. But people are not aware of them. They fear that wind turbines will cause noise pollution and block their view, so they don’t want them in their garden. I wanted people to look at them differently. I first made wind turbines myself out of old barrels, with magnets from old hard drives. I loved being able to make something out of nothing. I met other people on the internet who were trying to make the same thing as me and that’s how things started.

We are now working with Time Circus, an art collective that builds all kinds of things with recycled materials. They also run Loods 21 and Bar Paniek in Belgium. I learned that their homemade wind turbine had a broken blade. I restored it. The first blades were made of PVC sewer pipe, which is not very UV resistant. They also worked too well, which caused the generator to fail. I then got the idea to 3D print the blades. I bought a printer for 200 euros and was able to work with people from a Fablab in Belgium.

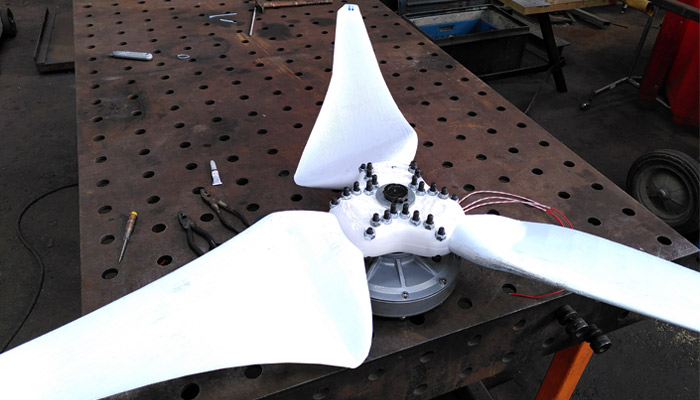

Photo Credits: From Waste to Wind

Plastic printing is not as easy as it looks sometimes, it can shrink and deform. It took us a few months to get it right. But at one point, we had printed a completely custom wind turbine, designed by ourselves, in pieces of 20x20x20 cm, the maximum volume of our printer. This wind turbine has been working well for a few months. It earned us a $10,000 prize at Hackaday, an international platform for innovative creators. That was a nice boost for us. It also confirmed that people are interested in being able to build something like this themselves.

At the same time, we also created the association From Waste to Wind. We want to break the barrier of renewable energy and small-scale wind energy in particular, and bring energy production closer to people. Our business model today is mainly to do research and raise awareness. We do this with prizes and subsidies. So far, it has worked out pretty well. We have also received a grant from the Climate Fund of the city of Antwerp. This is extremely important so that we can continue to work without depending on investors who want us to make a profit. We can set our own course and concentrate fully on our social objective.

3DN: How are you currently using 3D printing?

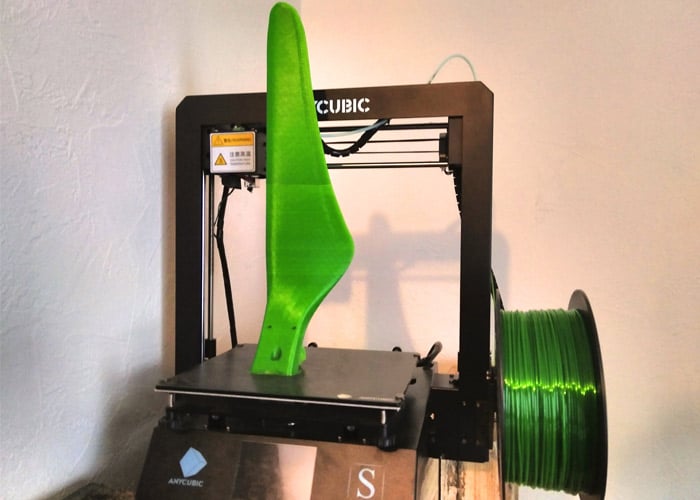

We installed a one meter long printing plate on the small Anycubic I3 Mega we started with. This was a real challenge in many ways: the plate has to be heated, which makes it shrink and expand. Also, the power cables have to travel a longer distance.

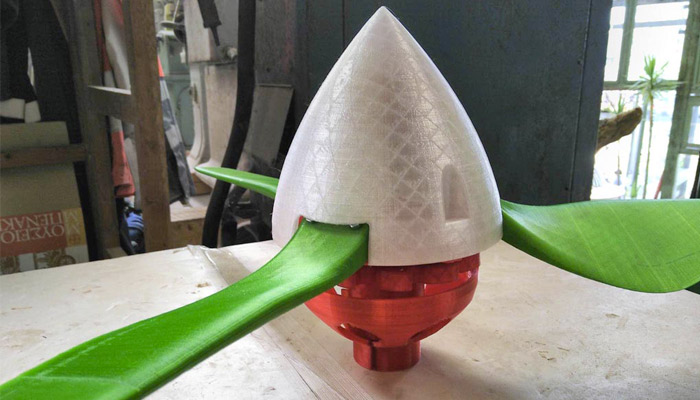

A prototype wind turbine made of rPET (photo credits: From Waste to Wind)

The big advantage of the large printing plate is that we can print blades that are one meter long in one piece. Also, printing the blade horizontally is much stronger than printing vertically, because the adhesion between the layers is not as strong. We also installed Marlin on our printer, but the more exotic features like manual leveling of the tray had many bugs. Finally, we got it to work with an older version. This allowed us to print our second prototype.

3DN: In your opinion, is 3D printing more sustainable? Can it help reduce our consumption of plastic?

Of course! First of all, there is the problem of recycling the blades. When they reach the end of their life after 20 years, the fiber and resin cannot be separated. The only thing that can be done with them is to grind them up and put them in a landfill or reuse them in asphalt. In the United States, they are buried in a landfill.

Pure plastic blades can be fully recycled, unlike the fiberglass-reinforced ones that other manufacturers use. We deliberately chose not to print with fiber-reinforced plastic, because with today’s means of recycling, the plastic remains “contaminated” and has much less potential for reuse. The only drawback is that we end up with a slightly heavier blade, but that’s not a big deal if everything is well balanced.

But we must use 3D printing wisely. Today, a lot of waste is created just for the sake of printing. Then there is the origin of the materials, which is rarely clear. For example, PLA biomaterial has to be grown somewhere in the world, then it’s transported to an industrial facility where it’s turned into filament, and I’m probably forgetting a few steps. That’s why we use rPET, which is made from recycled PET, the same plastic used for plastic bottles. It has to be recycled anyway and it’s already available locally. It also has better mechanical properties than PLA.

Photo Credits: From Waste to Wind

Finally, blades of this size are usually made with a mold and are completely solid. Printing allows us to make the blade partially hollow and save plastic.

3DN: What are the future projects of From Waste to Wind?

We could very quickly set up a production line of off-grid wind turbines (not connected to the electrical grid) with a diameter of 2 meters. But there are still so many promising new materials and techniques. We want to make larger wind turbines, 4 meters, which would produce 50% of the energy of an average family. The complementarity with photovoltaics is advantageous in Western Europe.

We want to connect all the wind turbines to the computer so that the “prosumer” can see at any time how much his wind turbine produces, but also the safety parameters, like vibrations. This is why we are making our own MPPT controllers, which will be completely open-source! In the end, our business model will probably be a bit more mixed than purely open-source. We believe that a good product will sell itself.

Photo Credits: From Waste to Wind

3DN: Any last words for our readers?

We appreciate any kind of feedback and comments about our association and the way we work and we need support. Please feel free to visit our website or write us an email at in**@*************nd.com !

What do you think of From Waste to Wind? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.