From Idea to Application: How 3devo Accelerates Material Innovation with Filament Maker TWO

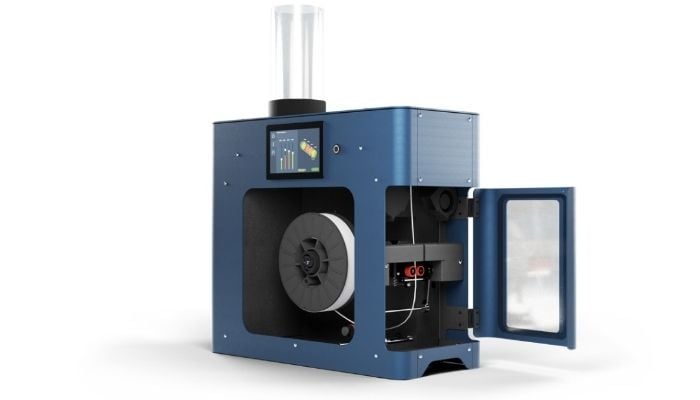

Since 2016, the Dutch company 3devo has been developing innovative solutions to accelerate the research, testing, and development of polymer materials. Known for its compact, all-in-one extrusion systems featuring a signature vertical extrusion design, the company offers machines that create filaments from a wide range of materials, including virgin polymers, advanced compounds and recycled plastics, all while offering precise control over extrusion parameters. Recently, 3devo launched the Filament Maker TWO, a lab-ready extrusion system built for engineers, scientists, and R&D teams developing high-performance filaments in-house with precision, control, and minimal waste.

The Filament Maker TWO machine is a compact, desktop-sized extrusion system designed for in-house filament development. This space-efficient footprint makes it well-suited for research labs and innovation centers where bench space is limited. Unlike traditional industrial extruders, Filament Maker TWO allows users to produce small to medium-sized batches with high precision and control. The new system has been fully redesigned with upgraded hardware to enhance thermal stability, consistency and ease of use. Key improvements include advanced sensors, a removable screw for fast purging, simplified loading and maintenance, and real-time remote monitoring of key extrusion parameters.

The Filament Maker TWO

Key Features of the Filament Maker TWO

The Filament Maker TWO combines industrial-grade features with an accessible, lab-ready design, making it ideal for R&D teams, engineers, and material developers across academic, commercial, and government sectors. Its key capabilities include:

- Compact, vertical extrusion design and all-in-one system ideal for lab-scale R&D environments;

- Advanced 3-axis filament sensor with real-time feedback and remote monitoring for consistent filament control;

- Redesigned heating & torque system for higher throughput and improved material control;

- Removable screw for minimum waste when switching materials – from standard polymers to rare or high-cost compounds.

The team adds: “Filament Maker TWO was developed in direct response to professionals seeking greater control, consistency and confidence in their extrusion process, especially when experimenting with advanced polymers or developing new applications. It’s designed to help material innovators move faster from idea to outcome with improved precision, streamlined setup and smarter feedback tools that support repeatable small-batch runs.”

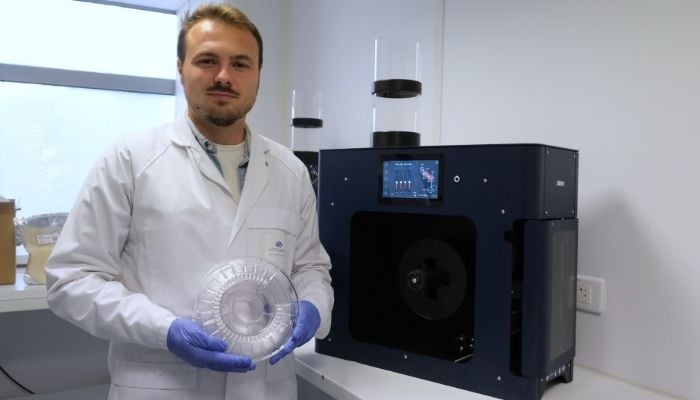

Filament Maker TWO was developed through an iterative co-creation process with active input from R&D teams and engineers. This user-driven approach allowed 3devo to refine the design based on real-world needs and performance insights. Among them is the French startup Lattice Medical, which develops bioresorbable medical implants using additive manufacturing, particularly fused deposition modeling.

Kevin Roux, Process R&D Engineer at Lattice Medical, in front of the Filament Maker TWO

Demanding Material Requirements

Lattice Medical must rely on quality materials that meet the requirements of the medical sector to print its implants. However, one of the obstacles it quickly encountered was the lack of medical-grade filaments that met biocompatibility standards. It therefore had to design its own filament, using plastic pellets that met these standards. It quickly turned to 3devo’s extrusion system, a compact, lab-ready solution that combined ease of integration with precise process control. Initially, the machine enabled the production of several implant prototypes and is now integrated into the startup’s workflow.

Lattice Medical explains: “The Filament Maker TWO is a key piece of equipment in our implant manufacturing process. It enables us to transform medical-grade pellets into a filament with controlled diameter, while preserving the material’s integrity. This filament is then used in our 3D printers. To integrate this machine into our manufacturing workflow, we had to ensure compliance with several medical device regulations. First, we carried out a full equipment qualification to demonstrate our ability to produce high-quality, reproducible filament. Additionally, biocompatibility tests were performed on the final products to confirm that no contaminants were introduced during the extrusion process.”

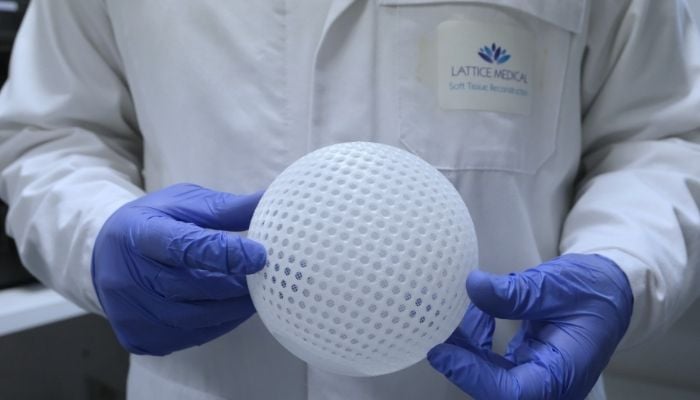

The implant produced by Lattice Medical

Why the Filament Maker TWO?

One of the strengths of 3devo’s Filament Maker TWO is its modular production volume. Unlike industrial extrusion solutions, its lab-ready design enables for smaller production runs that adapt to the user’s needs. In the case of Lattice Medical, the teams work with materials that cost several thousand euros per kilo, resulting in a production volume of less than 100 kilos per year. The Filament Maker TWO meets these specifications and even allows for individual inspection and testing of each spool produced. Furthermore, in the event of an error, only a small amount of material is lost, reducing the financial impact.

Despite its compact size, the system delivers faster extrusion speeds than most lab-scale alternatives, increasing output without compromising on precision or material integrity. Lattice Medical adds: “The FM2’s removable screw also plays an important role here, as it allows us to start extrusion directly with the material of choice without needing to purge leftover material — a valuable benefit when working with sensitive or costly biomaterials.”

Lattice Medical and 3devo teams continue their hands-on collaboration after years of working together

Lattice Medical can therefore rely on a compact and dependable system to produce a filament that meets strict medical requirements and biocompatibility standards, which is then used to manufacture a bioresorbable prosthesis. The French company also utilizes 3devo’s expertise and regularly exchanges views with the material experts on various topics: parameter optimization, clean room integration, maintenance operations, etc. The goal is to foster innovation and enable the development of impactful solutions.

With its vertical extrusion design and all-in-one architecture, the Filament Maker TWO offers a suitable solution for engineers and researchers looking to combine control, consistency and flexibility in the development of new materials. Thanks to its performance and compact size, it is positioned as an effective tool for testing, producing and ensuring the reliability of high-value filaments. Don’t hesitate to visit 3devo’s website HERE to learn more about the Filament Maker TWO and ask their experts any questions you may have!

What do you think of the Filament Maker Two? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.