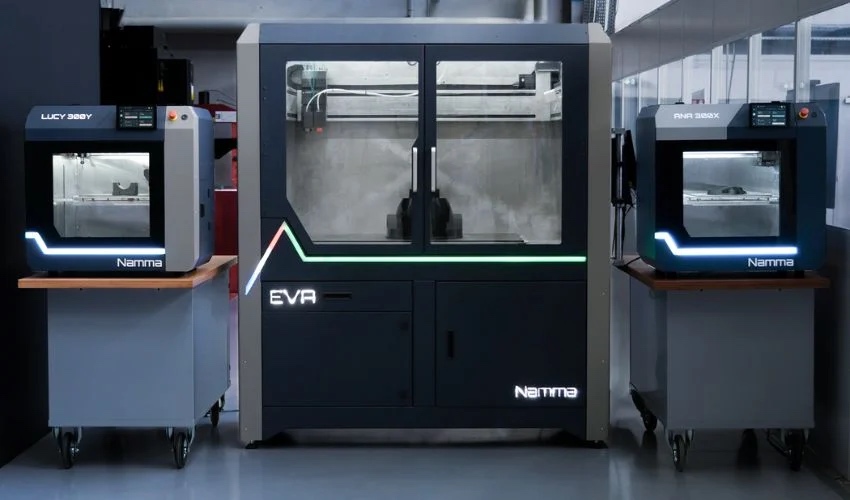

French Manufacturer Namma Expands Its Range of Hybrid Solutions to Meet Industrial Requirements

In 2021, Bordeaux-based start-up Namma presented EVA, an industrial multiprocess machine that combines three processes to produce metal, polymer and composite parts. Three years later, it has strengthened its offering with two additional models, positioning itself in both hybrid manufacturing and IDEX 3D printing. Its aim is to meet the ever more demanding needs of its users and increase their productivity. Present at Formnext 2024, the company will be unveiling its new solutions, LUCY 300Y and ANA 300X, for the first time on the international scene.

In the additive manufacturing market, more and more players are offering solutions that combine several production methods in order to shorten manufacturing times and provide a turnkey system. Combining 3D printing with CNC machining or laser engraving, for example, multiplies manufacturing possibilities and promises high-quality results, with high technical specifications. The combination of these different techniques also makes it possible to design more complex, large-format parts, while meeting the requirements of industrial sectors. This is the context in which Namma entered the market with its EVA model, a machine with interchangeable tool-heads to widen the field of possibilities.

Namma’s solutions expand manufacturing possibilities

The young French company has no intention of stopping there. It has just announced the raising of a million euros in funds to continue its R&D work, increase its production capacity and sustain its growth. It has also unveiled its new, larger premises, making it easier for its teams to work. And they haven’t been idle! Namma has expanded its range with the LUCY 300Y and ANA 300X. But what are their features?

LUCY 300Y, a Hybrid Solution for Complex, Precise Parts

Building on the strengths of the EVA model, the LUCY 300Y offers both FFF printing and CNC machining thanks to two tool heads. The special feature of the latter is that they are totally independent, and can therefore work on the same part at the same time. With a print volume of 300 x 300 x 300 mm, it is capable of designing complex parts that can be machined directly, without the need for post-processing once printing is complete. These machining steps can even be carried out in the middle of the printing process, to achieve extremely fine surface finishes (down to 0.3 microns).

Looking at the machine’s features, the LUCY 300Y is equipped with a 150°C heated build plate and a nozzle that can reach 500°C, making it compatible with a very wide choice of filaments, from carbon-fiber-filled ABS to nylon. It offers an extrusion rate of 90 mm3 per second and dimensional tolerances of ± 0.05 mm. In particular, LUCY makes it possible to manufacture precise parts with smooth surfaces, for use in demanding conditions such as plastic injection molding. Thanks to 3D printing and machining, users can quickly obtain smooth, homogeneous surfaces, ideal for guaranteeing optimal molding. What’s more, the machine is compatible with heat-resistant materials, enabling the final mold to efficiently withstand the high temperatures required for molding.

LUCY enables the manufacture of precise molds with smooth surfaces

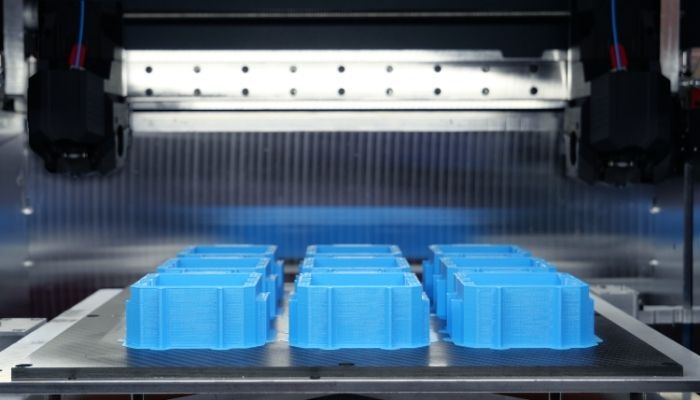

ANA 300X, the IDEX 3D Printer for Mass-Produced Parts

For its other model, Namma has opted for IDEX technology, which doubles printing speed by integrating two independent heads. These can be used to design the same part at the same time, or to print a soluble material for the supports. This makes it possible to print parts with complex geometries or pre-production runs at twice the speed.

ANA 300X has the same technical specifications as LUCY. However, it offers greater material compatibility in polymers with improved thermal, mechanical and chemical performance – and the integration of two printheads means that more substrates can be used.

One thing’s for sure: Namma’s future developments will be closely watched! If you’d like to see the machines and meet the team, we look forward to seeing you at Formnext, on stand D21 in Hall 11.1. Find out more on the manufacturer’s website HERE.

What do you think of Namma’s manufacturing solutions? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: NAMMA