Fraunhofer 3D Printed Exoskeleton Helps Patients Return to Daily Life

After accidents that damage tendons, a patient’s mobility is often severely limited. Hand injuries, in particular, can take a long time to heal and usually only recover fully through physiotherapy. For therapy, experts are increasingly using so-called exoskeletons, which are worn over the hand and specifically support hand and finger movements. Fraunhofer IWU has now developed an exoskeleton that can be tailored to each patient using 3D printing technologies.

More specifically, it uses innovative shape-memory alloys, stepper motors, and 3D printing technologies. The team emphasized that the exoskeleton must fit the patient’s hand perfectly. This is easier said than done, as every hand is different, and an exoskeleton that is not comfortable to wear can even negatively affect rehabilitation. This is where the unique properties of additive manufacturing come into play. Producing the exoskeleton with 3D printing technologies allows almost limitless customization of its structure.

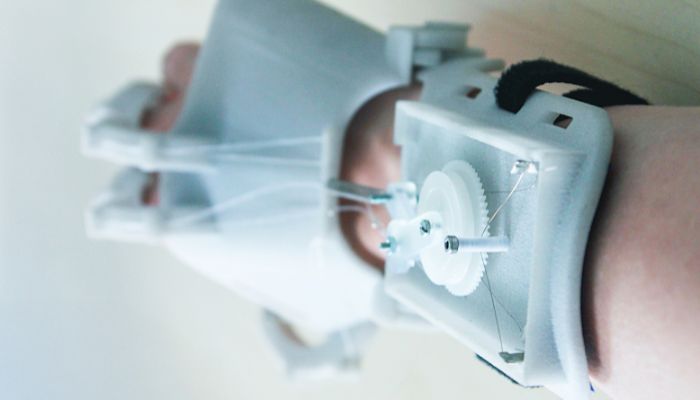

A stepper motor and wires assist the hand’s movements.

The Technology Behind the 3D-printed Exoskeleton

The team chose SLS for this purpose, a technology in which a component is built layer by layer from powder, in this case, plastic powder. For optimal customization, a digital scan of the patient’s hand is created in advance. A parametric CAD model of the exoskeleton is then overlaid on this scan so that every parameter can be precisely adapted to the individual dimensions of the 3D scan.

This allows therapists to make adjustments during the course of rehabilitation, for example, if the patient is a child who is still growing. Thanks to 3D printing, the exoskeletons are also impressively lightweight.

Artificial Tendons and More

Beyond considerations of the device’s anatomy, the hand strength of each patient must also be taken into account. Everyone has different grip strength, so the force and range of motion of the exoskeleton are individually adjustable. The researchers use a bidirectional stepper motor and wires made of shape-memory alloys. These act as artificial “tendons” that are precisely controlled by the stepper motor. If desired, these movements can also be manually fine-tuned.

In practice, the team sees the exoskeleton primarily used for accidents that result in tendon injuries. It could also support recovery after strokes or paralysis. Another notable advantage is the exoskeleton’s effectiveness in the often hectic clinical setting—therapists frequently do not have time to perform all therapy exercises with a patient. The exoskeleton can help here: exercises can be carried out with the automatic assistance of the motor, even without the constant presence of a therapist. More information can be found HERE.

What do you think of the customizable exoskeleton? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

All photo credits: Fraunhofer IWU