Flowetry Talks Providing a Customized Online Shopping Experience Using AM

Online commerce is an area that has grown very quickly in recent years, in part due to the pandemic. If you consider that, according to Statista, there are around 523 million e-commerce users in Europe alone, then it comes as little surprise that global online sales rose from $1.3 billion to $8.15 billion between 2014 and 2026. But what might the future of online commerce look like? This is a question that Flowetry has probably also grappled with, because here they have made it their mission to use additive manufacturing to create a customized online shopping experience. However, to better understand the entire background of this and to what extent additive manufacturing is now being used at Flowetry, we sat down with Sönke Hünkemeier for an interview. The founder of Flowetry gives us a better understanding of the ‘no-code’ tool for configuring 3D products for businesses.

3DN: Could You Briefly Introduce Yourself and Your Connection to Additive Manufacturing?

My name is Sönke Hünkemeier and I am the founder of Flowetry, a no-code tool for 3D product configurators. I have always been interested in additive manufacturing technologies and see them as a great opportunity for the industry to produce individual and sustainable products.

My name is Sönke Hünkemeier and I am the founder of Flowetry, a no-code tool for 3D product configurators. I have always been interested in additive manufacturing technologies and see them as a great opportunity for the industry to produce individual and sustainable products.

3DN: How Did Flowetry Come To Be Founded?

The creation of Flowetry came from the realization that many companies struggle to create and manage their 3D product configurators. Our goal is to simplify the process and make the use of 3D product configurators accessible to every company.

The future of the Internet is clearly 3D. Meta (formerly Facebook), Google and co. are all part of a giant leap away from the Internet in 2D. It makes sense: Why not experience the Internet the way you experience the rest of your life?

A similar evolution can be found in personalizable products. Everyone benefits from customized products – higher customer satisfaction and therefore fewer returns. It remains exciting to see what happens when the production of such products becomes cheaper.

3DN: What Goals Are You Pursuing Here and How Is Additive Manufacturing Being Used?

We are committed to helping companies realize their ideas and simplify the integration of modern technologies.

Although Flowetry can also be used just to visualize and experience, the focus is on personalizable products, i.e. products that can be customized to meet the customer’s wishes and preferences. This can be achieved, for example, by adding names or special designs.

Additive manufacturing enables the production of such personalized products in a particularly flexible and cost-effective way. The technology thus offers the possibility of producing personalized products in large quantities without having to manually customize each individual product. This leads to high effectiveness and enables companies to respond to the growing demand for personalized products.

Overall, it can be said that additive manufacturing plays an important role in the production of personalized products and is becoming increasingly important due to its flexibility and cost-effectiveness. We are therefore always interested in finding new ways to use this technology even more effectively.

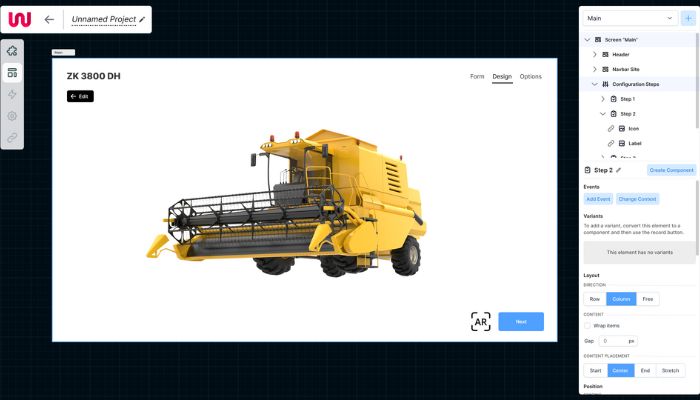

The tool interface (Photo credit: Flowetry)

3DN: You Are Dealing With the Question of How to Configure a Configurator. What Advantages Should This Offer the User in the Additive Field?

Additive manufacturing is already playing a big role for configurable products / objects. The process of playful discovery in configuring is a very powerful tool on its own. Both for the customer of an online store, as well as for prototyping.

By being able to create custom configurators for their products, companies can provide a realistic shopping experience for their customers. They can better imagine what the final result produced using additive manufacturing technologies will look like and design their desired product according to their personal preferences.

Our solution makes it possible to digitize complex products quickly, taking into account the set of rules and logic of the configurable product.

While we are still waiting for all of us to become part of the so-called metaverse, 3D digitization has many advantages even now. With our configurator, we can create arbitrary renderings of all product variants and even generate a CAD file from the configuration result.

Photo credit: Flowetry

3DN: What Can You Tell Us About Your Future Plans and Projects?

We are continuously working to improve Flowetry and add new features to provide even more capabilities to our customers. Soon, we will make Flowetry available in the form of a public beta so that interested companies have the opportunity to test our software and provide us with feedback.

In the future, we plan to further integrate Flowetry and add additional features, such as integrations with 3D printing software and hardware. This will allow our customers to make their configurators even more effective and offer their customers even more options and flexibility. We are convinced that Flowetry is an important step towards a new era of product development and configuration and look forward to offering even more possibilities in the future.

3DN: Any Final Words for Our Readers?

Finally, I would like to emphasize the importance of visualization as a tool. Humans are very visually oriented and therefore we should consider using visualization capabilities wherever possible.

We believe that additive manufacturing technologies will play an important role in shaping the future and we look forward to contributing further. If you would like to learn more, please click HERE.

What do you think of Flowetry? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credit: Flowetry