Flame Retardant Plastic Materials for Additive Manufacturing

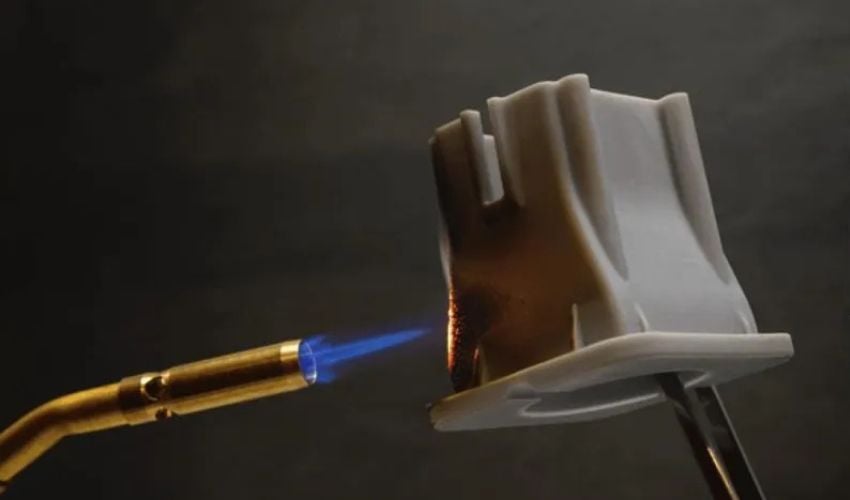

In critical applications, fire safety is non-negotiable—and 3D printing is rising to the challenge. In recent years, we’ve seen a surge in fire- and flame-retardant materials tailored for additive manufacturing, available as filaments, resins and powders. These materials are designed to resist ignition and slow the spread of flames, making them essential in high-risk or highly regulated environments. As the demand for safer, high-performance parts grows, so does the range of flame-retardant plastics adapted for 3D printing. But what exactly sets these materials apart? And where are they making the biggest impact?

Properties of Flame Retardant Materials Used in 3D Printing

First of all, it’s important to distinguish between fire-retardant and flame-retardant materials, because although the difference is subtle, it does exist. Fire-retardant materials are permanently resistant to fire, either because of their intrinsic properties or because of the way they are manufactured. Conversely, flame retardants owe their ability to slow the spread of fire to specific chemical treatments. Some are self-extinguishing, but their effectiveness depends on the coating applied. In both cases, these materials share common characteristics: they are low-flammability, emit little smoke and toxic gases, and offer controlled or reduced combustion when exposed to flames.

ULTEM 9085 is one of the high-performance, flame-retardant materials used in 3D printing.

In additive manufacturing, both types of materials are used, whether they are in the form of resins, filaments or polymer powders. These materials are categorized and certified as flame-resistant through specific tests. Specifically, plastics are tested according to UL94 regulations, an international standard developed by Underwriters Laboratories (UL) to classify the behavior of plastic materials exposed to a flame. In detail, UL94 involves testing a material according to several variables, including Horizontal Burning (HB), which is used to test whether the material burns slowly in a horizontal position, and Vertical Burning, which tests the material in a vertical position. The latter can have three grades of certification (V-0, V-1, V-2) depending on how the materials respond to the tests. The V-0 certification is the best, and it is the one that many flame-retardant or fire-retardant 3D printing materials have obtained. The main feature of UL94 V0-certified materials is that, when exposed to flames, they stop burning within 10 seconds without a fiery drip.

Also, making a brief aside for materials used specifically in the aircraft industry, there is an additional certification issued by the American Federal Aviation Administration (FAA). This is FAR Fire Test Procedure 25.853, which is used to ensure that materials used in aircraft meet specific performance criteria when exposed to heat or flame.

3Deus Dynamics has developed composite silicones via additive manufacturing for the aerospace industry. They can withstand extreme temperatures of up to 1200°C, preventing flame propagation for 15 minutes. (Credits: 3Deus Dynamics)

Flame- and fire-retardant materials can be used across a range of 3D printing technologies—from FDM and resin-based processes to polymer powder methods. When combined with additive manufacturing, these materials unlock a wide variety of applications across different industries. One key advantage of 3D printing is the precise control it offers over material behavior and processing temperatures. In some technologies, this means material properties can even be modified during printing itself. For example, composite materials can be created directly in the printing process, opening the door to advanced functionality and performance. Add to that 3D printing’s ability to produce highly complex geometries—often impossible with traditional manufacturing—and it’s clear why these materials are gaining traction in sectors where safety and innovation go hand in hand.

Applications

The applications of flame-retardant and fire-retardant materials, as mentioned above, are diverse but are mainly concentrated in industries where the risk of fire is high, such as aerospace, oil and gas, and automotive. High-performance materials, such as V-0-certified ULTEM 9085, are used, for example, for 3D printing aircraft interior components such as panels or parts of ventilation systems. These materials, which provide both high performance and a fire barrier, can also be used in the automotive and transportation sectors to additively fabricate interior parts of train cars or elements of automobile bodies, but not only that.

Parts for the electronics industry 3D printed with Cubicure Evolution FR resin (Credit: Cubicure).

Other types of materials, such as resins, an example being Cubicure Evolution FR (UL94 V0), are also used in the electronics industry for additive manufacturing of small, detailed parts that serve to prevent the spread of flames in the event of a short circuit or fire. In addition, these materials also have applications in sectors where high safety standards and compliance with fire regulations are required. Think, for example, of the construction sector, where it is possible to 3D print fireproof ceilings, doors or siding, or even the medical sector, where some medical equipment and devices are made from fireproof materials to meet high safety standards.

What do you think of 3D printing with flame-retardant materials? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Formlabs