Firehawk Scores $60M Investment Led by 1789 Capital, Firm Tied to Trump Jr.

Firehawk Aerospace, a Dallas-based defense company specializing in 3D printed solid rocket fuel, has just received a $60 million Series C investment led by 1789 Capital. The company’s mission is to enable the next generation of defense systems with solid rocket motors powered by additively manufactured propellant. Firehawk claims that this propellant is cheaper and faster to produce than traditional propellant, all while being safer, more reliable and higher performing.

According to Forbes, 1789’s investment in Firehawk is the firm’s first defense tech venture. They offered $15 million for the deal, which should close this month, along with checks from other firms like Draper Associates and Boka Capital. 1789 Capital, named for the year the Bill of Rights was written, was founded in 2023 by Omeed Malik to invest in non-“woke” companies to form a “parallel economy,” i.e., an alternative to the one participating in the “woke” agenda. The firm’s website promises to invest in “Entrepreneurship, Innovation and Growth” and is notably “Anti-ESG,” ESG referring to Environmental, Social and Governance, shorthand for an investment principle that prioritizes environmental, social and corporate governance issues. Donald Trump Junior, son of President-elect Donald Trump, recently joined the firm as a partner.

The Firehawk CEO Will Edwards

An Inherent Link Between Aerospace and Defense?

While rocket fuel, as used for aerospace, is not inherently political, its counter-use, in defense, certainly is. After all, rocket propellant is used for space rockets, as well as missiles. Is it possible to distinguish between the two sectors? To garner enough funding for research, Firehawk’s CEO and founder Will Edwards explained that it was necessary to blur the lines. In a 2023 interview with Space Insider, he exclaimed: “Every space company is a defense company.” For Edwards, it was especially necessary to highlight the overlap for investors, because futuristic space endeavors could lack the near-term revenue opportunities they seek.

Ultimately, the company is positioned to service the United States. Edwards told Forbes, “My big investors in later stage happen to be politically outspoken, [but] we do have investors on the cap table who are pretty far left…there’s no motive beyond doing what’s best for our country, and our company.” In Forbes, Malik shared 1789’s motive for its investment in Firehawk. “There’s a missile shortage in the United States,” Malik said. “This is part of a defense tech investment that enhances the security and competitiveness of the United States.”

Why 3D Print Rocket Fuel?

Rocket fuel provides a solution for storable “delta V,” which means changing relative velocity, the result of a rocket firing. There are liquid propellants, which boil off, and solid propellants that are single-use. So, the Firehawk team developed a hybrid, thermoplastic-based system, apparently capable of increasing efficiency and reducing supply chain constraints. Dr. Justin Karl, the Chief Engineer of Firehawk Aerospace, explained why and how his company additively manufactures rocket fuel in the same interview for Space Insider: “Our 3D printing is really just fancy plastics that have roughly the same chemical makeup as the fuels that have been used for decades and decades, but they perform better because you can tailor those surfaces perfectly. …[Using] layer by layer deposition, there’s no chance of getting gaps or bubbles or any deficiencies.”

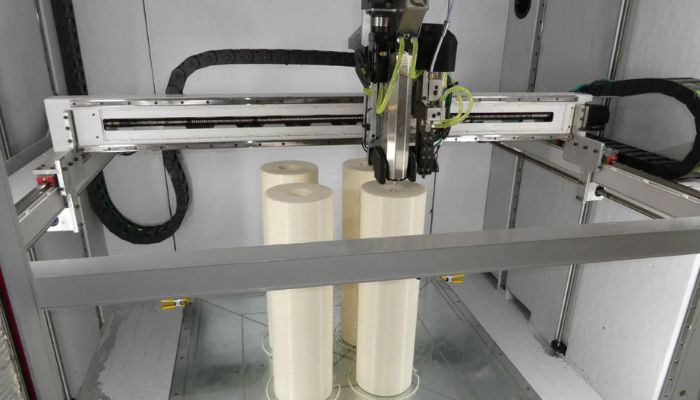

Firehawk’s 3D printer

Today, rocket engine propellant is made using a casting and curing process, which can take as long as two months to produce. By contrast, Forbes reported that Firehawk claims its propellant can be made within hours using an off-the-shelf 3D printer. What’s more, the fuel can be made almost anywhere that can accommodate a 20 by 40-foot shipping container—even on the battlefield.

Government and Commercial Partners for Testing

Edwards contributes a large part of his company’s success to their partnerships. “We have some of the biggest companies in the world coming into our facilities, that we’re [then] working with and securing large contracts through our partnership approach,” Edwards told Space Insider in 2023. To date, those partnerships have continued to grow, including a trial contract with Army Applications Laboratory, work with Raytheon and trials with the Air Force Research Laboratory and NASA. To Forbes, Edwards expressed his determination to change the rocket propellant landscape. “Either Firehawk is going to be the company that makes 3D printing solid propellant the industry standard,” Edwards said, “or we’re going to shut our doors.”

What do you think of Firehawk’s 3D printed rocket propellant? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! For more on aerospace and defense, check out our dedicated landing page. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Firehawk