A filament based on boron carbide, one of the hardest materials on the market

Additive Composite and Add North are two Swedish companies that have worked together to develop a composite filament based on boron carbide, one of the hardest materials on the market after diamond and cubic boron nitride. Marketed under the name Addbor N25, it is made of nylon to which boron carbide has been added: the aim of the two companies is to offer a filament capable of resisting radiation.

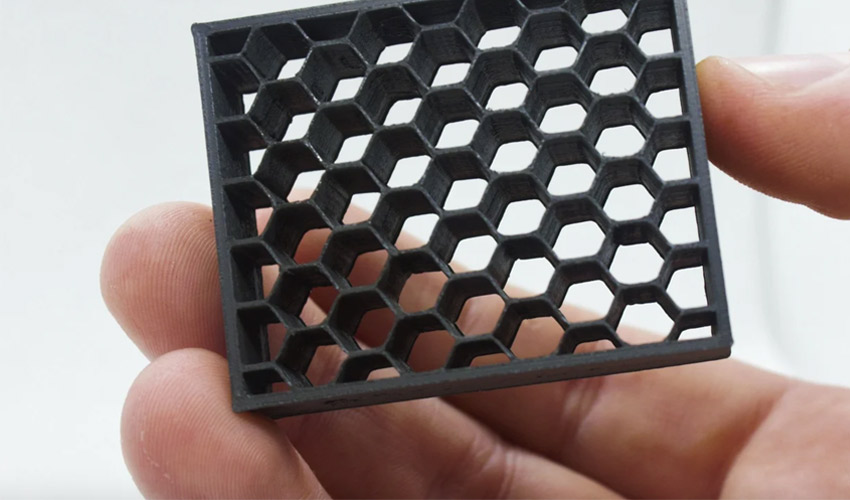

Last week, we spoke to you about composite 3D printing, its advantages and the technologies available on the market. It was explained that most composite materials are made of carbon fibre, but also glass or aramid. It therefore appears that boron carbide is quite innovative in the additive manufacturing market. It is a mineral material with very high hardness, low density and extremely high temperature resistance, ideal for shielding and nuclear applications for example. Due to its properties, Additive Composite and Add North have chosen it as a component of their new 3D printing filament.

Boron Carbide is one of the hardest materials on the market.

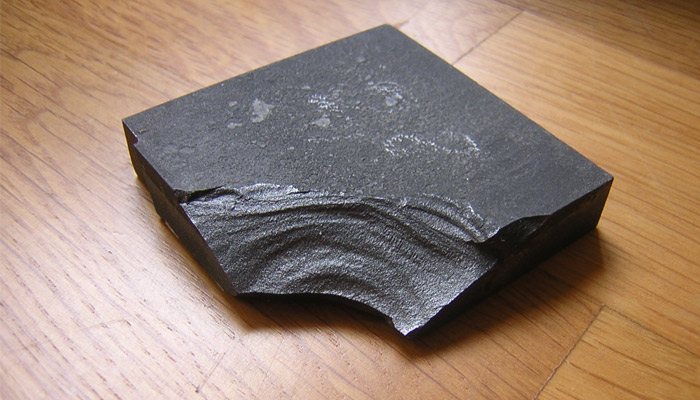

Addbor N25 would be made of 25% boron carbide, the rest being nylon: Add North points out that this technical polyamide already has interesting characteristics for the industry such as its strength and low shrinkage. It is therefore reinforced by boron carbide which ensures effective absorption against neutrons and therefore shielding capabilities against radiation. Adam Engberg, CEO of Additive Composite, adds: “Additive manufacturing changes the number of products designed and manufactured. We believe that Addbor N25 contributes to this development and helps both industry and large research facilities to replace toxic materials that could eventually contaminate the environment. Our new product is the first in a range of radiation shielding materials that we are currently developing.” Indeed, the composite replaces certain metals such as cadmium, a material banned from the market because of its high toxicity.

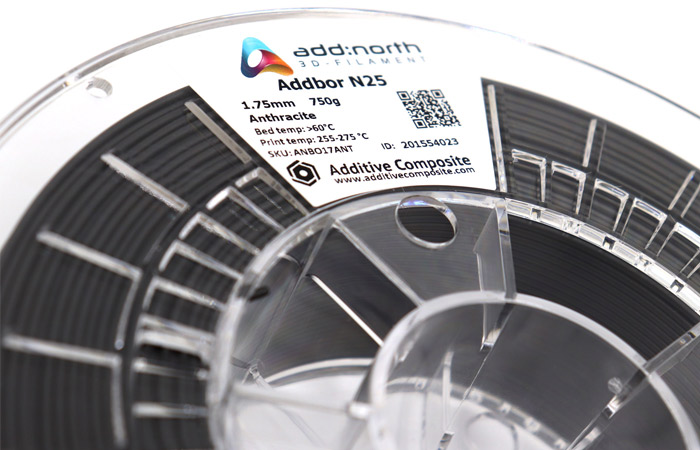

The composite filament is available in the form of a 750-gram spool.

As far as printing characteristics are concerned, Add North advises to use hard nozzles with a diameter of 0.4 mm because boron carbide is abrasive, with an extrusion temperature between 255 and 275°C and a temperature of 60-75°C for the tray. Finally, it is necessary to count 11,875 Swedish crowns for a 750-gram spool, i.e. approximately $1,220! For this price, you better not mess up any print… You can directly buy the material on the Add North website. What do you think of this new composite material? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox.