FDM vs SLA: Which 3D Printer Should You Buy?

Despite a host of different 3D printing technologies arising since its inception, the purpose has remained the same: convert a digital model into a physical one. However, each technology has different techniques, developments, and results. We have compared two of the best-known technologies in the industry today: FDM & SLA. There are several types of FDM 3D printers, which we will compare with their resin 3D printer counterparts.

First Developments

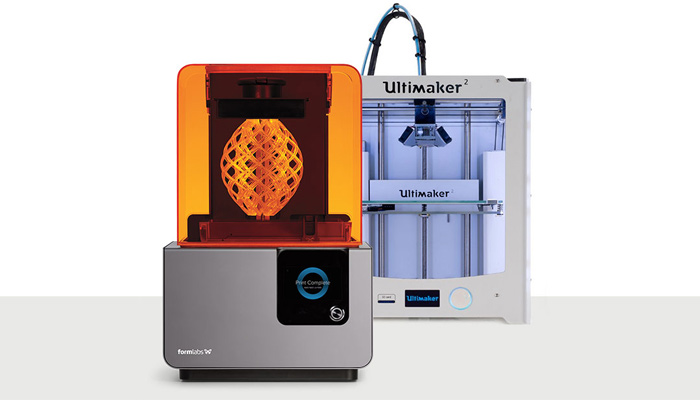

Stereolithography (SLA) was the first 3D printing technique. Its first developments began in 1986 when Chuck Hull, 3D Systems’ founder, registered the first commercial patent for the photopolymerization of a resin through laser. Years later came DLP technology, based on the same technique but using light generated by a projector. In the development of SLA/DLP printers, companies like Formlabs, B9Creations and Carbon 3D grew large.

A few years later in 1988 Scott Crump, founder of Stratasys, unveiled the first FDM (Fused Deposition Modeling) or FFF (Fused Filament Fabrication) printer. This technology became popular because of its easy handling and low price compared to other technologies. The development in FDM allowed companies like Ultimaker, Makerbot and Zortrax, to become big brands.

Materials

FDM technology is the most popular and also the most accessible; so many materials have been developed. These include basic PLA and ABS plastics, but also multiple materials that have adapted such as wood, cork or coffee. This has also led to the development of an immense amount of colors, as well as flexible materials. The filament diameters of this technology are 1.75 or 2.85mm, and some brands have developed their own filaments adapted to their machines such as Zortrax.

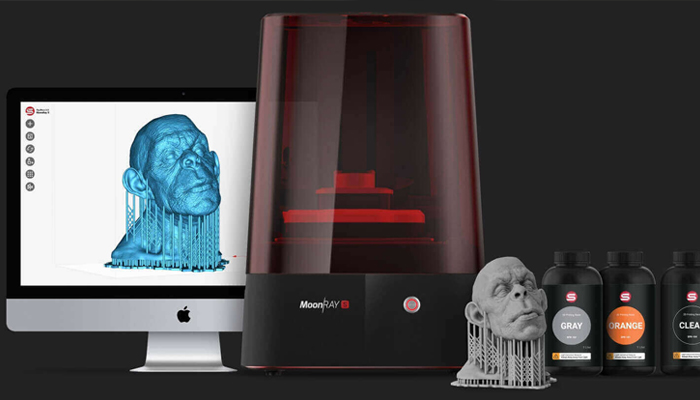

In SLA technology, resins are used. This means more limited colors, at a slightly higher price. The difference here is that the resins are difficult to interchange, and depends on each manufacturers’ specifications: machines like the Form 2 have only black, white, gray and transparent resins.

Print Quality

One of the key differences between the technologies is print quality. SLA is known to be of a significantly higher quality print than FDM.

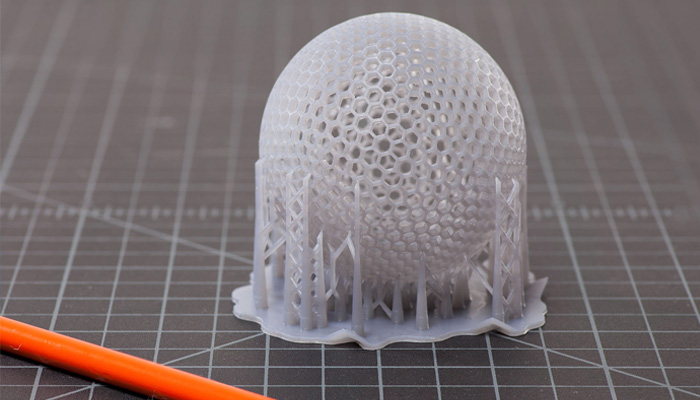

In SLA the optical point of the laser, or projector determines the resolution of the model. In addition, the printing does not physically print since it uses light for its polymerization. This results in much smoother surfaces, reaching layer sizes of 0.05 to 0.01 mm.

With FDM technology, the resolution is directly related to the size of the extrusion die and the precision of the extruder movements (X / Y axis). This means it is of utmost importance to properly calibrate the machine. Often the quality varies according to the machine, its precision and softness of impression, since the weight of the layers can displace the bottom layers, reducing quality. Layer thickness of an FDM printer ranges from 0.5 to 0.127 mm.

A model created through stereolithography

Post-processing

When our 3D printer finishes its work, it does not mean that ours has. All 3D printing technologies needs a post-process, which can range from the detachment of the piece and a small amount cleaning, to hours of work.

In the case of FDM technology the post processing is relatively simple: remove the supports and remove the excess plastic. If you want a better finish you can sandpaper or use a tool like Polysher from Polymaker.

If you have decided us SLA you will see that it can take longer to post-process. Starting by removing the model, it can be a little more complicated than in FDM as residues of resin can remain, hindering the process a little. We must remove the residual resin from the model, by placing the model in a bath of isopropyl alcohol. This must be done delicately using gloves to protect from corrosive substances. After cleaning the model, remove the supports manually or with the help of simple tools.

Stereolithography (SLA) allows for the printing of very complex and precise models.

Price

One of the great differences of both technologies is the difference in price of both 3D printers and its consumables. In the case of an FDM machine can print a RepRap from €200, with filaments at €15-€20 per kilo (though specialized may cost more).

Stereolithography 3D printers can start from €3,000 for a well-reputed machine, and the resins can cost at least €70. In addition, after several uses the printing tank must be changed too.

Models created using FDM technology.

Use In Industry

Due to the difference in prices and quality of both technologies, their use has been concentrated in different sectors. For FDM, its main uses are in rapid prototyping, low cost models, experimentation, education, and the development of models where quality is not as important. Despite this, the technology is improving rapidly and high-quality FDM printers are being developed.

Stereolithography, with a higher quality print, is used in jewelry or other artistic developments due to being able to use castable resins. However is not good for use in models that will be exposed to illumination or heat, since they can change when exposed to sunlight. The dental sector has taken advantage of stereolithography due to its high-quality, precise detailing.

Summary – Pros & Cons:

FDM

- The most widespread desktop technology

- Its mechanism and use is much simpler

- The prices of the 3D printers are more affordable, starting from €200 to €400

- However:

- Requires a thorough calibration to print quality models

- Printing details are often less than in other technologies

SLA

- Due to the quality of its models this technology can be used in multiple sectors

- The different types of resins allow the creation of models with different properties, such as castable resins.

- Models created with this technique offer greater precision and strength

- However:

- The prices of 3D printers of this technology is out of many people’s budgets

- Technical knowledge is required for the usage of the 3D printers.

Which do you prefer, SLA or FDM? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!