How Do You Plan the Path of an FDM 3D Printer Head for Continuous Fiber Composites?

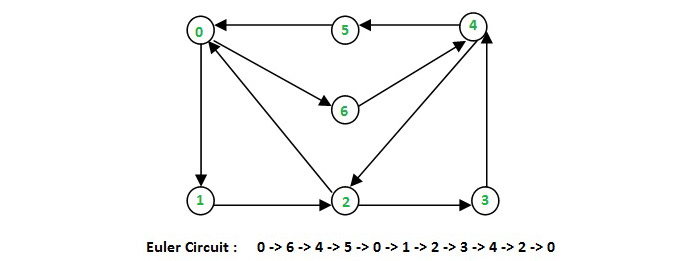

In a recent study, scientists have developed an algorithm in order to plan the path of the head of an FDM 3D printer that uses continuous fiber composites. The goal is to provide a path that prevents intersection points on the same layer as this causes breaks in the fiber bundle contained in the matrix. With this new algorithm, a user could better control composite prints and obtain even more resistant and durable parts. The team at the origin of this project relied on an Eulerian graph and Hierholzer’s algorithm to generate this printing path by integrating different constraints that can be adapted.

Composite materials are popular with additive manufacturing users today because they offer a superior weight to strength ratio, often compared even to metals, without sacrificing geometric complexity. The market has grown rapidly with more manufacturers offering continuous fiber 3D printing solutions. As a reminder, continuous fibers are deposited at the same time as the matrix, hence the need for a specific 3D printer. The short fibers are mixed with the base polymer, which is then extruded by the machine. As you can imagine, each process will have different results but also its own constraints. In continuous fiber 3D printing, the deposition of the fibers creates a greater complexity in terms of both nozzle trajectory and slicing. If too much material is deposited on the same layer, especially at the intersection points, it can break the fiber bundle. Therefore, areas where fibers can intersect should be limited.

The team relied on a Eurelian path as shown above

And this is the point wherein the scientists focused their research. The idea is to generate a single-stroke path, therefore one that is continuous, which would not cut the filament for each layer and therefore create these points of intersection. This printing model gave rise to an Eulerian graph, or a path in a graph that visits ever edge exactly once. Based on Hierholzer’s algorithm, the team was able to determine an optimal printing path for the FDM 3D printer head. Each step in the algorithm corresponds to a single-stroke path. They then printed 3 structures and observed the results with an X-ray scanner, the ScanXmate-L080TT.

For the moment, some small deficiencies have been noted on the curved part of the vertices. The team is therefore in the process of adjusting the parameters of the algorithm to minimize these defects, particularly in terms of fiber alignment or reproducibility of a shape. However, the researchers explain that this calculated trajectory has been designed for complex geometries, with lattice structures. One can imagine how it could be combined with design principles such as topological optimization. If you want to learn more about this project, please read the study published HERE.

What do you think of this new method to optimize a path for carbon fiber reinforced thermoplastics? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

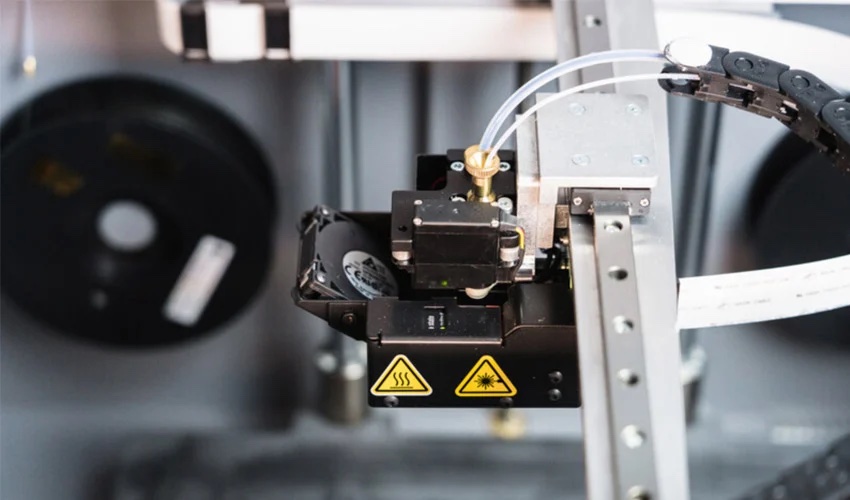

*Cover Photo Credits: Markforged

Thank for your guidance. I got a lot of interesting info here.

Today’s consumers of additive manufacturing choose composite materials because they provide an improved weight to strength ratio, frequently comparable to metals, without sacrificing geometric complexity.