Fast Hydrogel Stereolithography Printing to Revolutionise Organ Transplants

Researchers from the University at Buffalo in New York have developed a way to create large‐scale biocompatible hydrogel models using a fast hydrogel stereolithography printing (FLOAT) method. This method is said to be suitable for printing cells with embedded blood vessel networks, a budding technology expected to be a crucial element of the production of 3D printed human tissue and organs. As of February 2021, over 107’000 people in the U.S. are on a waiting list for an organ transplant. Each day, seventeen of these people die. This is largely due a shortage of donors as well as the low rate (around 0.03%) of deaths which occur in such a way that the organs are preserved well enough to be used in a transplant. As such, methods that rely on artificial alternatives could offer a far more reliable and life saving alternative.

According to University at Buffalo engineers, this discovery marks a step forward in the endeavor to use biotechnology to 3D print human tissue and organs, and ultimately save countless lives which would otherwise have been lost because of a shortage of donor organs.“Our method allows for the rapid printing of centimeter-sized hydrogel models. It significantly reduces part deformation and cellular injuries caused by the prolonged exposure to the environmental stresses you commonly see in conventional 3D printing methods,” explains the study’s co-lead author, Chi Zhou, PhD, associate professor of industrial and systems engineering.

Co-lead authors of the study: Ruogang Zhao, PhD associate professor of biomedical engineering (left) and Chi Zhou, associate professor of industrial and systems engineering (right).

While the fast hydrogel stereolithography printing technology itself is new, the 3D printing of hydrogels has been around for several years and has been at the foundation of several innovations within the additive manufacturing industry, in particular the medical sector, including a new method of administering cancer treatment, and brain implants, among others.. Researchers from Carnegie Mellon were even able to bioprint parts of the human heart using a FluidForm technology, known as FRESH (Freeform Reversible Embedding of Suspended Hydrogels). Hydrogels are of particular use to several sectors, due to the materials’ particular ability to contain water while still maintain solidity and shape. While hydrogels can be produced by 3D printing highly hydrated polymer networks, they are also naturally occurring and can even be found in the human body.

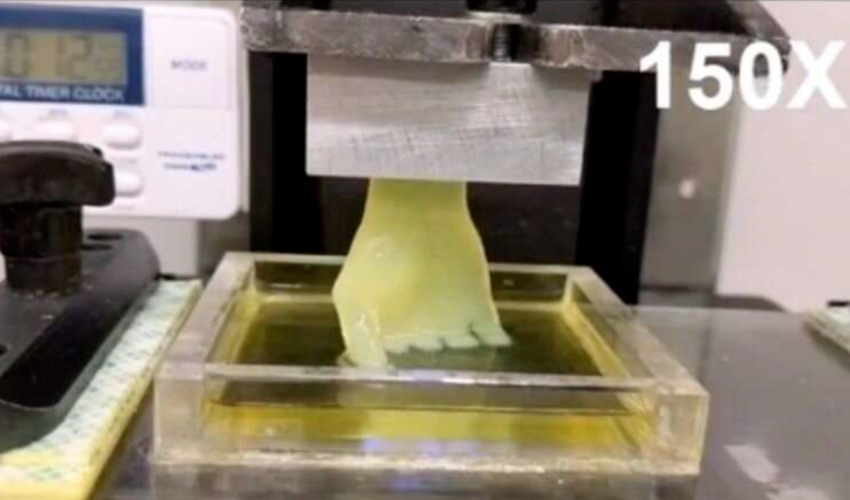

“The technology we’ve developed is 10-50 times faster than the industry standard, and it works with large sample sizes that have been very difficult to achieve previously,” says the study’s other co-lead author Ruogang Zhao, PhD, associate professor of biomedical engineering. While 3D printing a life-size human hand would take around six hours using conventional methods, using this novel technology the researchers were able to do so in nineteen minutes. You can watch this process condensed into seven seconds in the video below:

*All photos courtesy of the University at Buffalo

You can read the study HERE. What do you think about fast hydrogel stereolithography printing? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!