Australian micro-factory is set to turn electronic waste into a 3D printing filament

The Center for Sustainable Materials Research and Technology (SMaRT Center) at the University of New South Wales (UNSW) in Australia has announced the opening of a micro-factory that will be dedicated to the recycling of electronic waste. This factory will give a new life to the recycled waste by turning it into 3D printing filaments, thus helping to reduce the environmental impact of electronic consumer goods on our planet.

There are currently many projects that are trying to combine 3D printing and ecology in order to offer products or services that are more environmentally friendly. Whether that be with automobiles, corporate recycling solutions, or more natural composite materials. Some similar initiatives being taken in other parts of the world can be seen with the 3D printing of street furniture from the plastic waste of Amsterdam’s inhabitants to Armor 3D with their range of recycled and recyclable OWA filaments.

Recycling waste to create value

According to a study conducted by the United Nations University, Oceania produced 15.2 kg of electronic waste per capita in 2014. This electronic waste would have increased by 63% between 2010 and 2015, reaching a total of 12.3 million tons. This micro-plant project could be a response to this alarming increase and offer a more virtuous electronic product lifecycle by creating value rather than just producing toxic waste for our environment. The latter would be transformed into a 3D printing filament, making it possible to manufacture other useful objects for the consumer.

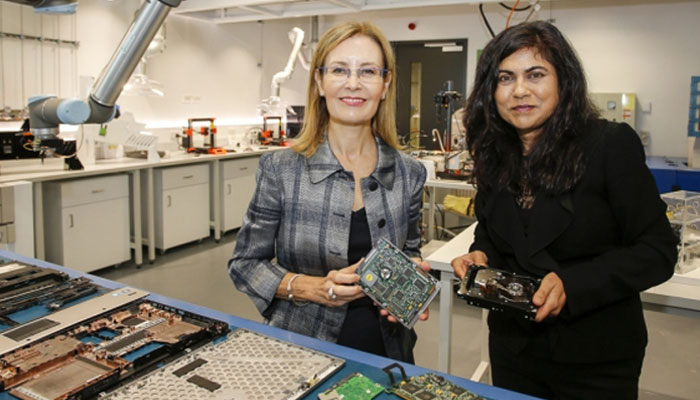

“Our e-waste micro-factory and another under development for other consumer waste types offer a cost-effective solution to one of the greatest environmental challenges of our age, while delivering new job opportunities to our cities but more importantly to our rural and regional areas, too,” says Professor Veena Sahajwalla, Director of the SMaRT Center. “Using our green manufacturing technologies, these micro-factories can transform waste where it is stockpiled and created, enabling local businesses and communities to not only tackle local waste problems but to develop a commercial opportunity from the valuable materials that are created.”

Professor Veena Sahajwalla presents Australian Minister for the Environment, Gabrielle Upton, with the micro-factory

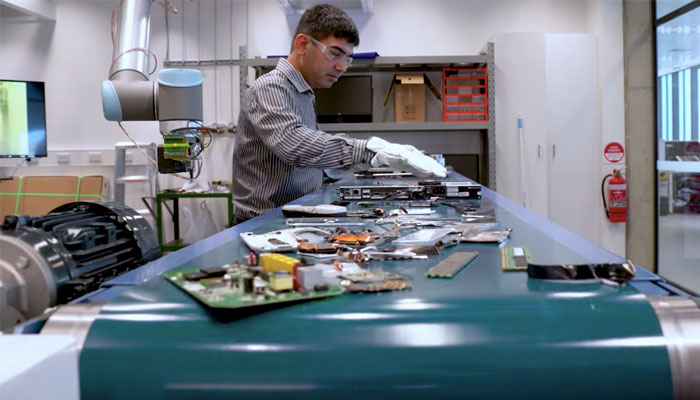

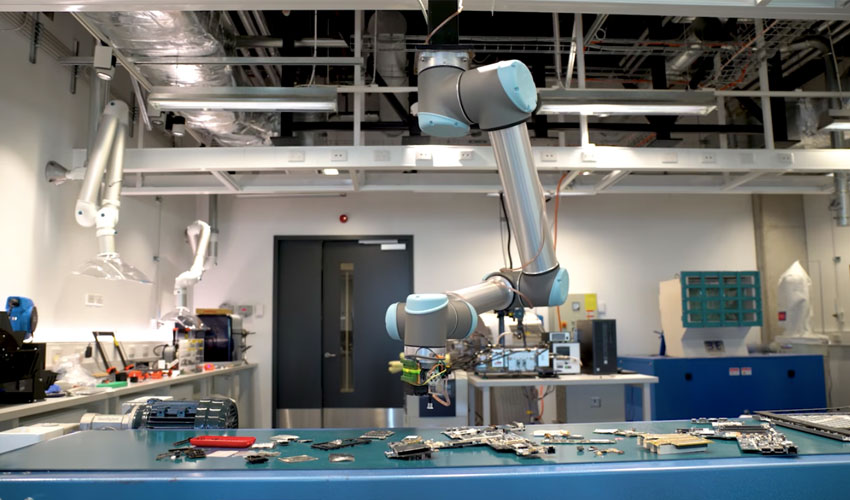

These micro-factories could be integrated into sites as small as 50 square meters, thanks to their modular design, which allows for a high level of flexibility and adaptability. There would also be a number of different modules depending on the type of waste treated and its ultimate usefulness. For example, laptops and smartphone cases would first be broken down, and then a robot would identify the useful elements among the waste. Another module would be to use a small furnace to turn these parts into materials, using a precisely controlled temperature process.

Other modules would be specific to the type of raw material processed. Metal alloys recovered from printed circuit boards would be reused to make metal components for various manufacturing processes. The plastic waste, in turn, would be converted into different filaments that would be able to be used on FDM printers.

The University explains that it is continuing its development work and is seeking different partnerships with companies and associations. More information can be found in the video below or on the university’s official website.

What do you think of this initiative? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!