The extrusion temperature influences particles emitted during printing

What is the effect of the temperature of the 3D printing nozzle on the emission of toxic particles during the manufacturing process? This is the subject of new research conducted at Seoul National University: a team of scientists has tested several so-called classic polymers – PLA, ABS and nylon – at different extrusion temperatures. They found that the higher the temperature, the higher the rate of particle emissions. The extrusion temperature is therefore an important factor to take into account in order to operate your FDM 3D printer safely.

As we told you just last week, one of the hazards of FDM 3D printing is the emission of potentially toxic particles, volatile organic compounds (VOCs) that can pose a health risk to the user if exposed for too long. This is why manufacturers recommend the use of a filtration solution, or to operate their machine in a dedicated space. But what will affect this rate? What are the factors to consider when trying to lower emissions? We know that the polymer used will have a more or less important effect on the quantity of particles emitted, but also the temperature of the tray or chamber. This is partly why manufacturers recommend parameters, whether to facilitate the printing process or to guarantee a certain degree of security. The Korean researchers wanted to go further in determining these factors by looking specifically at the temperature, especially that of the extrusion process.

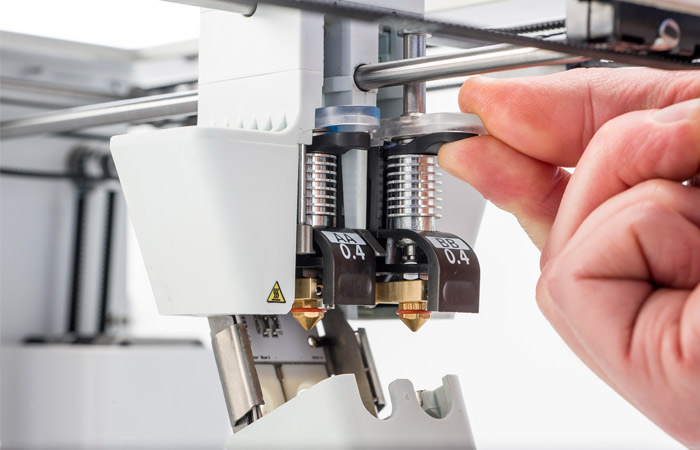

Credits: Ultimaker

What is the effect of variation in extrusion temperature?

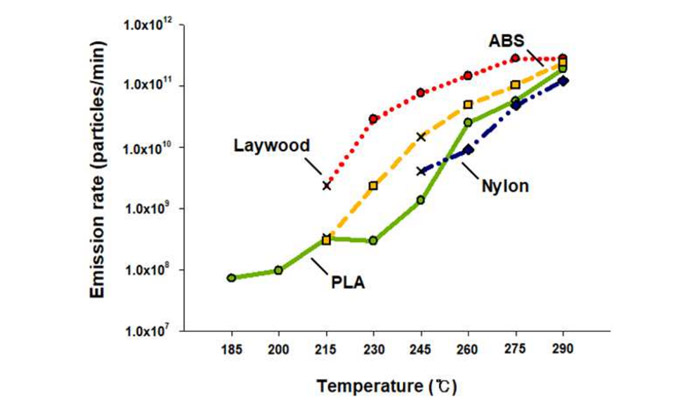

The researchers explain that they worked with machines with closed enclosures to avoid temperature fluctuations and to accurately measure particle counts. They tested 4 different materials, PLA, nylon, ABS and wood-filled PLA: each filament was used twice to produce a total of 8 cubes by varying the temperature. The temperature was between 185°C and 290°C, with intervals of 15°C at each fluctuation.

Scientists used a particle calibrator and an optical particle spectrometer at one-minute intervals to monitor emissions in real time at each temperature. This allowed them to measure the number of particles per unit volume as well as their size. They explain that it allowed them to determine the emission rates for each filament at each temperature.

As the temperature rises, the rate of particle emissions increases.

The results obtained are quite clear: every time the temperature range increases, the rate of emission of harmful particles increases, regardless of the material used. The study shows that the rate is about 107 to 109 particles emitted per minute at low temperatures, while at the highest temperature, 1,011 particles are emitted per minute. The user must therefore take care to minimise his extrusion temperature as much as possible to ensure his safety. You can find more information HERE. Did you know that extrusion temperature affects the emission of particles? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter to receive all the latest 3D printing news straight to your inbox!