ExtrudeX: A DIY Machine for Turning Your Plastic Waste into Printing Filament

While 3D printing saves material by only depositing it where it is needed, it still generates waste. What do you do with failed prints, filament scraps, or parts you want to throw away? The young company Creative3DP, led by Priyank Pal, has come up with ExtrudeX, an affordable and easy-to-use machine designed to solve this problem. The idea is to transform all this plastic waste into reusable filament, directly from your workshop or home. Launched and funded on Kickstarter, this project, which can be 3D printed at home, has been a resounding success, proving that it is possible to close the loop!

The idea of such a machine is not new, and a few names come to mind, such as the Dutch company 3devo. Solutions like these are very interesting because they promote recycling, the circular economy, and short local supply chains that allow for complete autonomy. So, how is ExtrudeX different?

ExtrudeX is meant to be easy to use and accessible.

ExtrudeX: Key Characteristics

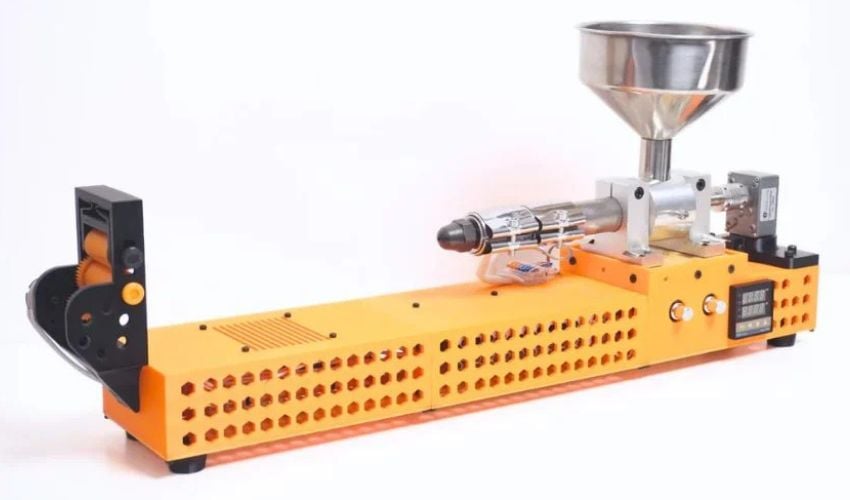

According to its creator, the main aim is to offer a more compact, lightweight machine that is suitable for makers and home environments. ExtrudeX is 65 cm long and can therefore be easily placed on a table next to your FDM printer, for example. It also has a side handle, making it easy to transport.

But what is particularly interesting is that it can be built at home. It is made up of several 3D-printed parts, such as the chassis and the extraction system. It is cheaper to manufacture and can be easily repaired if a component breaks or wears out. Other parts, such as the motor and electronic components, can be easily purchased locally. The advantage of a DIY machine is that you understand how it works much better, making it easier to use every day.

In terms of materials, ExtrudeX can process support materials, failed prints, and clean granules: everything can be mixed together to create a printing filament. Note that only PLA, ABS, and PETG are currently compatible.

Easily adjust the machine according to the plastic to be processed

How Does it Work?

In practical terms, how does the Extruder work? There are six steps:

- Cut your plastic waste with a shredder or scissors;

- Heat your ExtrudeX according to the plastic used;

- Place your cut plastic in the hopper;

- Start the motor;

- Insert the extruded strand into the extraction mechanism;

- Wait for it to cool and collect the filament.

Creative3DP recommends mixing 40% shredded waste with 60% virgin plastic pellets, always using the same material. For instance, you would use your PLA scraps with PLA pellets.

The Kickstarter campaign has already ended, and the machine can be purchased on the Creative3DP website for $249. We invite you to visit the page HERE to find out more, as it is currently out of stock.

What do you think of ExtrudeX? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: Creative3DP