ExOne’s New Metal Adoption and Application Center in Europe Provides One-Stop Shop for All Binder Jetting Needs

ExOne, an industrial leader in binder jetting systems with a portfolio of both metal and sand 3D printers, has expanded its application and adoption center (EAC) in Europe. Now the 2,070-square-meter center will offer direct metal binder jet 3D printing as well as their existing sand printing service. Though ExOne already has metal adoption centers in the United States and Japan, this is the first time that one is available in Europe, marking the combination of two pillars of ExOne’s services, the German-developed sand business and the American-born metal business. The metal center will provide a complement to existing sand centers already in the region and will help show customers the benefits of metal binder jetting, especially for industries like the metal injection molding sector.

Discussing the importance of having this new center, Eric Bader, the General Manager, stated, “We see the demand on the market to have an adaptation and application center in Europe. All kinds of markets think and behave differently and we have it in the States for example, but the flexibility we gain through the EAC located in Germany is of huge-value. Customers can really come to us, especially in this pandemic when it’s more complicated than before, and with the EAC they can see the technology live.” With the opening of this newest expansion, there will be a center located in Europe wherein the entire process chain is under one roof. This is a significant benefit for customers on the continent as previously it was necessary to ship parts from the States, delaying the entire process. Now anyone will be able to discover binder jetting for each stage of the process, including debinding and sintering.

Eric Bader, the General Manager ExOne GmbH, with some of the ExOne printers available at the center

ExOne notes its true purpose lies in introducing users to ExOne’s binder jetting technology and how they can be optimized and used in innovative ways. ExOne has seen the growing interest in binder jetting and its applications, and by expanding to the metal EAC, they can help foster that interest by providing a risk-free space for users to test how binder jetting can be beneficial to them. Thanks to experts in a variety of fields, including material science, post-processing and more, customers will be helped at each step of the process. With this center, ExOne now offers both sand and metal binder jetting through their EACs in Europe and the United States.

Differences between sand and metal printing and their applications

Though ExOne is known for both, there are some distinct differences between sand and metal binder jetting, notably in their applications. Which makes the expansion of the application and adoption center in Europe even more appropriate. For example, sand binder jetting is more of an indirect process. It is often used to create cores and molds for tooling, serial production is also possible. Metal binder jetting by contrast is good for manufacturing small and medium parts in high quantities. The ExOne Binder Jetting Family (Sand + Metal) is capable to cover metal parts from a few gram to hundreds of kilos which offers the customer a huge range and flexibility.

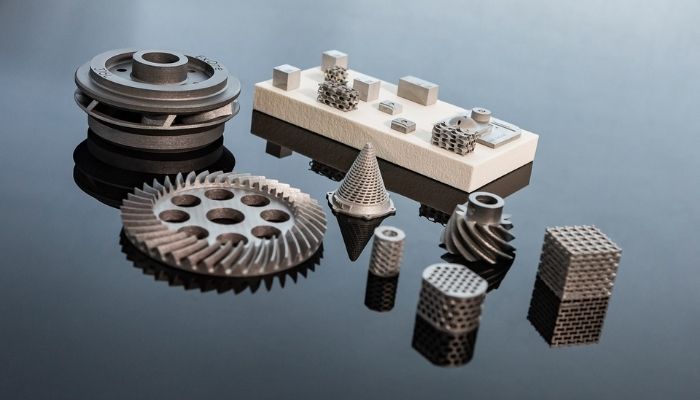

Examples of some of the finished parts that can be made at the new expanded EAC

Thanks to an EAC that deals with metal as well as the existing sand center, ExOne is enabling customers from a variety of industries. Oliver Hanitzsch, Regional Sales Manager, expanded, “It’s interesting because we are not limited to industries! Right now there are customers from all kinds of industries: medical, luxury, sports, automotive all kinds of sectors. There is a horizontal cut through all these industries and that makes it interesting because you get up in the morning and don’t know what application you will be approached with.”

The use of binder jetting for the metal injection molding industry

One of the main draws for the new metal EAC is its use for the metal injection molding industry. Often, metal additive manufacturing is compared to injection molding in terms of the parts created and which is better to use. Though the new metal center is not expected to replace the use of metal injection molding in the region, ExOne believes it will prove the importance of metal binder jetting as a tool.

Experts in a variety of fields work at the expanded EAC, helping customers to understand what they need for their projects

As you may know, one aspect of AM that is attractive to many metal manufacturers is that contrary to metal injection molding, users using metal AM do not need to make a tool before starting manufacturing, significantly reducing the time needed to make the part and thus saving money. With processes like metal binder jetting, parts can be made almost immediately after they are designed and optimized.

Additionally, according to the company, the metal adoption and application center will be especially attractive for customers that need parts in different sizes, as they do not need to make a mold which might only be used once. Agility is the main benefit of metal AM for this particular sector, as by using ExOne’s technology, users will be able to make multiple iterations in the time that usually would be spent making a specific tool. With the metal EAC in Europe, MIM customers will be able to experiment with binder jetting and see how it could be interesting for their own business and manufacturing processes. For example, creating tools with internal cooling channels, thus increasing the quality of the process. You can learn more about the metal ExOne adoption center on ExOne’s website HERE or in the video below.

What do you think about ExOne’s newest metal application and adoption center in Europe? Let us know in a comment below or on our Facebook, Twitter, and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!